Energy-saving and anti-seismic integral wall panels for building industrialization

A building wall and overall technology, which is applied in the direction of buildings, building materials, building components, etc., can solve the problems of building walls that cannot resist earthquakes, slow construction speed, and high labor intensity, so as to reduce earthquake damage, reduce weight, and reduce construction costs. garbage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

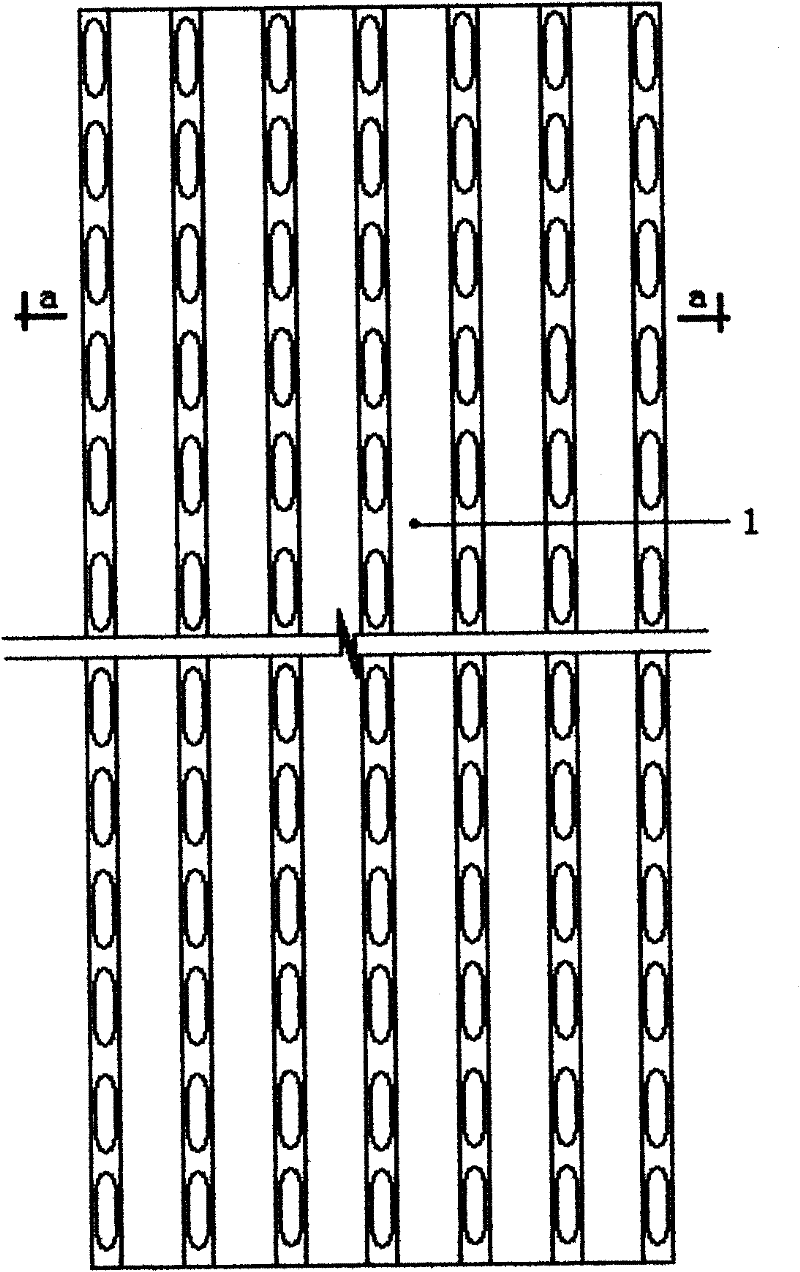

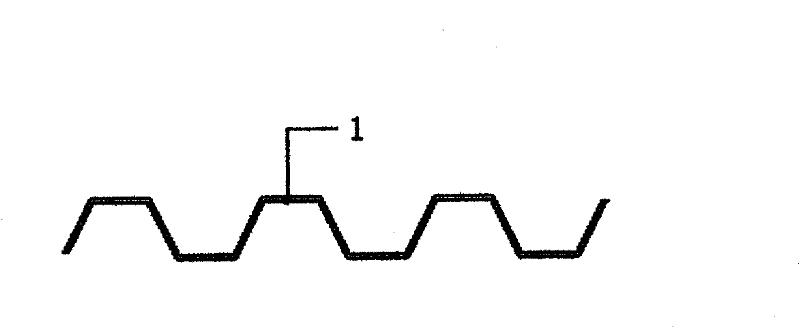

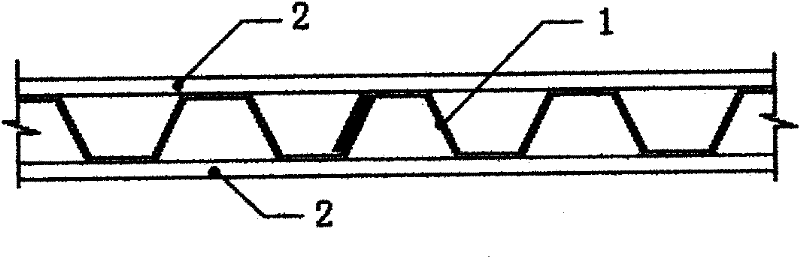

[0042] Embodiment 1: In public buildings with industrialized steel structures, the outer walls of the buildings adopt " Figure 4 " and " of Figure 9 "Wall structure, the interior wall adopts" image 3 "with" Figure 10 "Wall structure, the corrugated inner keel board (1) is made of 1.0mm thick galvanized steel plate, the energy-saving sound insulation board (3) is made of 30mm thick extruded board, and the panel (2) is made of 8mm thick fiber silicon calcium board. After the invention of the wall, the weight of the wall does not exceed 35 kg per square meter, the weight of the building can be reduced by 25%, and the construction cost can be saved by more than 25%. The energy-saving layer of the outer wall of the building completely wraps the steel structure to form a whole The outer thermal insulation (or heat insulation) layer, the building wall will never collapse in the earthquake, and the seismic capacity of the building structure is also greatly improved, so that the ...

Embodiment 2

[0043] Embodiment 2: In industrial industrialized steel structure residential buildings, the outer walls of the buildings adopt " Figure 4 " and " of Figure 9 "Wall structure, the interior wall adopts" Figure 5 "Wall structure, the corrugated inner keel board (1) is made of 0.5mm thick galvanized steel plate, the energy-saving sound insulation board (3) is made of 20mm thick extruded board, and the panel (2) is made of 6mm thick fiber silicon calcium board. After the invention of the wall, the weight of the wall does not exceed 30 kg per square meter, the weight of the building can be reduced by more than 30%, and the construction cost can be saved by more than 35%. The energy-saving layer of the outer wall of the building completely wraps the steel structure to form a whole The external thermal insulation (or thermal insulation) layer, the indoor room can form an independent energy-saving system, which is very suitable for residential buildings with non-integral air-condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com