Branched molten polycarbonate with low defect structure

一种聚碳酸酯、熔融酯交换的技术,应用在支化芳香族聚碳酸酯领域,能够解决没有提及支化点与氧杂蒽酮结构比例等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

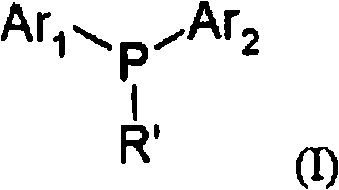

[0083] Examples of catalysts suitable for the preparation of polycarbonates according to the invention are those compounds represented by the general formula (VII):

[0084]

[0085] in:

[0086] R 9 , R 10 , R 11 and R 12 denote the same or different C independently of each other 1 -C 18 Alkylene moiety, C 6 -C 10 aryl moiety, or C 5 -C 6 a cycloalkyl moiety, and

[0087] x - Represents an anion, where the corresponding acid-base pair H + +X - → pK of HX b Values less than 11.

[0088] The preferred catalyst is tetraphenyl Fluoride, tetraphenyl tetraphenyl-borate and tetraphenyl phenoxide. Most preferably tetraphenyl phenoxide. An example of a preferred content of salt catalyst is 10 -2 to 10 -8 mol per mol of diphenol, and the most preferred content of catalyst is 10 -4 to 10 -6 mol per mol of diphenol.

[0089] Polycarbonate can be prepared in steps, the temperature can be controlled step by step in the range of 150 to 400 °C, the residenc...

Embodiment

[0197] Characterization of the Molding Compositions According to the Invention (Test Methods)

[0198] Melt viscosity

[0199] Rheological properties by measuring the melt viscosity of the molding composition according to the invention in [Pa s] at 320°C as a function of the shear gradient (η) varying from 100 to 1000 [1 / s] To measure. The measurement is done with a capillary rheometer according to ISO11443.

[0200] Determination of relative viscosity ( n rel.):

[0201] The relative solution viscosity ηrel. is determined in dichloromethane (0.5 g polycarbonate / l) at 25° C. in an Ubbelohde viscometer.

[0202] Average molecular weight (Mw)

[0203] The average molecular weight Mw is determined from a 0.2% strength solution of the polymer in dichloromethane by gel permeation chromatography (GPC) and UV detection. GPC is calibrated by linear PC standards.

[0204] Melt volume flow rate (MVR)

[0205] The melt volume flow rate (MVR) is measured according to ISO...

Embodiment 23

[0244] Compounding materials comprising phosphines or phosphites and if appropriate sterically hindered phenols (Examples 12, 22-24) are significantly more stable during heat aging than Example 11 containing no additives, as can be seen from ΔYI 1000h worth seeing. Unexpectedly, Example 23, which contained an aromatic phosphite, was more effective than Example 23, which contained a combination of phosphine and n-octadecyl 3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate. 24 is superior in yellowing. This characteristic could not have been foreseen according to the German published application DE 10 2009 043509.3, which was not published at the filing date of the present application. Said unpublished publication at the filing date of the present application describes THPE-free MeltPCs in which phosphine is combined with n-octadecyl-3-(3,5-di-tert-butyl-4-hydroxyphenyl)propane The combination of esters provides the best anti-yellowing effect during heat aging and is superior to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com