Die box tuning roll device on straight wire drawing machine

A straight wire drawing machine and mold box technology, applied in the field of tuning devices, can solve problems such as inflexible rotation of the rotating shaft, ineffective rotation of the swing arm of the tuning rod, and inability to inject grease, so as to avoid serious deformation of the rotating shaft and even damage to the equipment. Accidents, improving the equipment start-up rate and product yield, reducing the effect of maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific drawings.

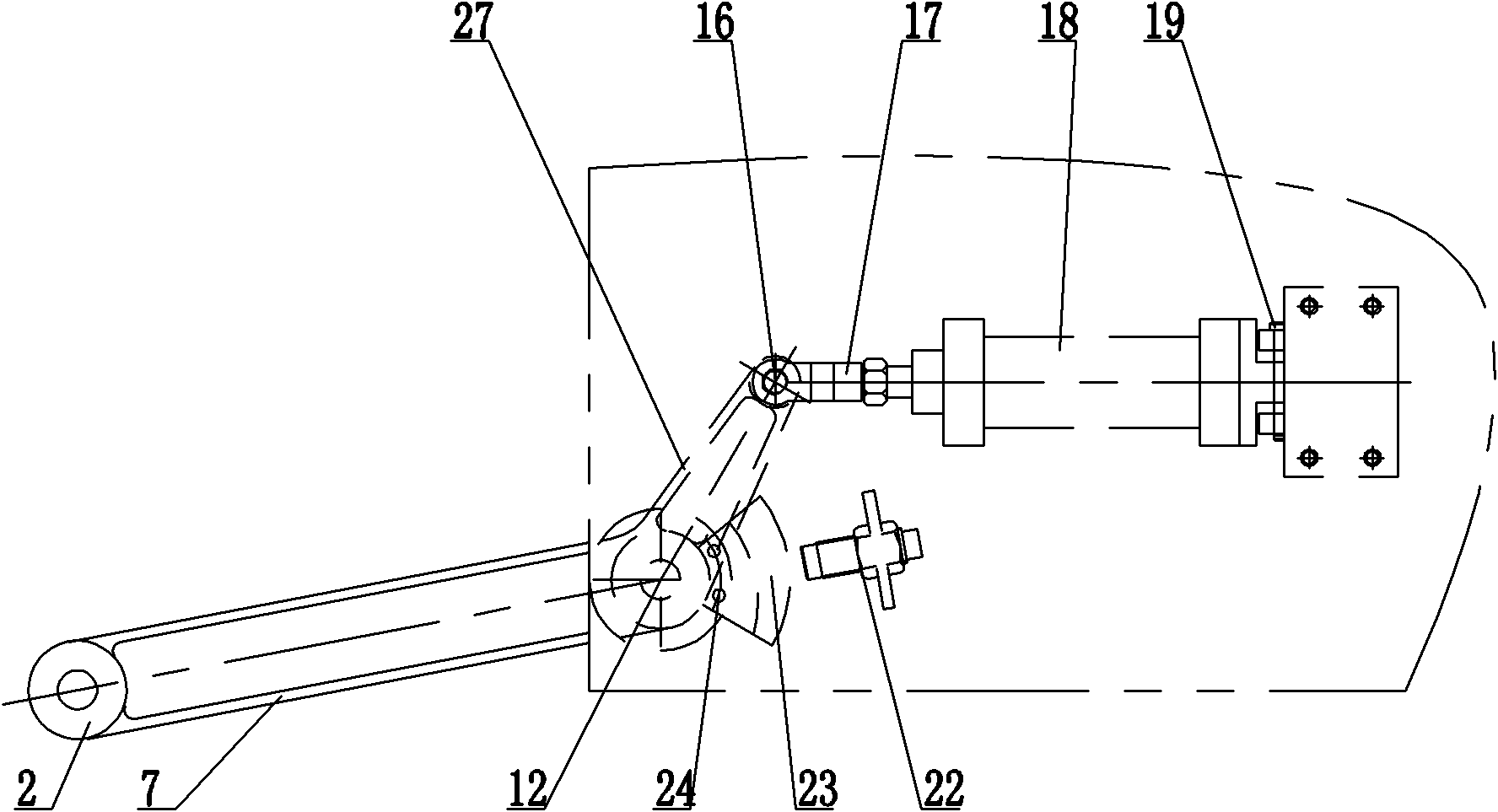

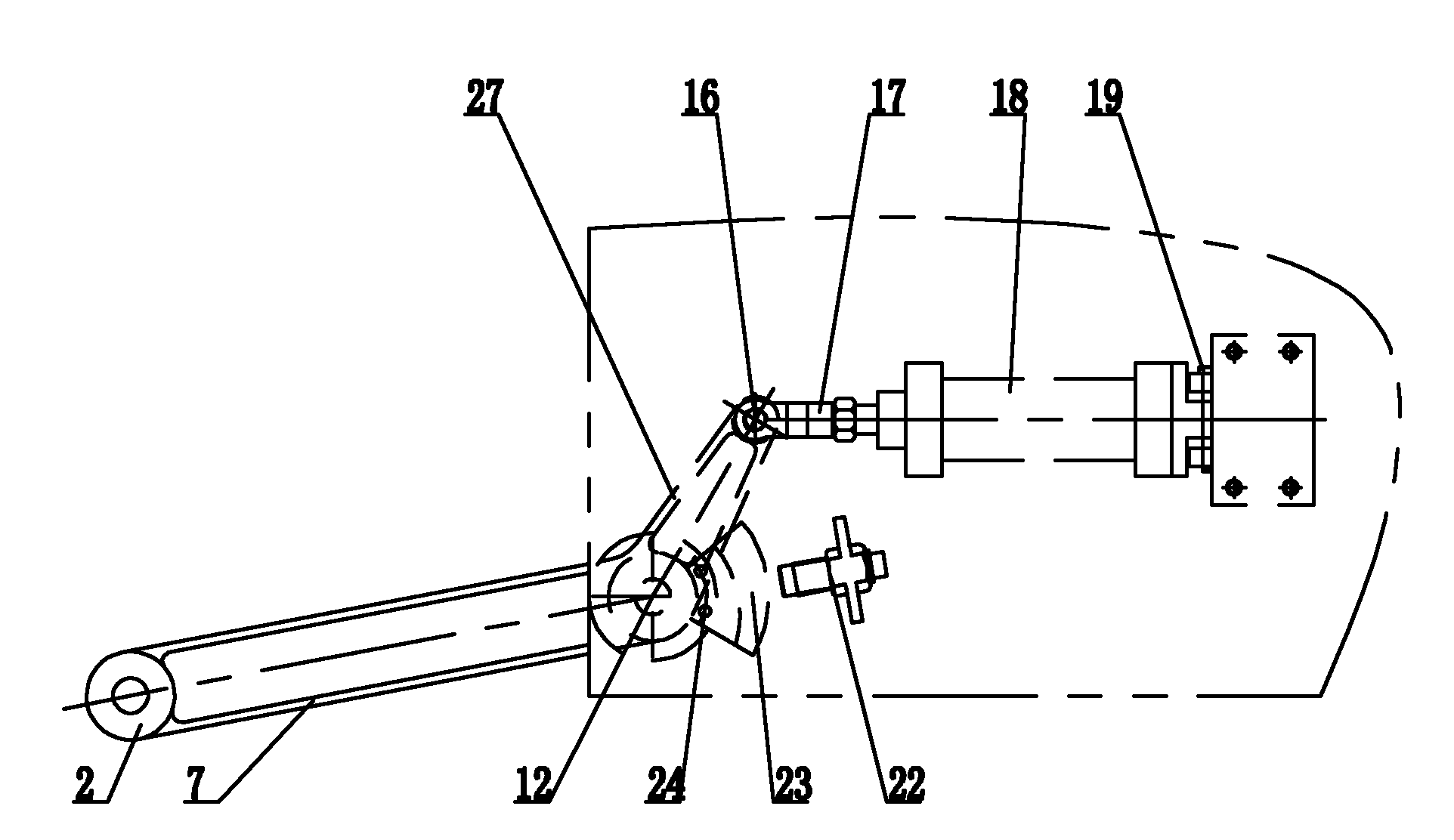

[0017] Such as Figure 1 ~ Figure 2 Shown: the mold box tuning roller device on the straight wire drawing machine includes nut 1, guide roller 2, bearing cover 3, guide roller shaft 4, first bearing 5, shaft retaining ring 6, swing arm 7, first bolt 8 , gland 9, second bearing 10, first bearing spacer 11, rotating shaft 12, round nut 13, second bearing spacer 14, hole retaining ring 15, first pin 16, Y-shaped joint 17, cylinder 18 , The second pin shaft 19, the fixed seat 20, the second bolt 21, the displacement sensor 22, the cam 23, the screw 24, the mold box mounting plate 25, the rotating shaft sleeve 26, the connecting rod 27 and the like.

[0018] The present invention includes a rotating shaft 12 and a cylinder 18 installed on the lower end surface of the mold box mounting plate 25, a rotating shaft sleeve 26 is sleeved on the rotating shaft 12, and the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com