A yellow phosphorus tail gas purification system

A purification system, a technology for yellow phosphorus tail gas, applied in the direction of combustible gas purification, combustible gas purification/transformation, gas dust removal, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

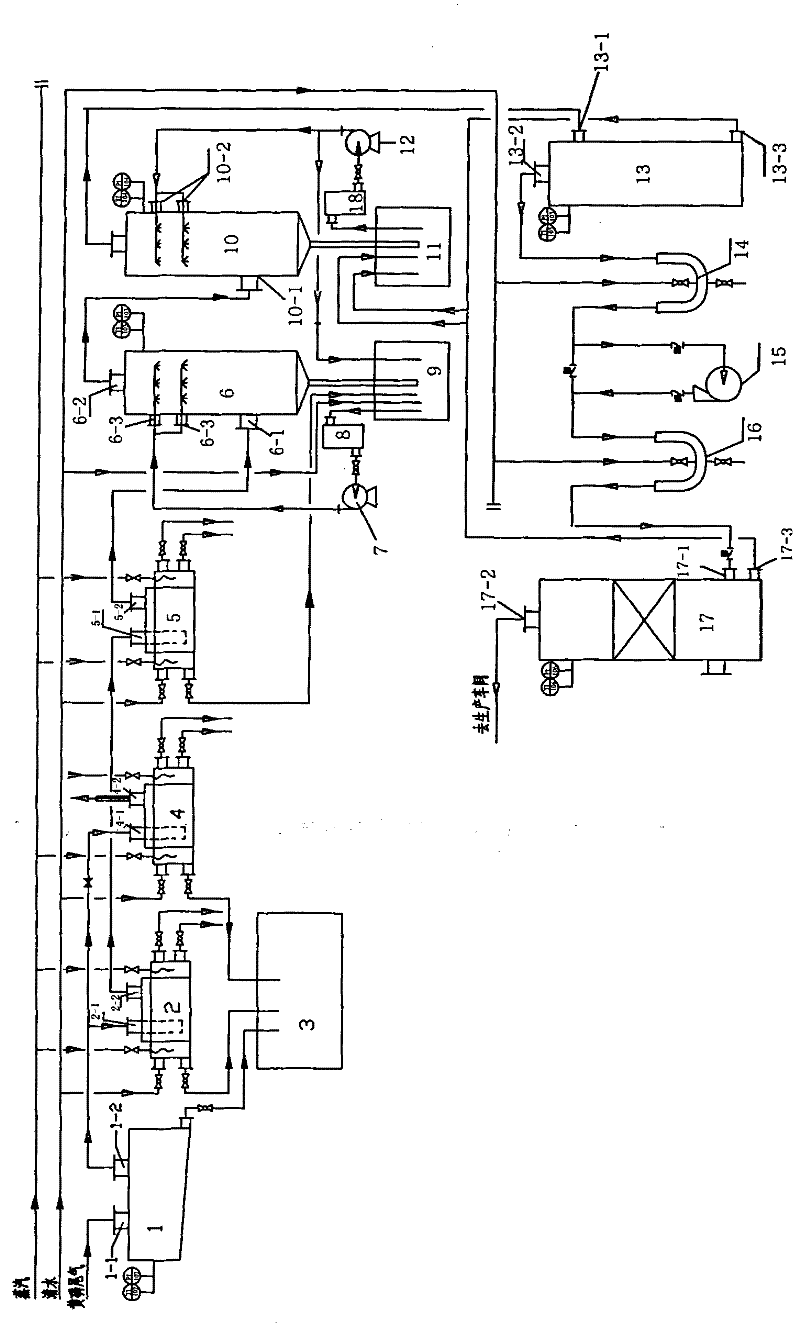

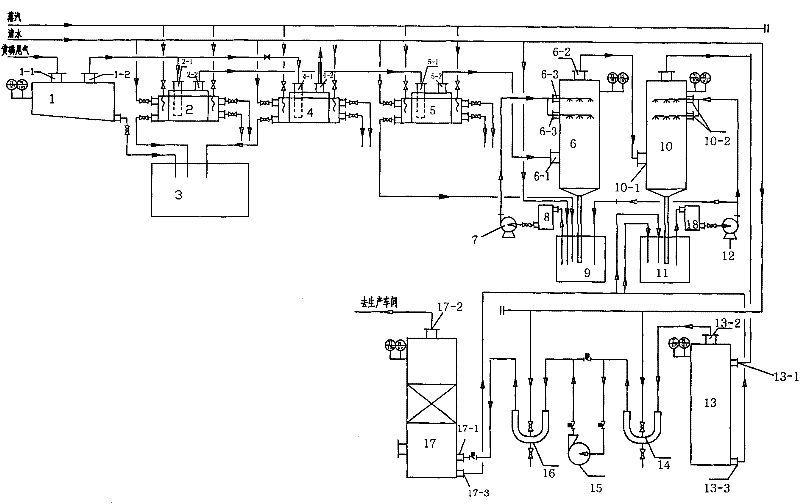

[0019] A yellow phosphorus tail gas purification system, the system includes a gas separator 1, a first-level safety water seal 2, a second-level safety water seal 4, a third-level safety water seal 5, an alkali washing tower 6, a water washing tower 10, and a cyclone 13 , a first-level U-shaped water seal 14, a second-level U-shaped water seal 16, and a water vapor separator 17. The system includes a gas separator 1, a first-level safety water seal 2, a second-level safety water seal 4, a third-level safety water seal 5, an alkali washing tower 6, a water washing tower 10, a cyclone 13, and a first-level U-shaped water seal 14 , secondary U-shaped water seal 16, water vapor separator 17; wherein the air inlet 1-1 of the gas separator 1 is connected with the yellow phosphorus tail gas pipeline, and the gas outlet 1-2 of the gas separator 1 is respectively connected with the primary safety water seal The air inlet 2-1 of 2 is connected with the air inlet 4-1 of the secondary sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com