Thermally Optimized Automotive Power Supply

A technology for power supply devices and automobiles, applied in battery/fuel cell control devices, electric vehicles, circuits, etc., can solve problems such as the complex structure of drive battery packs, achieve simple structure, promote temperature distribution, and reduce design costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

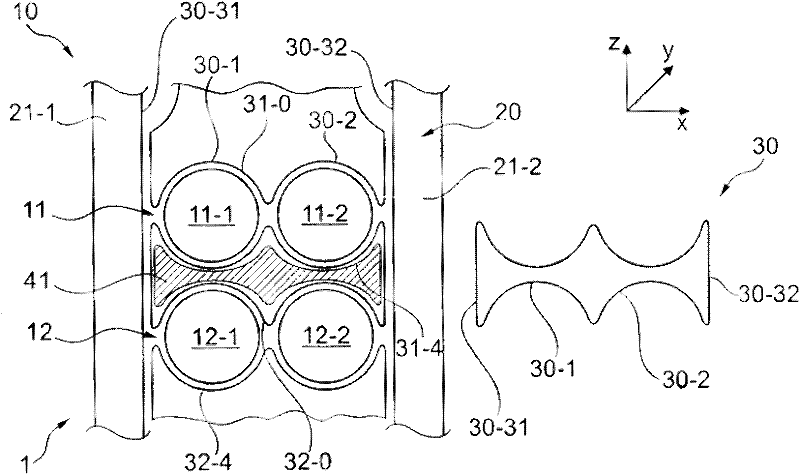

[0035] Functionally identical components are provided with the same reference symbols in the figures. The figures only show the basic design of the power supply device according to the invention, and the individual components of the device are not necessarily drawn to scale.

[0036] Figures 1 to 4 A device 1 according to the invention for powering a motor vehicle, in particular a passenger car or a motorcycle, is shown in a schematic cross-sectional view. The power supply device 1 comprises a battery arrangement 10 with a certain number of batteries and / or double-layer capacitors 11-1, 11-2, 12-1, 12-2. To simplify the description below, only cells or batteries are referred to. However, it is not restricted thereto, rather the battery or the battery pack can also be replaced by a double layer capacitor or a double layer capacitor pack.

[0037] exist figure 1 In the first exemplary embodiment of FIG. 2 , two battery packs 11 , 12 are shown, which are arranged one above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com