Initiation Control Method for Reducing Blasting Vibration Effect

A blasting vibration and control method technology, which is applied in the field of blasting, can solve the problems of aggravated blasting vibration hazards, large delay errors, and low delay accuracy, and achieve the effect of reducing blasting vibration effects and reducing blasting vibration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

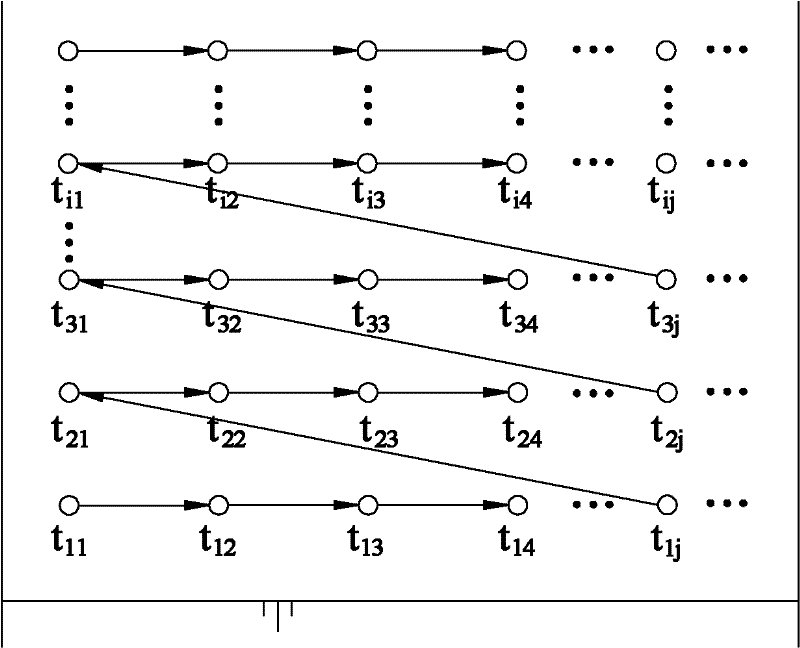

[0016] In the layout of the detonation network, the blastholes are divided into many rows according to their geographical location and detonation sequence. The detonation time difference between the detonators of adjacent holes in the same row is the delay between holes, and the detonation time difference of the detonators of adjacent holes in the same row is The delay time between holes is the same.

[0017] The time difference between detonating detonators between corresponding blastholes in adjacent rows in the detonating network is the inter-row delay.

[0018] Let the delay between holes be ΔT i , whose calculation formula is:

[0019] ΔT i = t i,(j+1) -t ij (i=2, 3, 4, . . . , j=1, 2, 3, . . . )

[0020] In the formula: i represents the row number, j represents the jth blast hole, t ij is the detonation time of the i-th row j-th blasthole in the detonation network, in milliseconds; t i,(j+1) is the detonation time of the (j+1)th blast hole in the i-th row in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com