Double-cone hole flat alloy chute lining

A technology of alloy chute and taper hole, which is applied to blast furnace parts, furnaces, blast furnace details, etc., can solve the problems of large overall area, easy to break or fall off, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

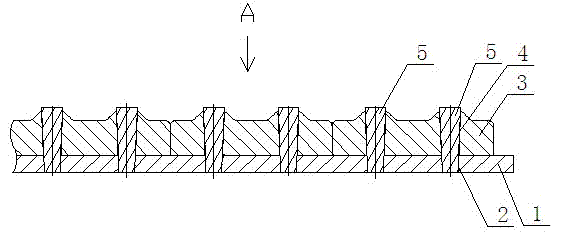

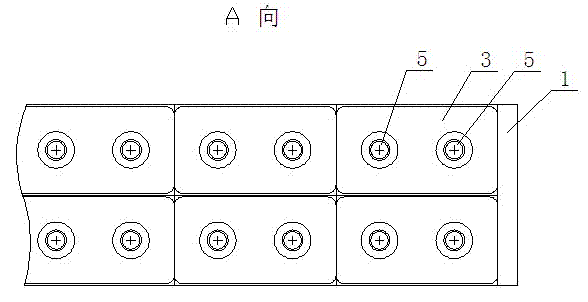

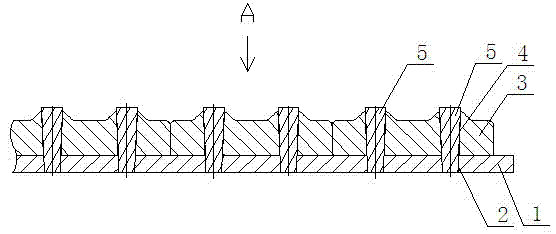

[0008] Such as figure 1 , 2 As shown, it is a double-cone hole-type flat alloy chute lining, including several steel substrates 1, and several hard alloy blocks 3 are respectively arranged on each steel substrate 1, and two second carbide blocks 3 are respectively arranged on each hard alloy block 3. A bolt hole 4, second bolt holes 2 equal in number to the first bolt holes 4 are respectively arranged on each steel substrate 1, the first bolt holes 4 and the second bolt holes 2 are provided in one-to-one correspondence, each Conical pins 5 are respectively inserted in the first pin holes 4, and the big ends of each truncated pin 5 are respectively arranged on the side of the cemented carbide block 3 away from the steel substrate 1, and each truncated pin 5 The small ends of the pins are respectively arranged in the corresponding second pin holes 2 and welded with the steel matrix 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com