Stamping die

A technology of stamping dies and punches, which is applied in the field of molds, and can solve problems such as unstable clamping of punches, clamping heads, and short service life of clamping dies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

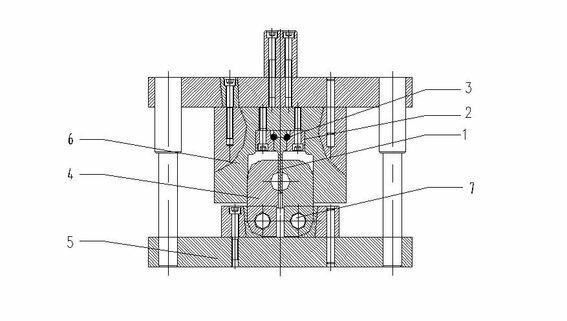

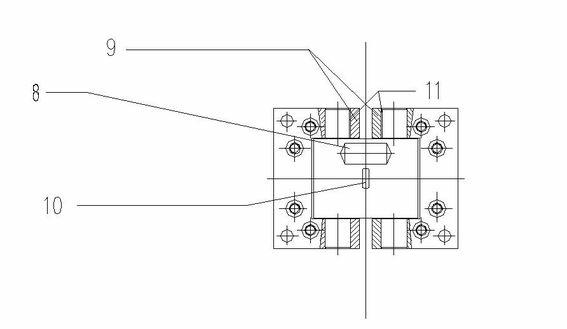

[0024] A stamping die, comprising a punch body, a fixed sleeve and a fixed pin, two movable molds arranged in opposite directions in the longitudinal direction, an insert, a lower mold base, two upper fixed blocks, a spring, and two rotating shafts, the fixed sleeve is provided with a concave One end of the punch body is embedded in the groove, and two symmetrical first arc-shaped grooves are opened on the punch body embedded in the groove, and on the side of the groove corresponding to the arc-shaped groove The wall is provided with a concave second arc-shaped groove, the first arc-shaped groove on the punch body and the second arc-shaped groove on the wall of the groove form a through hole, and the fixed pin cooperates with the through hole to make The punch body is fixed in the groove, the two upper fixed blocks are fixedly connected to both sides of the fixed sleeve, one end of the two movable molds is respectively connected to the lower mold seat through the rotating shaft...

Embodiment 2

[0026] A stamping die, comprising a punch body, a fixed sleeve and a fixed pin, two movable molds arranged in opposite directions in the longitudinal direction, an insert, a lower mold base, two upper fixed blocks, a spring, and two rotating shafts, the fixed sleeve is provided with a concave One end of the punch body is embedded in the groove, and two symmetrical first arc-shaped grooves are opened on the punch body embedded in the groove, and on the side of the groove corresponding to the arc-shaped groove The wall is provided with a concave second arc-shaped groove, the first arc-shaped groove on the punch body and the second arc-shaped groove on the wall of the groove form a through hole, and the fixed pin cooperates with the through hole to make The punch body is fixed in the groove, the two upper fixed blocks are fixedly connected to both sides of the fixed sleeve, one end of the two movable molds is respectively connected to the lower mold seat through the rotating shaft...

Embodiment 3

[0028] A stamping die, comprising a punch body, a fixed sleeve and a fixed pin, two movable molds arranged in opposite directions in the longitudinal direction, an insert, a lower mold base, two upper fixed blocks, a spring, and two rotating shafts, the fixed sleeve is provided with a concave One end of the punch body is embedded in the groove, and two symmetrical first arc-shaped grooves are opened on the punch body embedded in the groove, and on the side of the groove corresponding to the arc-shaped groove The wall is provided with a concave second arc-shaped groove, the first arc-shaped groove on the punch body and the second arc-shaped groove on the wall of the groove form a through hole, and the fixed pin cooperates with the through hole to make The punch body is fixed in the groove, the two upper fixed blocks are fixedly connected to both sides of the fixed sleeve, one end of the two movable molds is respectively connected to the lower mold seat through the rotating shaft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com