Dust bucket

A technology of dust collection bucket and dust, which is applied in the field of dust collection bucket, which can solve the problems of inconvenient daily use, poor sealing of the bottom of the dust collector, dust leakage, etc., achieve high dust discharge cleanliness, avoid re-pollution and unpleasantness, The effect of low operating point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 3 example

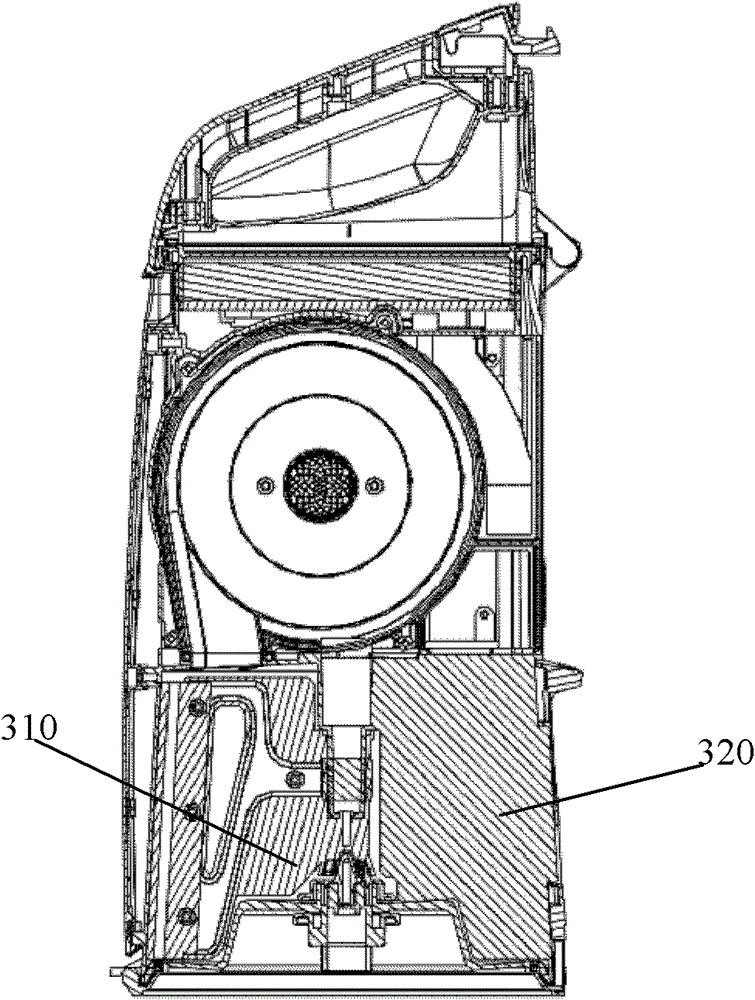

[0050] The chassis is fixed above the bottom plate of the base, that is, compared with the first embodiment, the annular grooves 38, 39 are formed above the bottom plate of the base, preferably, it only needs to set an inner circular Annular groove, and the chassis is buckled between the cylindrical side wall 29 and the inner circular annular groove and a narrow cavity that can accommodate the sliding slider 30 is formed between the two, the fixing method of the side wall and the through hole 1. The setting method of the sliding slider 30 is the same as that described above, and will not be repeated here.

[0051] The working process of the vacuum cleaner of the present invention is the same as that described above. When the dust in the dust collection bucket reaches a certain level, the dust collector is removed from the vacuum cleaner, and the push button at the bottom of the dust collection bucket above the garbage can is used to pass through the dust collector. The holes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com