Anti-corrosion method for the back of a single-sided polished wafer

A single-sided polishing and anti-corrosion technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to solve the problems of wafer 3 corrosion, single-sided polished wafer backside corrosion, and large investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

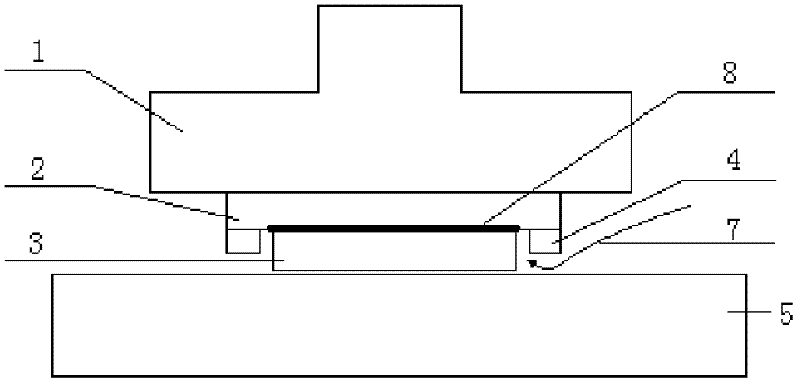

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0028] combine Figure 3 to Figure 11 As shown, it is the specific operation steps of the anti-corrosion method for the back side of the single-sided polished wafer in this embodiment. The method includes step S1: adding a reducing agent to the substrate 2, and the reducing agent is used to cover the wafer 3 before polishing and during the polishing process. to the back of the entire wafer 3 to prevent the chemical reaction between the polishing solution 7 and the back of the wafer 3 during the polishing process. The adsorption layer 8 is a solution layer when the wafer 3 is adsorbed during polishing, which is deionized water in conventional polishing operations, and in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com