Method for comprehensively utilizing supernatant of calcium carbide slurry and dilute brine generated by electrolysis

A technology of calcium carbide slurry and light brine, applied in the field of comprehensive utilization of environmental protection resources, can solve problems such as cost increase, environmental pollution, environmental impact, etc., and achieve the effects of saving cost, saving process water, and saving chlorine gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Wet acetylene production is to react calcium carbide with excess water. The resulting acetylene is processed and used for synthesis. After the reaction, the slurry is precipitated, cascaded, and stratified. The lower carbide slag can be used as building materials. Add alkali to the light brine after vacuum dechlorination to adjust the pH to 9-11, exchange heat with refined brine, and add clear liquid to react. Adjust the valve opening of the supernatant liquid pipeline so that the ORP is controlled below zero during the reaction process. In order to prevent sodium chlorate from corroding the pipeline, it is controlled below minus 200mV in the embodiment of the present invention, and is sent to the brine collection pool for the brine collection water.

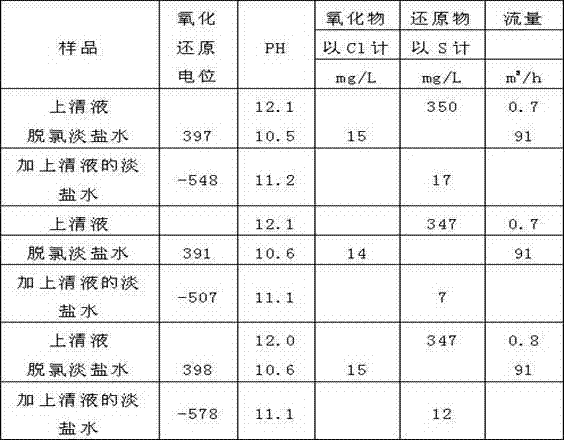

[0023] Application method: light brine and supernatant are respectively passed through the rotameter to adjust the flow rate and then enter the tubular reactor for reaction. The specific operating data is as follows:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com