Printing machine flash oven height synchronous adjustment mechanism

A technology for synchronous adjustment and printing machines, applied to printing machines, general parts of printing machinery, printing, etc., can solve the problems of small operating space, unreasonable force, poor moving stability, etc., and achieve the effect of smooth movement and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

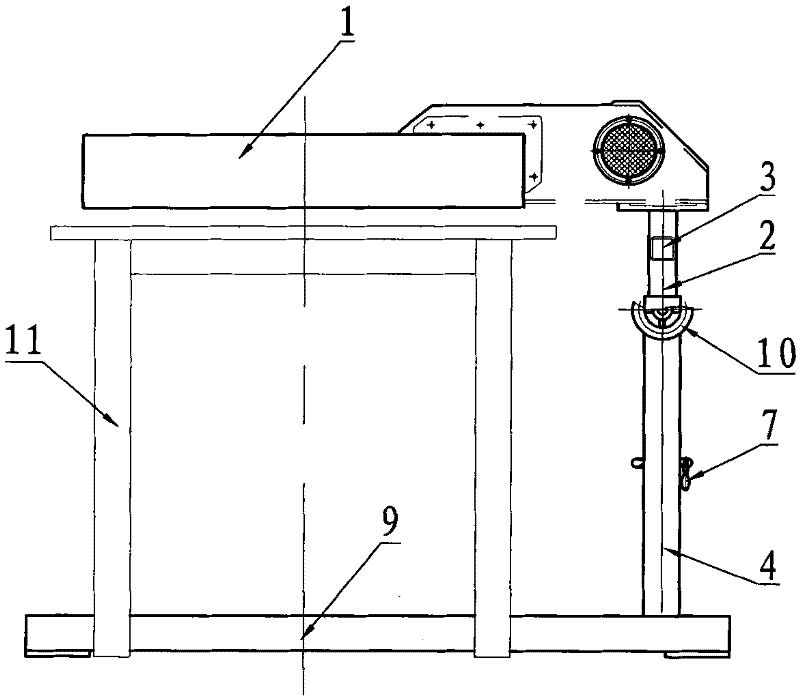

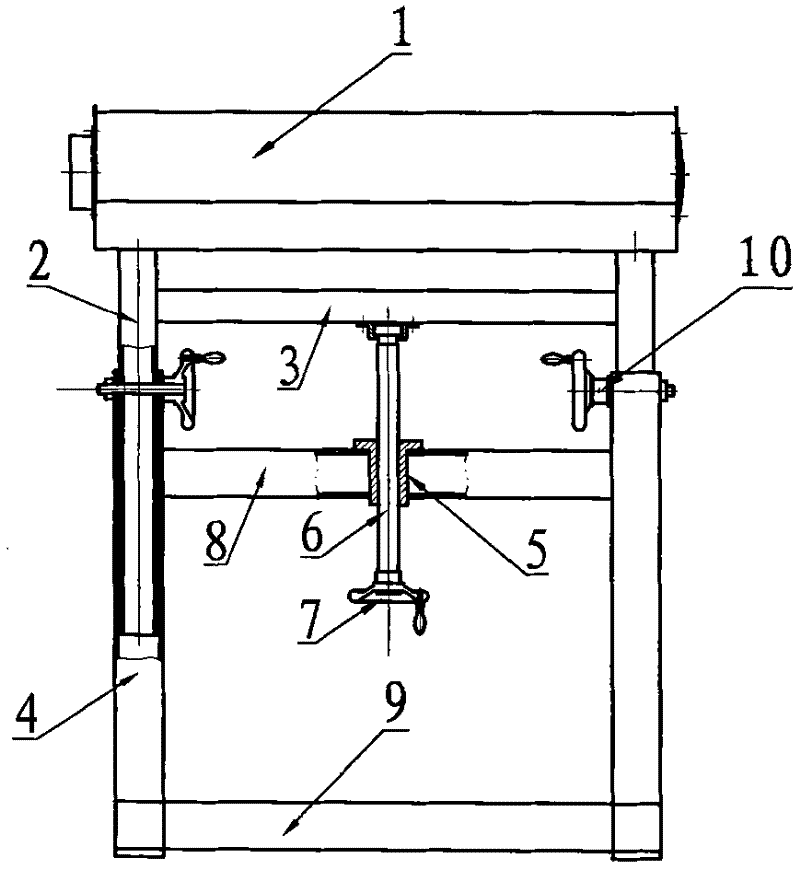

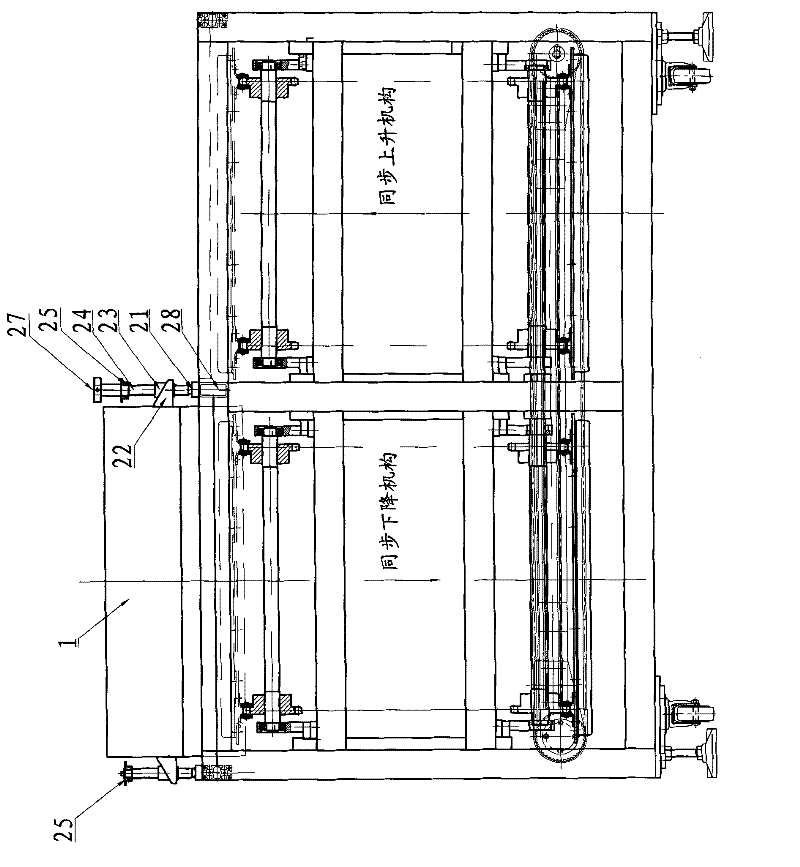

[0017] The printing machine flash oven height synchronous adjustment mechanism, such as Figure 3 ~ Figure 5 As shown, it includes frame 21, lug seat 22, threaded sleeve 23, screw rod 24, synchronous sprocket 25, chain 26, hand wheel 27 and flash oven 1, is provided with four lugs symmetrically on the left and right sides of flash oven 1 Seat 22, the center of the plane determined by the four ear seats 22 coincides with the center of gravity of the flash oven 1, four threaded sleeves 23 are fixed on the ear seats 22, and four screw rods 24 are screwed in the threaded sleeves 23 respectively. The upper end of 24 is fixedly installed a synchronous sprocket 25, and four synchronous sprockets 25 are in the same plane, and chain 26 is sleeved on the four synchronous sprockets 25, and the lower end of screw rod 24 is rotatably fixed on by limit seat 28. On the frame 21, a handwheel 27 is housed on a screw rod 24. Also be provided with tensioning sprocket 29 on frame 21, tensioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com