Cereal yoghurt and preparation method thereof

A technology of yogurt and cereals, applied in the direction of milk preparations, dairy products, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

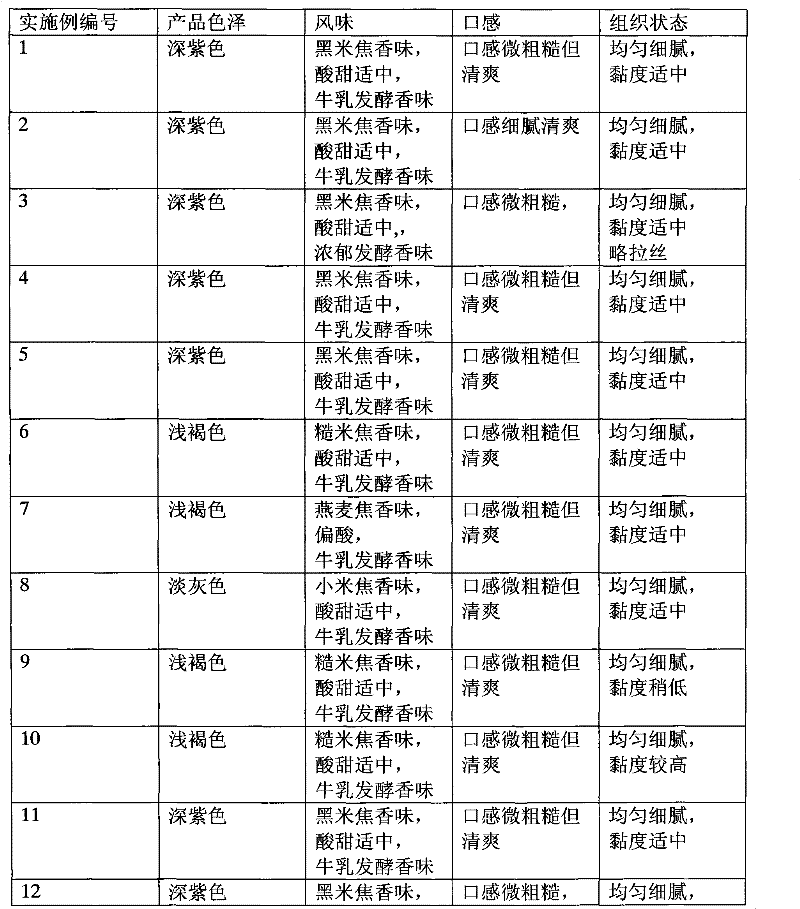

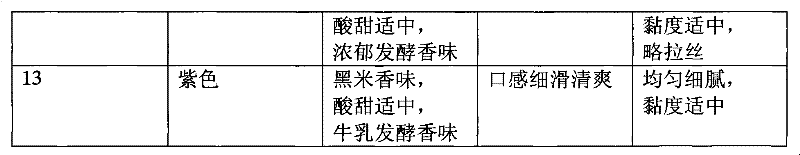

Examples

example 1

[0077] Homemade brown rice flour 75g, homemade black rice flour 75g, skimmed milk powder 10g, whey protein concentrate 10g, sugar 60g, fresh milk 560g, water 210g, mix all the above materials evenly, add amylase (the specific model is Validase BAA 1500L, from DSM Food Specialties B.V., Alexander Fleminglaan 1, 2613AX Delft, The Netherlands, the enzyme activity is 1500000MWU / g) 0.3g, and kept at 45-65 ° C for 30-60 minutes to stir and hydrolyze until the reducing sugar equivalent value of the mixture reaches more than 20, and then Heat the material to 65-70°C, homogenize at 200-220Bar; sterilize at 95°C for 5 minutes, cool to 43°C, add lactic acid bacteria starter (use direct injection type lactic acid bacteria starter, the model is DELVO-YOG SVV31DSL, from DSM FoodSpecialties B.V., Alexander Fleminglaan 1, 2613AX Delft, The Netherlands, which consists of Streptococcus thermophilus and Lactobacillus bulgaricus) 0.002-0.004U, mixed evenly, filled into packaging containers, and fe...

example 2

[0079] According to the mode of example 1, the difference is that the brown rice flour and black rice flour used are 200 mesh superfine powder purchased from Suntech Foods. The sensory evaluation results of the final product are shown in Table 1.

example 3

[0081] According to the mode of Example 1, the difference is that the lactic acid bacteria starter model used is DELVO-YOG MY1821DSL (derived from DSM Food Specialties B.V., Alexander Fleminglaan 1, 2613AX Delft, The Netherlands, which consists of Streptococcus thermophilus, Lactobacillus bulgaricus, Lactobacillus acidophilus, Bifidobacterium, Lactobacillus casei). The sensory evaluation results of the final product are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com