Waterproof self-heating floor system, and waterproof self-heating floors and self-heating assemblies thereof

A self-heating component, waterproof technology, applied in the field of architectural decoration, can solve problems such as unmentioned, burned floors, and unsolved waterproof problems of the floor system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

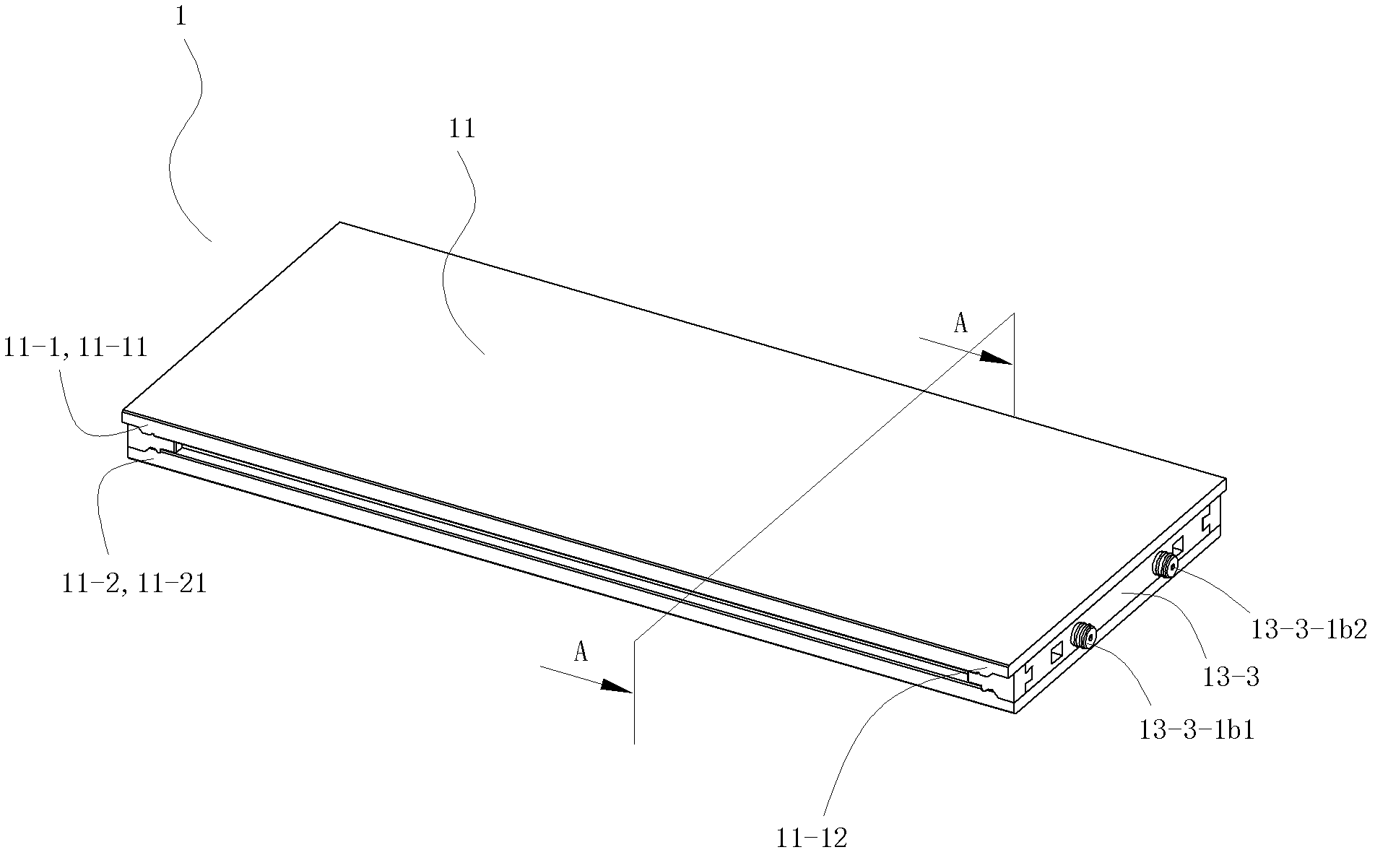

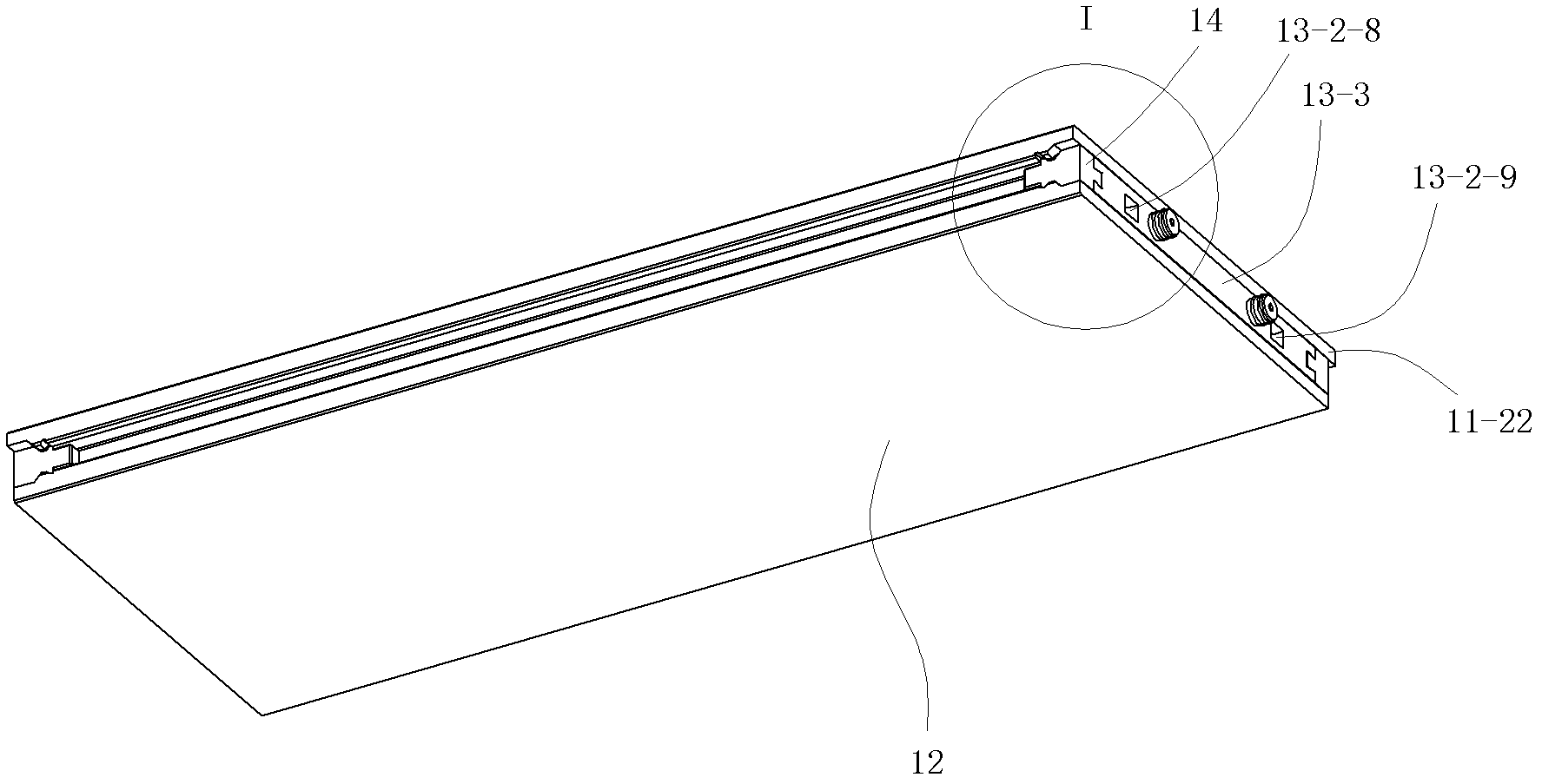

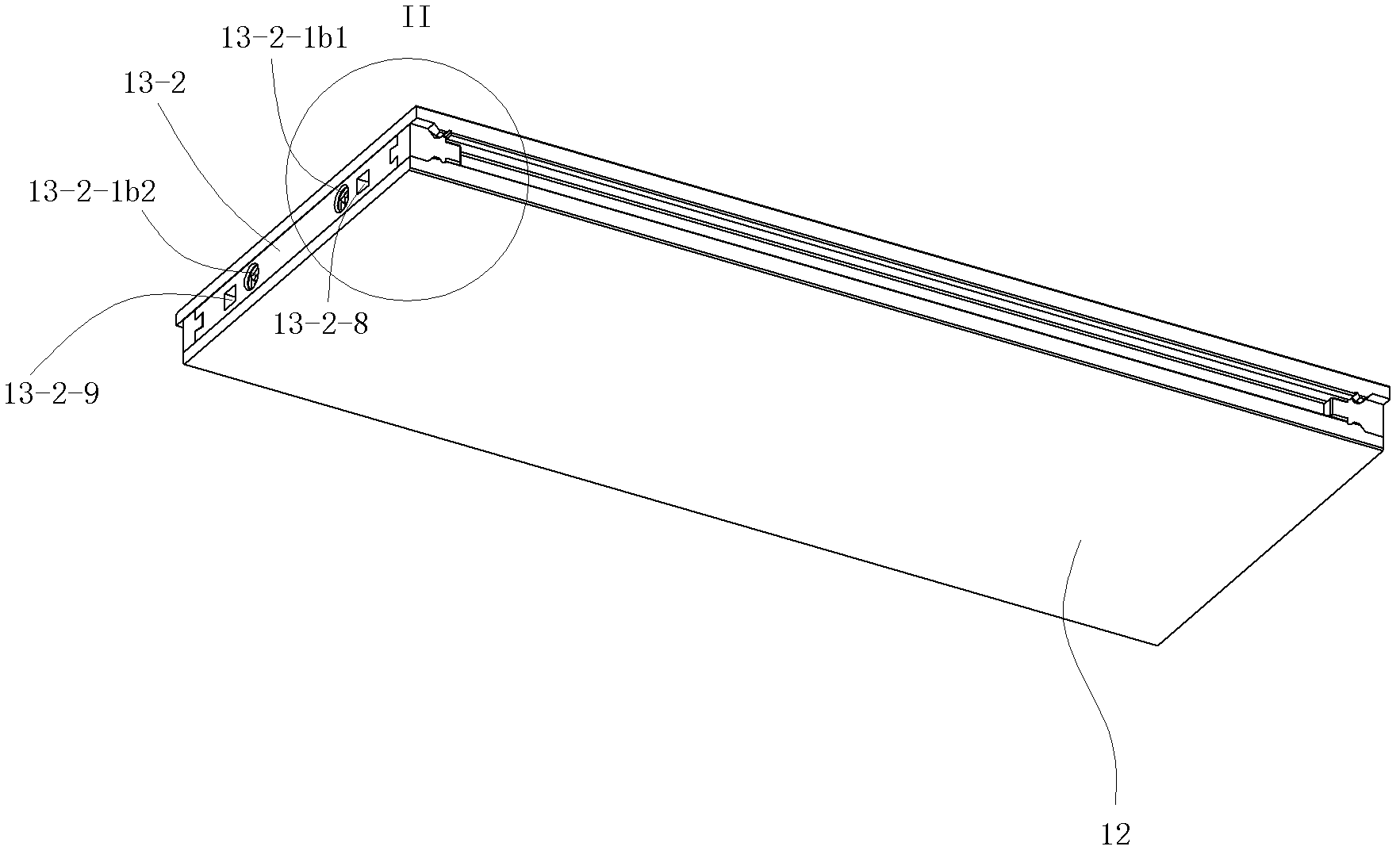

[0328] (Example 1, self-heating component)

[0329] See Figure 12 and Figure 13 The self-heating component 13 is a waterproof electric heating component, and the self-heating component 13 includes a transmission unit, a heating sheet 13-1, and socket parts 13-2 and double plug parts 13-3 respectively located at the left and right ends of the heating sheet 13-1. The transmission unit of the self-heating component 13 is composed of a waterproof live wire and a waterproof neutral wire, and the transmission unit of the self-heating component 13 includes two wires 13-4. The socket part 13-2 is a part that can be plugged and fixedly electrically connected with the double plug part 13-3 of the self-heating component 13 of the corresponding adjacent waterproof self-heating floor 1 during use, and is connected with each other in a sealed and waterproof connection; the double plug The part 13-3 is a part that can be plugged and fixedly connected with the double plug part 13-3 of the...

Embodiment 2

[0349] (Example 2, self-heating components)

[0350] See Figure 13 The rest of the self-heating assembly 13 of this embodiment is the same as that of Embodiment 1, except that the conductive copper sheet 13-2-2 at the live wire end is located at the left connecting section 13-1a of the front heating sheet 13-11 The front end of the front is electrically connected to the first copper member 13-2-3c, and the first copper member 13-2-3c is then electrically connected to the tail of the fire wire copper pin 13-2-3a, and the first copper member 13-2 -3c is electrically connected to the left end of the first electric wire 13-41 of the transmission unit by welding; the corresponding parts involved in the above structure constitute the first electrical connection component 13a1 on the socket side.

[0351] The tail end on the right side of the neutral line copper pin 13-2-3b is electrically connected to the second copper member 13-2-3d, and the second copper member 13-2-3d is then ...

Embodiment 3

[0354] (Example 3, self-heating components)

[0355] See Figure 26 to Figure 28 , the rest of the self-heating assembly 13 of the present embodiment is the same as that of Embodiment 1, the difference is that: the waterproof live wire and the waterproof zero wire of the transmission unit of the self-heating assembly 13 all include two conductive copper sheets 13-6 , aluminum foil 13-5 and polyvinyl chloride sheet 13-8. Each conductive copper skin 13-6 is fixed on the lower surface of the electric heater 13-1 from below, and the lower surface of each conductive copper skin 13-6 is coated with conductive glue. The shape of the aluminum foil 13-5 is the same as that of the strip-shaped conductive heating layer 13-1-1 of the electric heating sheet 13-1, and is located below the electric heating sheet 13-1, and covers the strip-shaped conductive heating layer 13-1-1 from below. 1, and the upper surfaces of the left and right ends of the aluminum foil 13-5 are electrically conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com