Direct current driving numerical control device for high-power IGBT (Insulated Gate Bipolar Translator) rectification circuit

A technology of rectifier circuit and numerical control device, which is applied in the direction of DC motor speed/torque control, reactive power adjustment/elimination/compensation, harmonic reduction device, etc. Cost and other issues, to achieve the effect of improving service life, improving power factor, and reducing harmonic generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

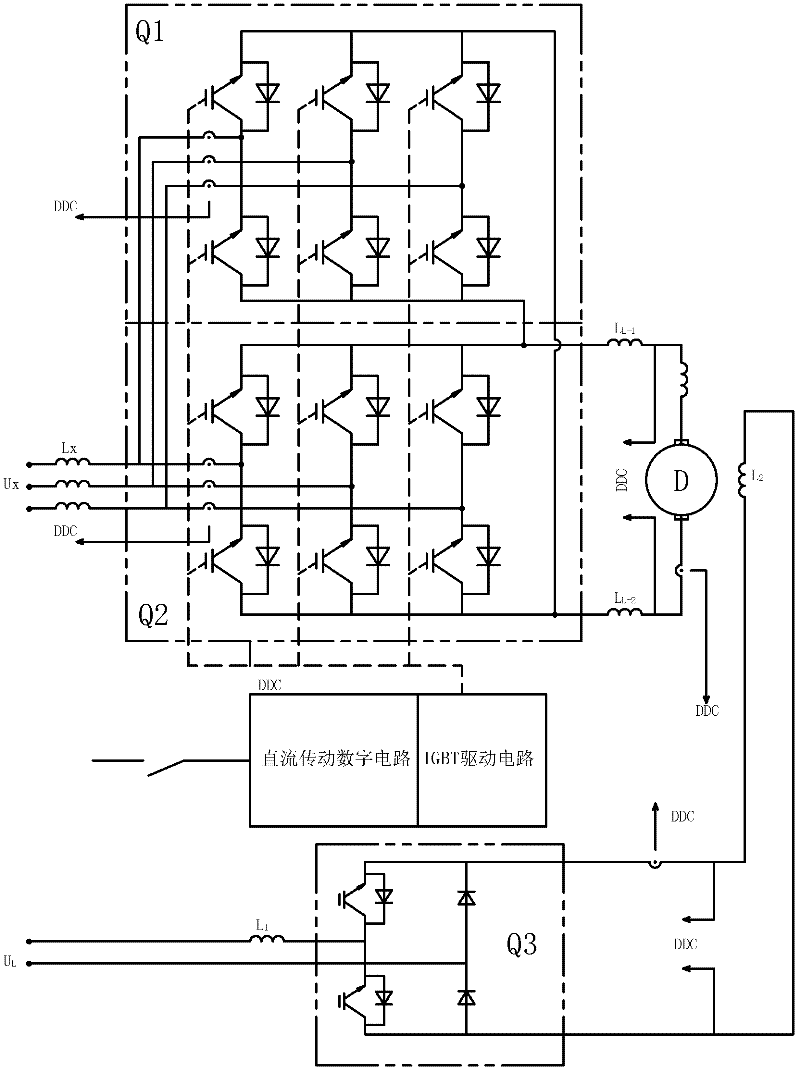

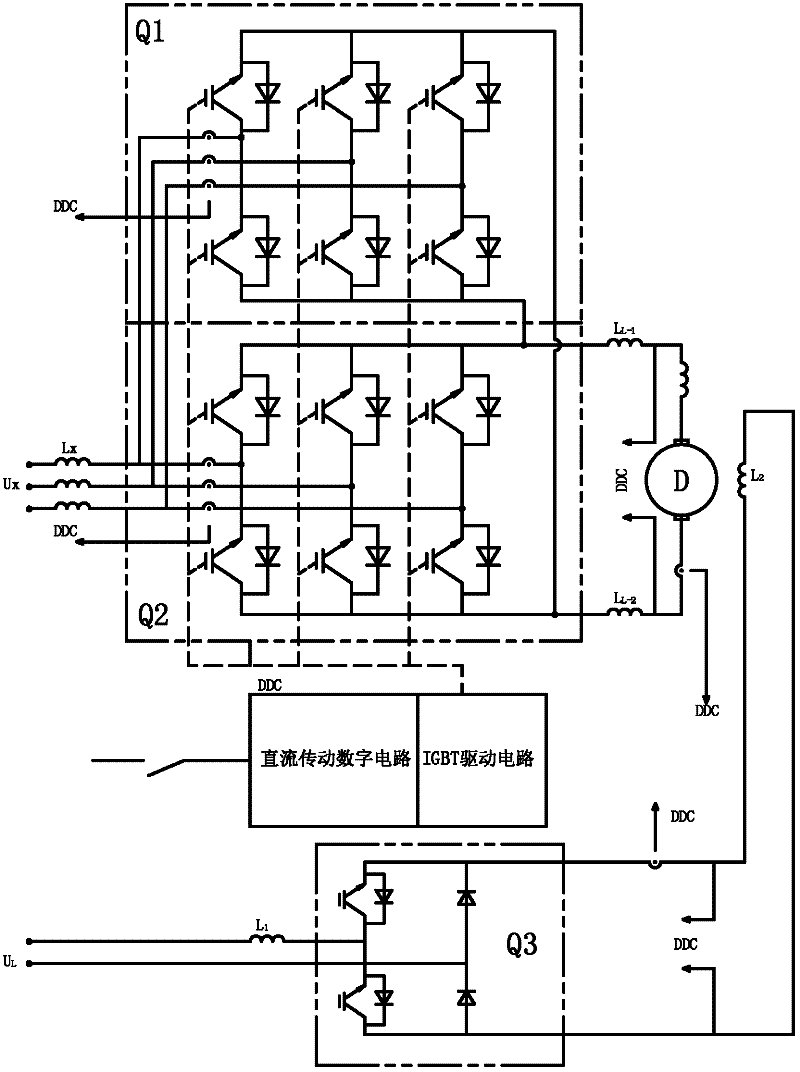

[0013] See figure 1 , a high-power IGBT rectifier circuit DC drive numerical control device, including two sets of three-phase rectifier bridges Q1 and Q2 composed of IGBT devices and diodes. Filter reactor L L-1 , L L-2 Connect with DC motor D. Buffer reactor Lx and filter reactor L L-1 , L L-2 Both play the role of harmonic filtering.

[0014] When the two groups of the device work at the same time, it is a four-quadrant energy feedback structure, one group is in the rectification working state, and the other is in the inverter working state; when the DC motor D is started, it is in the rectification state of AC to DC; in the DC motor D When braking, the device is in the inverter state, inverting DC to AC, and feeding energy back to the grid.

[0015] When one group of the device is working, it is a two-quadrant rectification structure, and the energy is transmitted to the DC motor D by the grid.

[0016] Each three-phase rectifier bridge is composed of six IGBT devic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap