Silicon micro angular vibration output gyroscope

A technology of gyroscope and angular vibration, which is applied in directions such as steering sensing equipment, can solve problems such as the difficulty of processing vertical torsion bars, and achieve the effects of improving sensitivity and stability, reducing difficulty, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

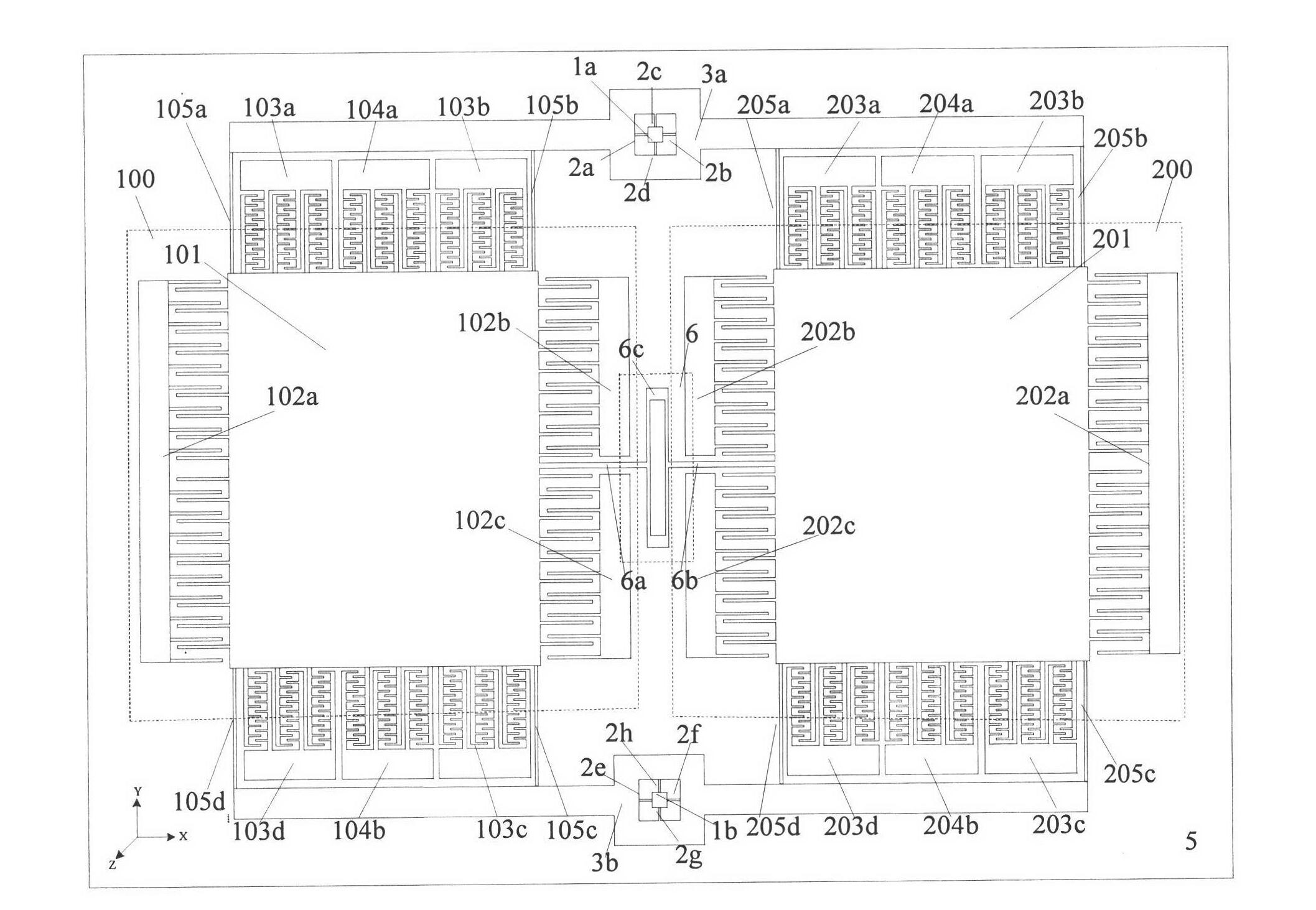

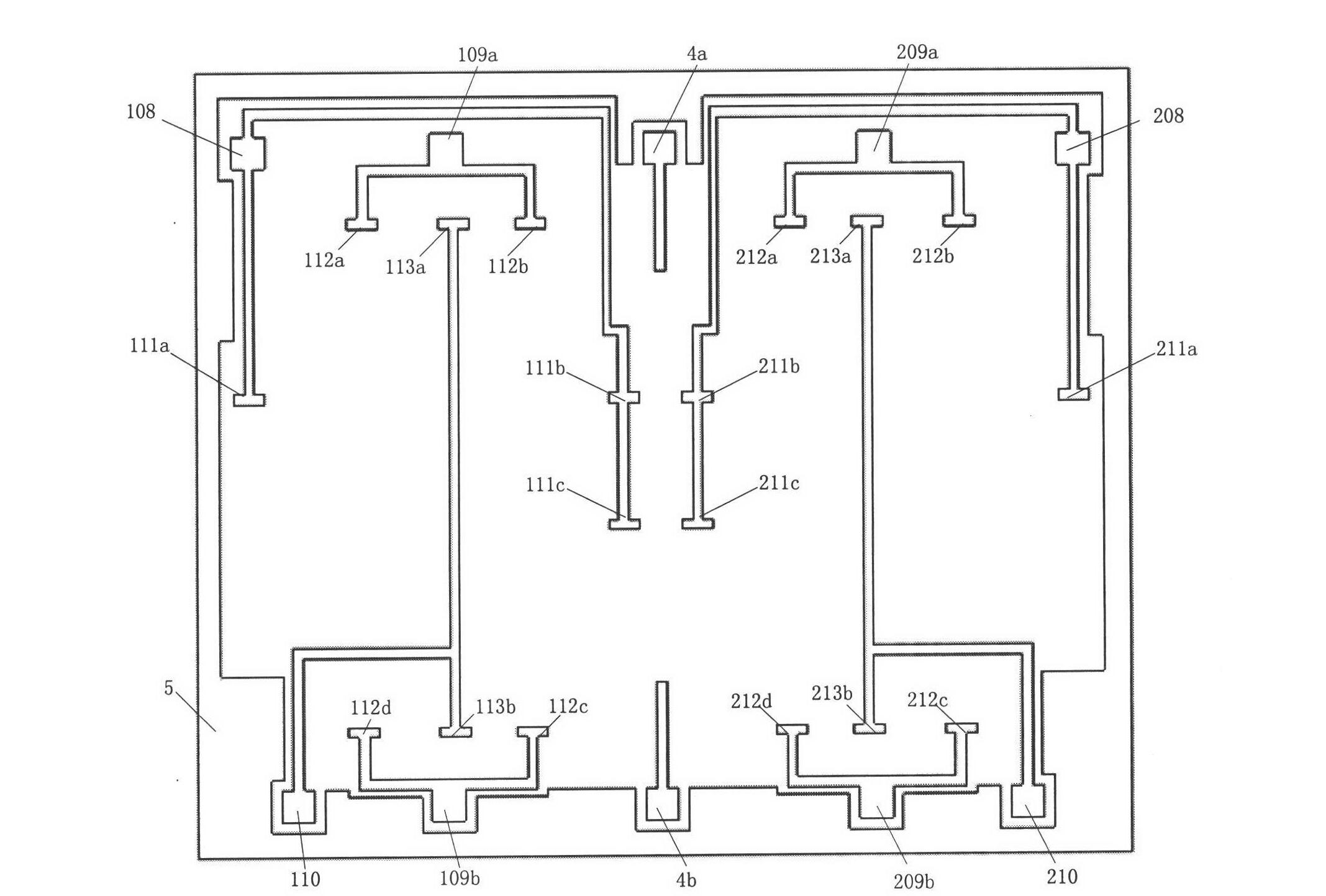

[0012] combine figure 1 , the silicon micro-angular vibration output gyroscope of the present invention is used to measure the angular rate in the Z-axis direction. The gyroscope consists of an upper mechanical structure and a lower glass substrate. The upper mechanical structure of the gyroscope is composed of a pair of identical substructures 100, 200. The two substructures 100, 200 are symmetrically arranged left and right, and are connected to each other through the mass connection mechanism 6. At the same time, the two substructures 100, 200 are connected to the beam 3a , 3b connection. The first beam 3a is connected to the first fixed base 1a through the first group of horizontal torsion bars 2a, 2b, 2c, 2d. The second beam 3b is connected to the second fixed base 1b through a second group of horizontal torsion bars 2e, 2f, 2g, 2h. The mass connection mechanism 6 is composed of two connecting rods 6a, 6b and a connecting frame 6c. One end of the two connecting rods 6a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com