Oil baffle assembly and rotary compressor with same

An assembly and oil baffle technology, which is applied in the field of compressors, can solve the problems of reducing the heat exchange performance of the air conditioning system, reducing the energy efficiency of the air conditioner, and reducing the reliability of the compressor, thereby simplifying the structure, reducing the oil output, and improving the reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

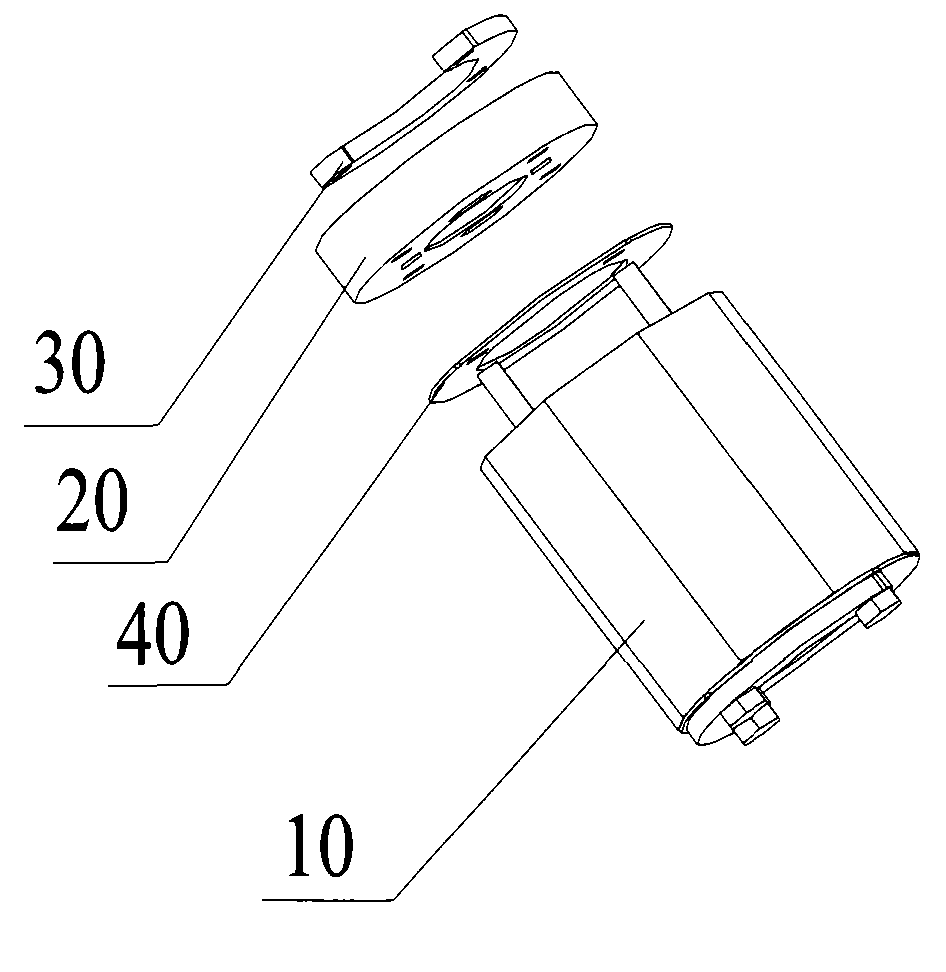

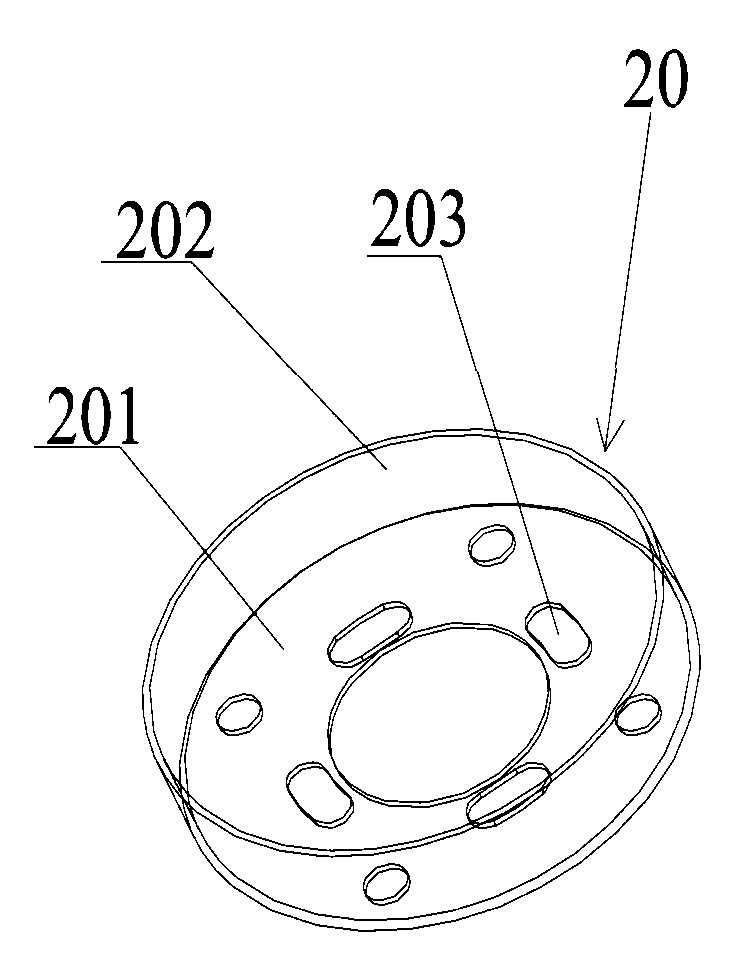

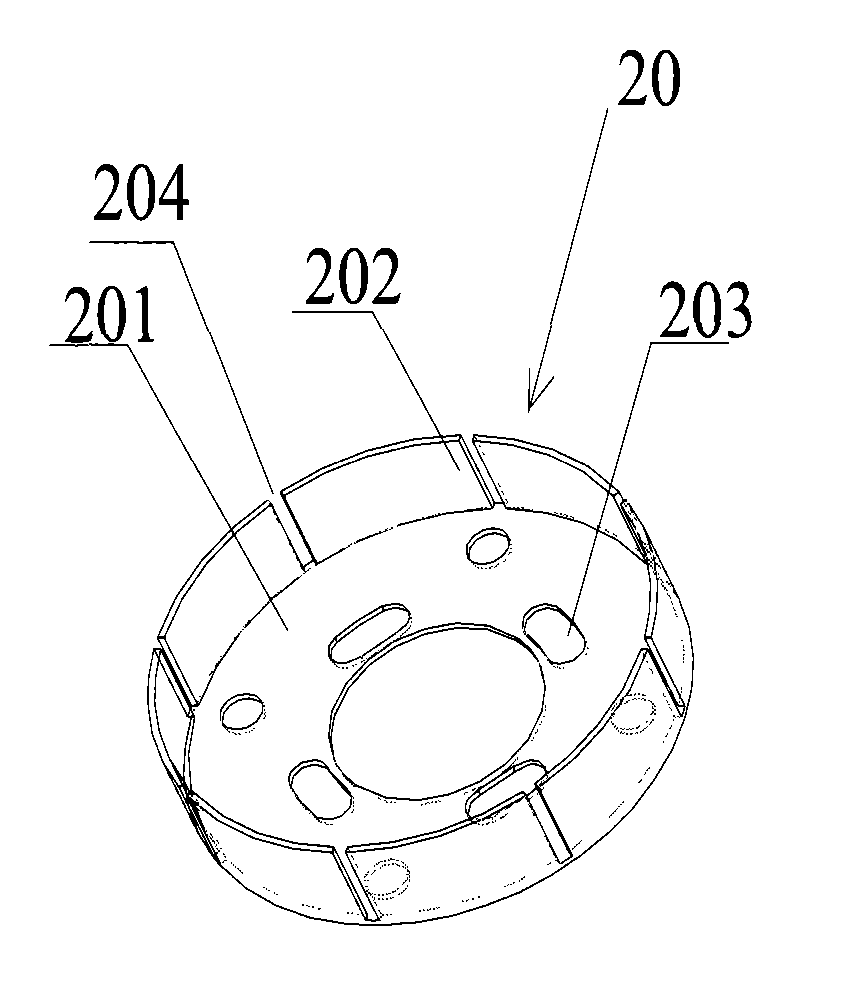

[0021] figure 1 It is a structural diagram of an embodiment of the oil retaining assembly according to the present invention, combined with reference to Figure 1-Figure 3 , as shown in the figure, the present invention provides an oil baffle assembly, including: a rotor 10; an oil baffle 20 connected to the rotor 10, the oil baffle 20 includes a bottom plate 201 and a side plate 202 surrounding the bottom plate 20, The bottom plate 201 has a plurality of through holes 203 . The use of the bottom plate 201 of the oil baffle 20 can replace the baffle installed on the upper end surface of the rotor in the prior art, and simplify the structure of the compressor. The oil baffle assembly can effectively control the refrigerating oil in the compressor through the oil baffle, prevent the refrigerating oil from leaking out, greatly reduce the oil discharge volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com