Differential adjustable unilateral expansion nozzle

A single-side expansion nozzle and differential technology, which is applied in the direction of machines/engines, jet propulsion devices, etc., can solve the problem of high thermal load of the nozzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

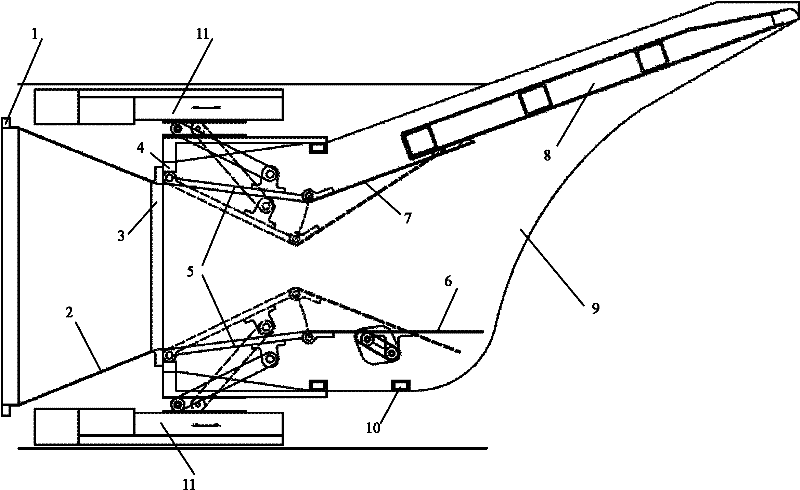

[0020] The nozzle scheme diagram according to an embodiment of the present invention is shown in figure 1 , the nozzle includes a front mounting edge (1), a circular torque transition section (2), a rear mounting edge (3), a rotating piece fixing casing (4), an upper / lower convergence adjustment plate (5), a lower web ( 6), adjustable upper web (7), fixed upper web (8), left / right side panels (9), support beams (10) and stepping motors (11), etc.

[0021] Actuation system

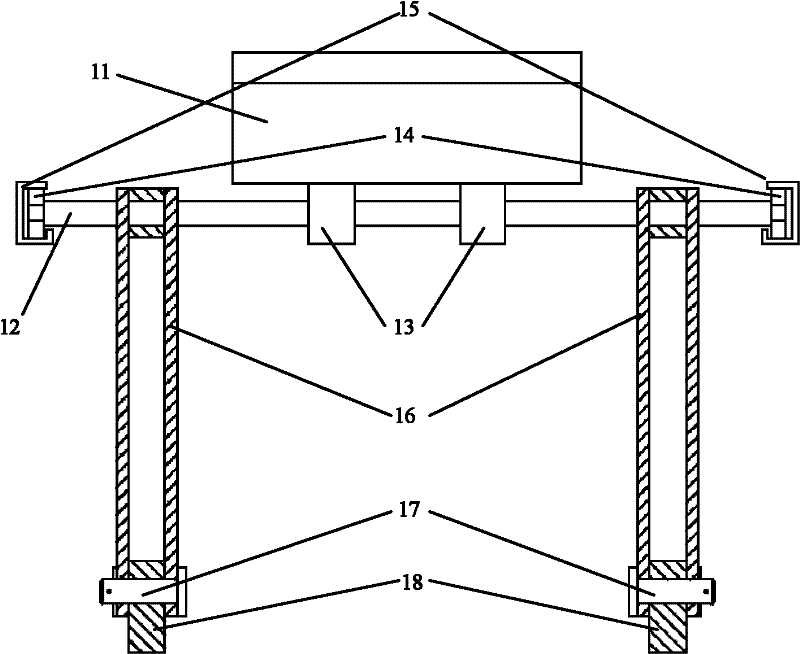

[0022] Such as figure 2 As shown, the actuation system according to one embodiment of the present invention includes a stepper motor (11), a stepped shaft (12), a mounting seat (13), a miniature bearing (14), a fixed channel (15) and a double-ended pull rod (16), wherein the stepper motor (11) transmits the axial displacement to the stepped shaft (12) through the mounting seat (13) connected thereto, and the stepped shaft (12) drives the miniature bearing (14) while doing axial movement Roll on fixed ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com