Preparation method of high whiteness and high density polyethylene

A technology of high-density polyethylene and high whiteness, which is applied in the field of preparation of high-whiteness high-density polyethylene, and can solve problems such as the difficulty of applying high-density polyethylene products and the limitation of whiteness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention provides a kind of preparation method of high whiteness high density polyethylene and the prepared high whiteness high density polyethylene thereof, described method comprises the following steps:

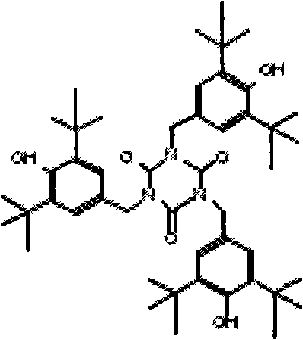

[0047] Described antioxidant comprises main antioxidant and auxiliary antioxidant, and wherein main antioxidant is 1,3,5-three (3,5-di-tert-butyl-4-hydroxybenzyl) isocyanuric acid, molecular formula For: C 48 h 69 N 3 o 6 , the structural formula is:

[0048]

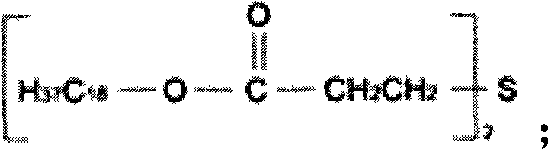

[0049] The auxiliary antioxidant is dioctadecyl thiodipropionate, and its molecular formula is: C 42 h 82 o 4 S, the structural formula is:

[0050]

[0051] The processing aid is zinc calcium stearate processing aid, and the weight ratio of zinc stearate and calcium stearate in the processing aid is 1: 0.95~1: 1.05;

[0052] The metal ion deactivator is a polyhydric alcohol metal ion deactivator.

[0053] antioxidant

[0054] Described antioxidant comprises main antioxidant and a...

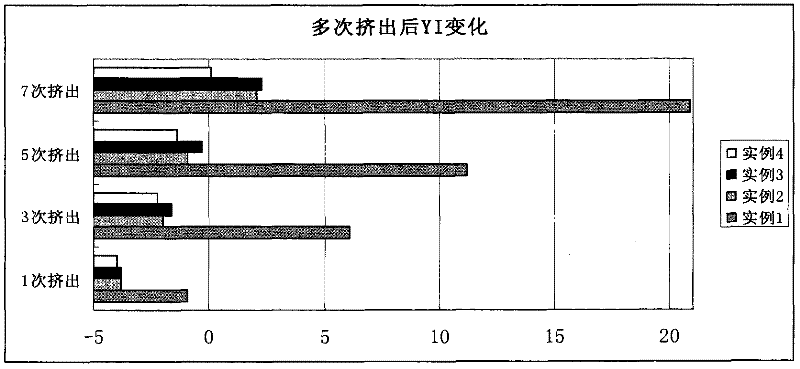

Embodiment

[0094]By using auxiliary antioxidant DSTDP containing 300ppm main antioxidant Irganox3114, 500ppm, 1000ppm zinc calcium stearate processing aid (the ratio of zinc calcium is 1: 1), 50ppm metal ion deactivator glycerol and 5ppm fluorescent whitening Antioxidant premixing system of agent OB, select high-speed co-rotating meshing twin-screw extruder, control the processing temperature of twin-screw extrusion at 210°C, screw speed at 300rpm / min, chromium-based high-density polyethylene products It has the best initial color; when the feeding speed is controlled at 0.75Hz, the system has the best color stability after several compound extrusions, and the color retention ability has been greatly improved.

[0095] According to the ISO1133 method, under the conditions of temperature 190°C and pressure 21.6Kg, the measured melt flow rate is 5-16.0g / 10min, the recommended melt flow rate is 8-11g / 10min, and the recommended density is 949-953kg / m3.

[0096] The above-prepared polyethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com