Waste water recycling device for paper making vacuum system and water saving method

A waste water recovery and vacuum system technology, which is applied in the direction of processing waste water treatment, degassed water/sewage treatment, etc., can solve the problems of increased energy consumption in the recovery system, easy generation of sediment and dirt, and rise in temperature of the working fluid, so as to reduce energy consumption. consumption, stable load, and stable vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

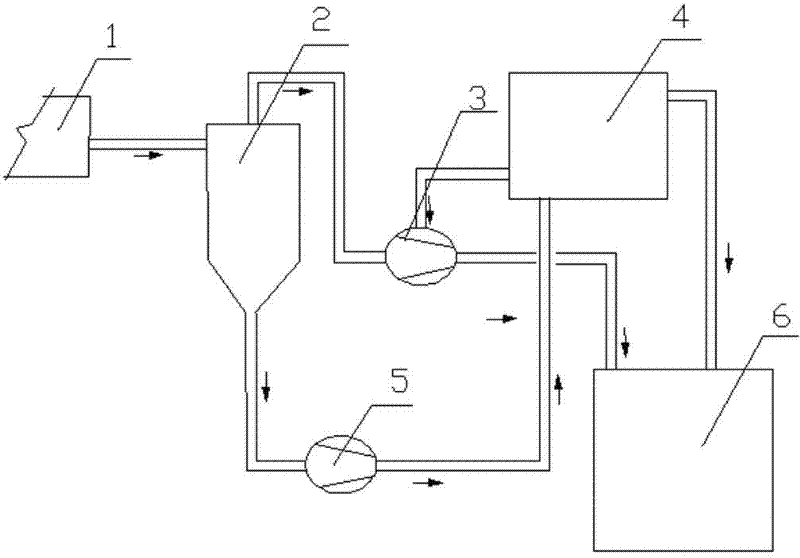

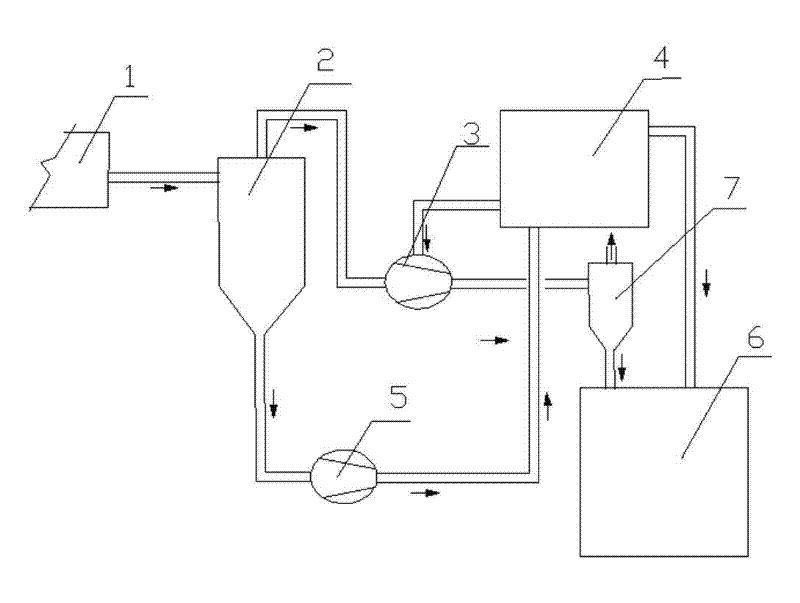

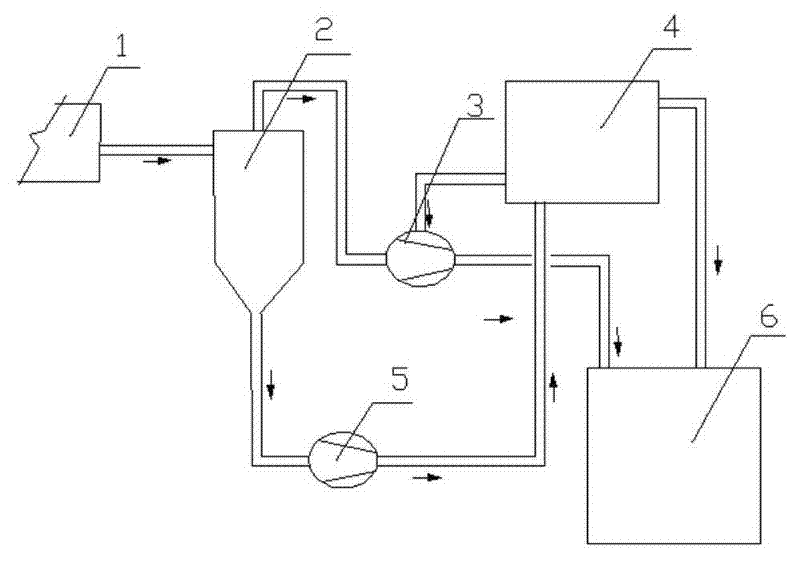

[0014] figure 1 It is a structural schematic diagram of the paper machine wastewater recycling device of the present invention. The paper machine wastewater recycling device includes a vacuum dehydration element 1, an air-water separator 2, a vacuum pump 3, a high-level tank 4, a negative pump 5, a white water pool 6, pipelines, etc., and the air-water separator 2 includes a cylinder, an There is a gas-liquid inlet on one side of the upper part of the body, an air outlet on the top of the cylinder, and a pumping port on the bottom of the cylinder. The gas-liquid inlet is connected to the vacuum dehydration element 1 through a pipeline, and the air outlet is connected to The inlet of the vacuum pump 3 is connected, the discharge outlet 3 of the vacuum pump is connected with the white water pool 6 through a pipeline, the exhaust port of the vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com