Trichlorosilane vaporizing process

A technology of trichlorosilane and high-purity trichlorosilane, applied in silicon compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of ratio fluctuation, affecting product quality, uneven mixing, etc., to avoid liquid foam Entrainment, good appearance quality, uniform mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

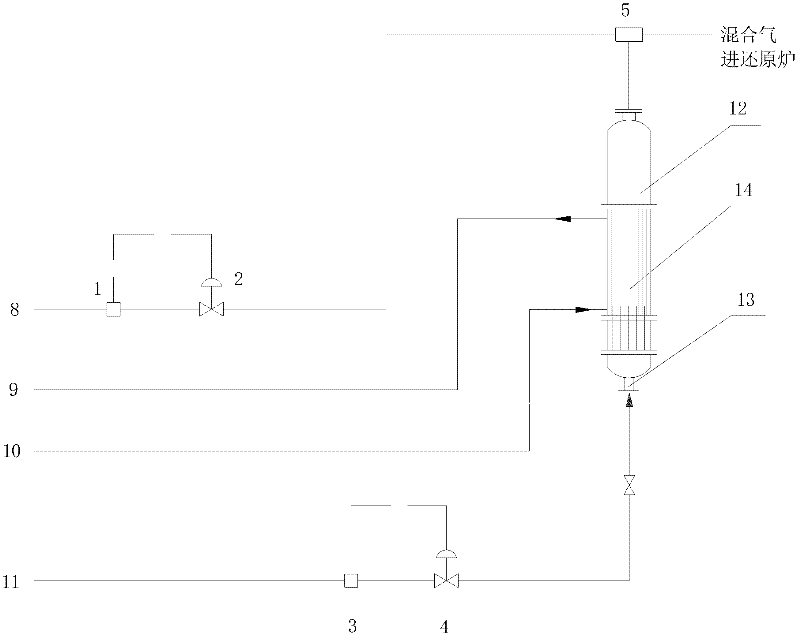

[0039] The trichlorosilane vaporization process enumerated in this embodiment includes the following steps:

[0040] (1) The high-purity trichlorosilane liquid obtained by rectification is measured by the trichlorosilane mass flowmeter 3 and the trichlorosilane flow regulating valve 4, and the adjusted flow rate is 20kmol / h. The trichlorosilane liquid inlet 13 is fed into the tube side of the tube-and-tube heat exchanger 14 of the evaporator 12, the pressure of the evaporator is about 0.5MPa, and the temperature is about 65°C;

[0041] The evaporator 12 provides the heat energy required for the evaporation of trichlorosilane by the external circulating water of the tube side. The external circulating water 10 is the cooling water of the polysilicon reduction furnace barrel, the temperature is 150°C, and the circulation rate is 10000kg / h , the outlet water temperature is 142℃, which can effectively utilize the heat energy of the polysilicon reduction furnace;

[0042] (2) Tric...

Embodiment 2

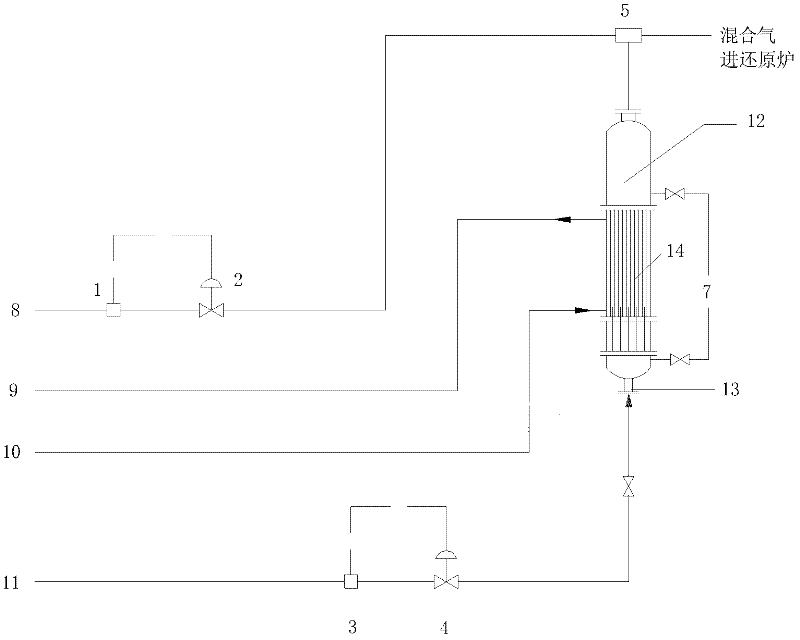

[0048] The trichlorosilane vaporization process enumerated in this embodiment includes the following steps:

[0049] (1) The high-purity trichlorosilane liquid obtained by rectification is measured by the trichlorosilane mass flowmeter 3 and the trichlorosilane flow regulating valve 4, and the adjusted flow rate is 20kmol / h. The trichlorosilane liquid inlet 13 is fed into the tube side of the tube-and-tube heat exchanger 14 in the evaporator 12, the pressure of the evaporator is about 0.7MPa, and the temperature is about 55°C;

[0050] The evaporator 12 provides the heat energy required for the evaporation of trichlorosilane by the external circulating water of the tube side. The external circulating water 10 is the cooling water of the polysilicon reduction furnace barrel, the temperature is 150°C, and the circulation rate is 10000kg / h , the outlet water temperature is 140℃, which can effectively utilize the heat energy of the polysilicon reduction furnace;

[0051] The tube...

Embodiment 3

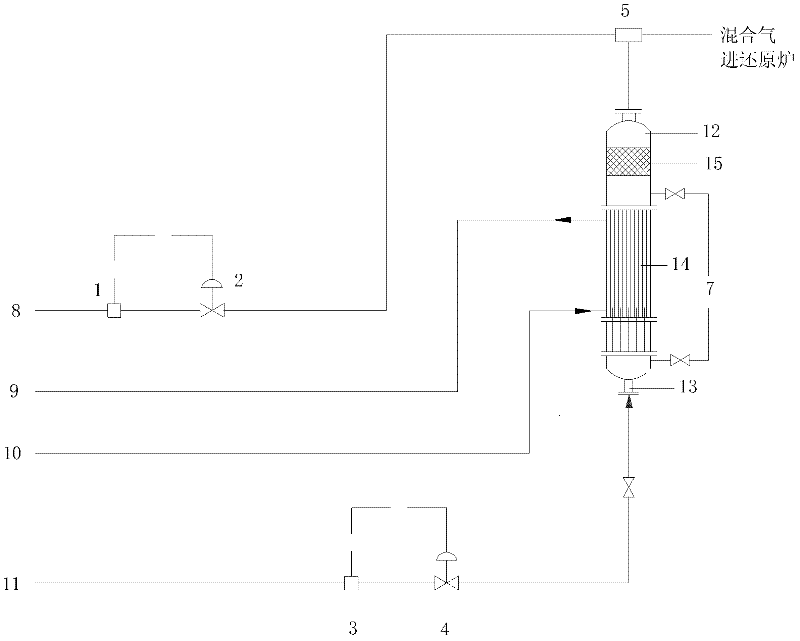

[0058] The trichlorosilane vaporization process enumerated in this embodiment includes the following steps:

[0059] (1) The high-purity trichlorosilane liquid obtained by rectification is measured by the trichlorosilane mass flowmeter 3 and the trichlorosilane flow regulating valve 4, and the adjusted flow rate is 20kmol / h. The trichlorosilane liquid inlet 13 is fed into the evaporator 12, and the evaporator 12 includes a lower shell-and-tube heat exchanger 14 and an upper demister 15;

[0060] The shell-and-tube heat exchanger 14 is provided with the heat energy required for the evaporation of trichlorosilane by the external circulating water of the shell-and-tube tube side. It is 10000kg / h, and the outlet water temperature is 140℃, which can effectively utilize the heat energy of the polysilicon reduction furnace;

[0061] The tube side of the tubular heat exchanger 14 is connected with a liquid level gauge 7, which can more accurately control the constant level of trichlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com