Double-way molded coal molding machine and molding method thereof

A technology of forming machine and briquette, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems that the briquette does not meet the requirements of industrial briquette, and the forming quality is poor, and achieves the moment-inertia ratio. Large size, good molding quality, and the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

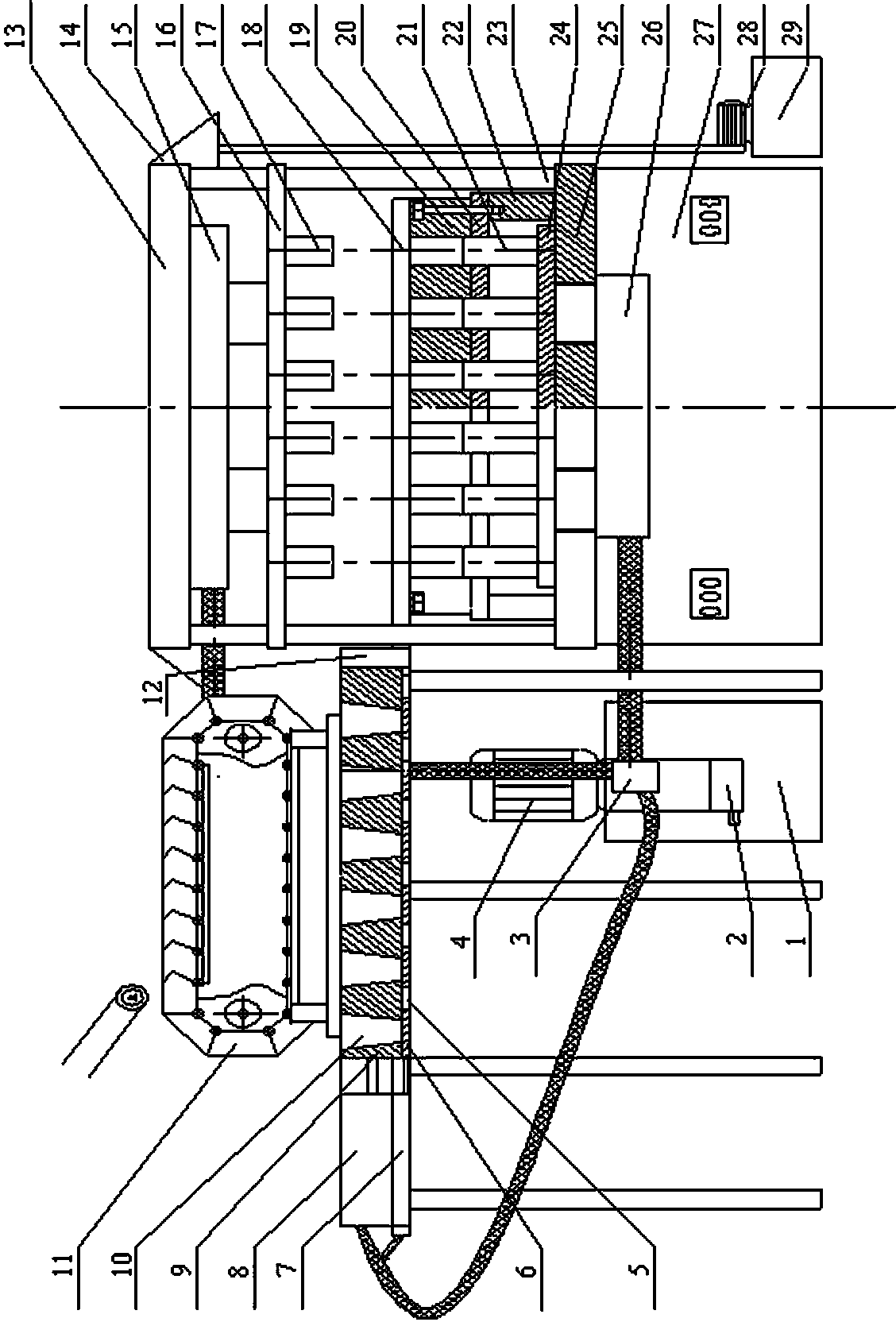

[0022] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

[0023] The present invention provides a two-way briquette forming machine to improve the defects of poor block forming quality in existing briquette forming machines, which are mainly manifested in uneven block forming and high forming damage rate. Because the briquette forming machine is outdated and backward, the production efficiency is low, the labor intensity is high and the dust pollution is serious. On this basis, the present invention combines the characteristics of coal powder, powder, binder and spheroidizing agent mixture feeding, through stamping and vibration forming and many other experimental studies, on the basis of comprehensive consideration of production capacity, efficiency and investment factors On the basis of this, a technical scheme of a two-way briquette forming machine has been designed.

[0024] The technical schem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com