Hydrogen-trapping material, method of preparation and uses

A technology of radioactive materials and hydrogen absorbing agents, applied in chemical instruments and methods, hydrogen, hydrogen separation, etc., can solve problems that have not been raised and are not sensitive to radiation decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

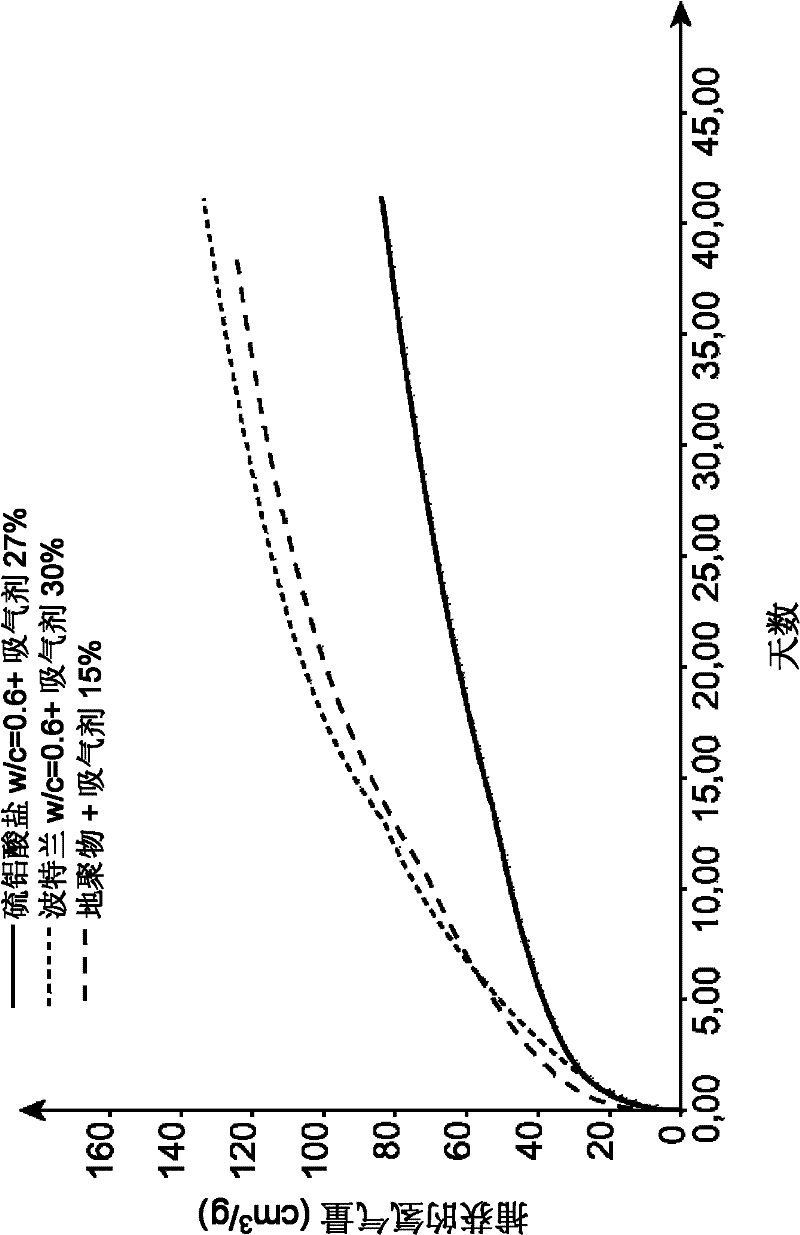

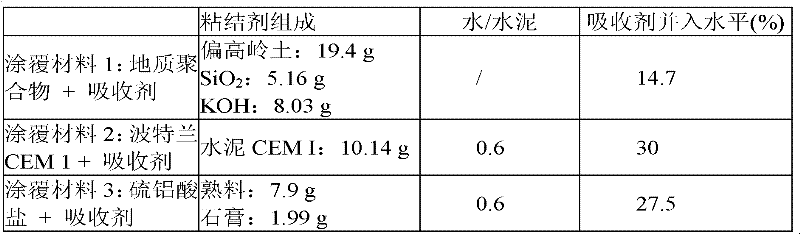

[0083] 1. Preparation of coated cement with hydrogen absorbing agent

[0084] The metal oxide used to prepare the hydrogen absorber is activated MnO 2 (Merck, >90%) and Ag 2O (Merck, >99%). The two compounds were mixed mechanically and water was added to the mixture, then the whole was dried in an oven for 2 hours [16].

[0085] Cement / hydrogen absorber coating materials were prepared from different binders. The three binders used to prepare coating materials with hydrogen absorbers are as follows:

[0086] - Geopolymer (No. 1 Coating Material)

[0087] - Portland Cement CEM I (Coating Material No. 2)

[0088] -Sulphoaluminate (coating material No. 3)

[0089] Products used for geopolymers are Metakaolin (Grade Construction Product), KOH (Prolabo, 98%) and SiO from Pieri Premix MK 2 (Tixosil, Degussa).

[0090] Portland / Absorbent and Sulphoaluminate / Absorbent were prepared using CEM Type I 52.5N cement (Lafarge Le Teil) with an 80 / 20 (by weight) mixture of clinker (y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com