Hybrid power generation system and using method thereof

A hybrid power generation and thermoelectric power generation module technology, applied in the field of solar power generation, can solve the problems of insufficient utilization of solar energy resources, low photoelectric conversion efficiency, unsatisfactory photoelectric conversion efficiency, etc., to achieve high output voltage and output power, and improve utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

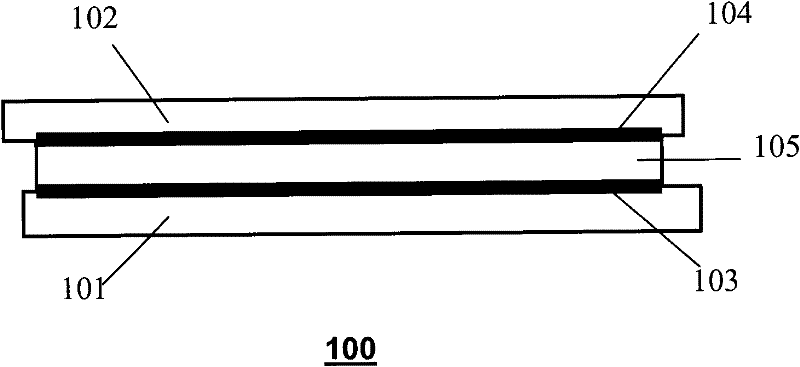

[0027] Figure 2a It is a hybrid power generation system according to an embodiment of the present invention, and the system includes a sensitized solar cell 100 , a semiconductor thermoelectric power generation module 200 and a heat dissipation module 300 . Figure 2b Schematic diagram of the structure of a sensitized solar cell. Such as Figure 2b As shown, the sensitized solar cell 100 is composed of a photoanode, an electrolyte and a counter electrode, wherein the photoanode is a porous TiO prepared on a substrate 101 such as a titanium sheet or a titanium foil 2 The film 103 has ruthenium dye attached to its surface as a sensitizer; the counter electrode is a catalytic layer 104 such as pyrolytic platinum covered on a substrate 102 such as transparent conductive glass or transparent conductive plastic; the electrolyte 105 is a quasi-solid or solid electrolyte. Such as Figure 2a As shown, between the hot end of the sensitized solar cell 100 and the semiconductor thermo...

Embodiment 2

[0034] In the hybrid power generation system of Example 2, the photoanode substrate of the dye-sensitized solar cell is a porous ZnO film prepared on transparent conductive glass or transparent conductive plastic, the sensitizer on it is an organic dye, and the substrate of the opposite electrode is a coated Polypyrrolate on graphite or metal conductive materials, the electrolyte is a quasi-solid or solid electrolyte. The hot end of the thermoelectric power generation module is directly bonded to the back of the counter electrode substrate of the sensitized solar cell, and the cold end of the thermoelectric power generation module is closely bonded to the aluminum air-cooled heat sink through thermal conductive silica gel. The usage method of this hybrid power generation system is the same as that of Embodiment 1.

Embodiment 3

[0036] In the hybrid power generation system of Example 3, the photoanode and the counter electrode substrate of the dye-sensitized solar cell are the same, both are transparent conductive glass or transparent conductive plastic, and the photoanode is porous TiO 2thin film, the sensitizer is ruthenium dye, the electrolyte is liquid or ionic liquid electrolyte, and the counter electrode is pyrolytic platinum. The hot end of the thermoelectric power generation module is directly bonded to the back of the counter electrode substrate of the sensitized solar cell, and the cold end insulation heat conduction plate of the thermoelectric power generation module is closely bonded to the aluminum air-cooled heat sink through thermal silica gel. The usage method of this hybrid power generation system is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com