Automatic fuse threading machine for tubular fuse holder

A technology of fuse and automatic threading, applied in the field of wire threading machines, can solve the problems of missing insertion or multi-insertion, consuming a lot of manpower, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

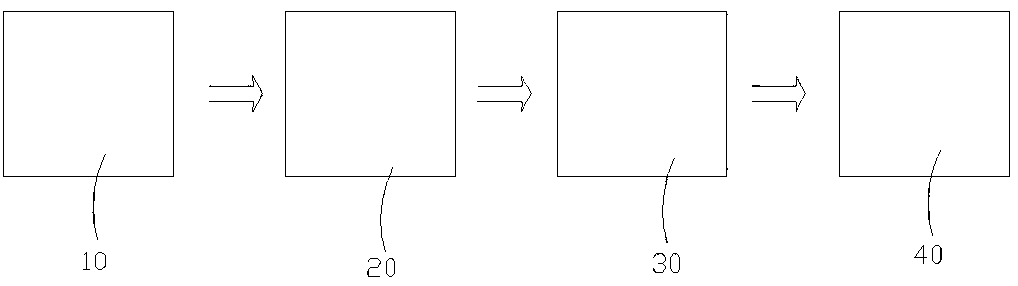

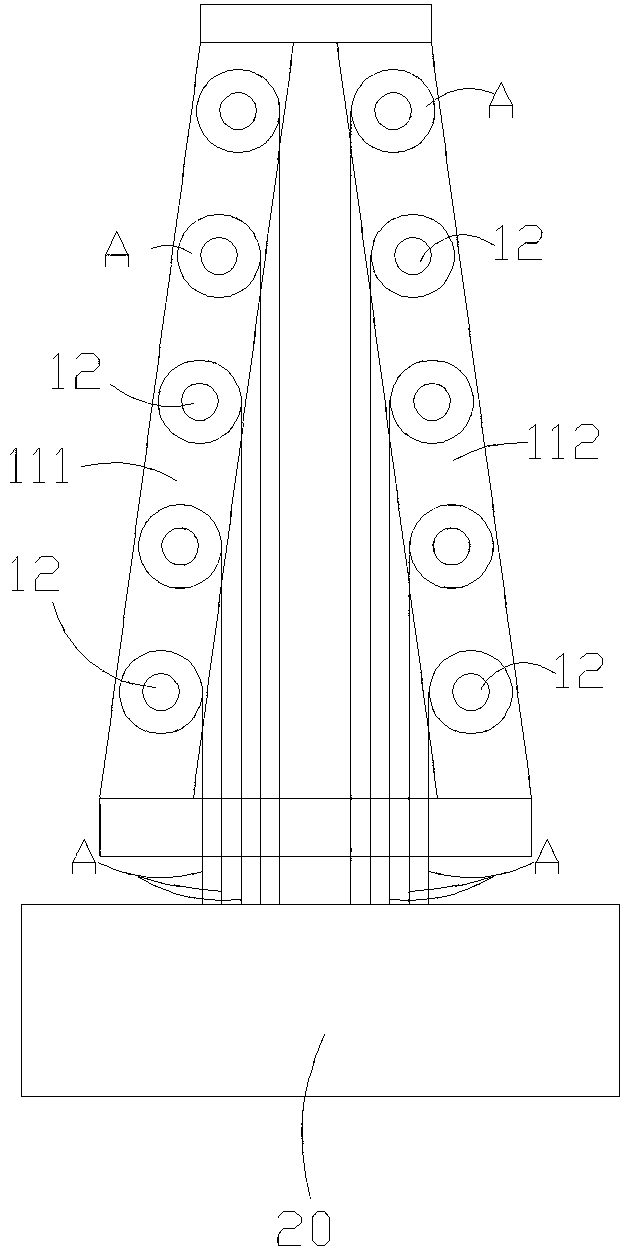

[0033] Such as Figures 1 to 9 As shown, an automatic wire threading machine for a tubular fuse includes a wire feeding unit 10 , a wire drawing unit 20 , a power unit 30 and a cutting unit 40 .

[0034] Such as Figure 9 As shown, the fuse automatic wire threading machine of the present invention adopts numerical control automation as a whole to work, and the fuses A waiting to be threaded into the fuse are wrapped in bundles in the wire feeding unit 10. Pulling of the power unit 30, the fuse A is pulled out from the wire feeding unit 10 and entered into the drawing unit 20 for filtering, and the straightness of the fuse A filtered by the drawing unit 20 is adjusted , and finally, the fuse A enters the cutting unit 40 from top to bottom for cutting and is automatically inserted into the safety tube to complete the overall threading action.

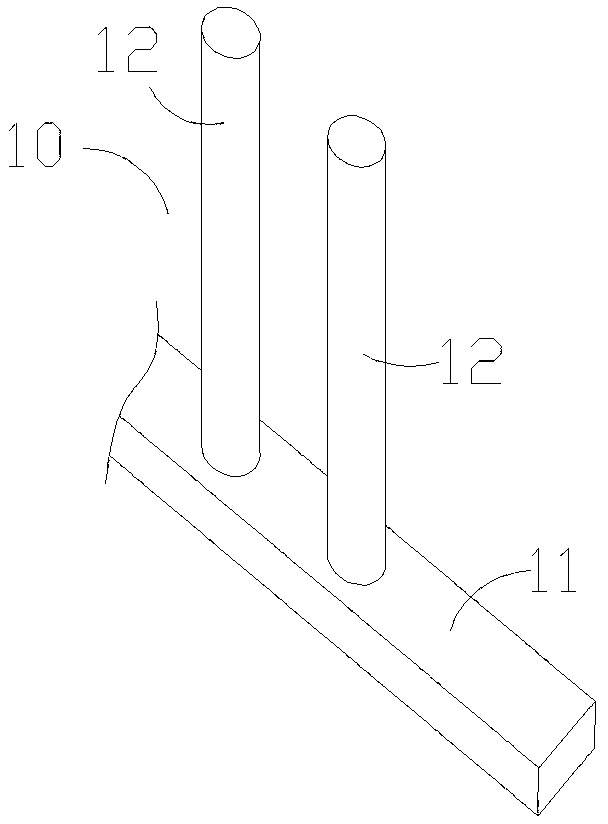

[0035] Such as Figures 2 to 3 As shown, the wire feeding unit 10 includes a bracket 11 and several posts 12, several posts 12 are fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com