Cooling device for interference fit of large-scale workpiece and assembly method thereof

A technology of interference fit and large workpieces, which is applied to components of pumping devices for elastic fluids, pump elements, non-variable pumps, etc., and can solve the problem of inability to clean the heating oil, splashing of heating oil, high risk, etc. problems, to achieve the effect of safe and reliable cooling process, avoiding property changes, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

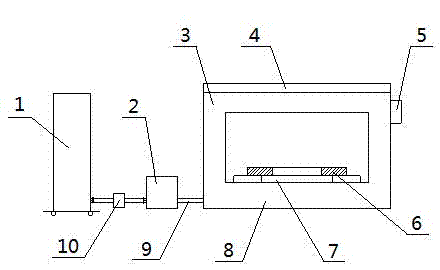

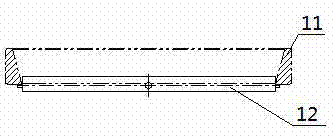

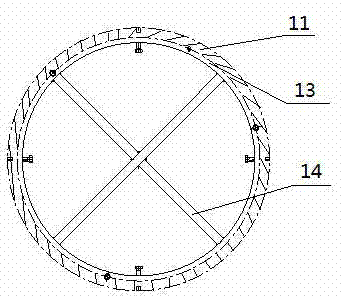

[0034] Such as figure 1 As shown, the present invention designs a large workpiece interference fit cooling device, including a liquid nitrogen tank 1, a cooling box 3, a liquid nitrogen vaporization device 2 and control equipment. The liquid nitrogen in the liquid nitrogen tank 1 is transported to the cooling box 3 through the pipeline 9, and the liquid nitrogen vaporization device 2 is arranged on the pipeline 9, and the liquid nitrogen is vaporized into a low-temperature gas, and then sent into the cooling box 3 through the pipeline 9, so that the cooling box The cooling medium in 3 is the low-temperature gas after the vaporization of liquid nitrogen. The top of the cooling box 3 is provided with a sealing cover 4, and after being put into the contained part 6, the sealing cover 4 is covered, so that the cooling box 3 becomes a closed space isolated from the outside world. The bottom of the cooling box 3 is provided with a mounting platform 8 for placing the contained part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com