Method for drawing columns and enlarging distances after replacing beams at high altitude in industrial factory building

A technology for industrial workshops and workshops, applied in building maintenance, construction, building construction, etc., can solve the problems of long construction period, many support measures, and large production impact, reduce the materials used for support and reinforcement measures, reduce construction costs, The effect of improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

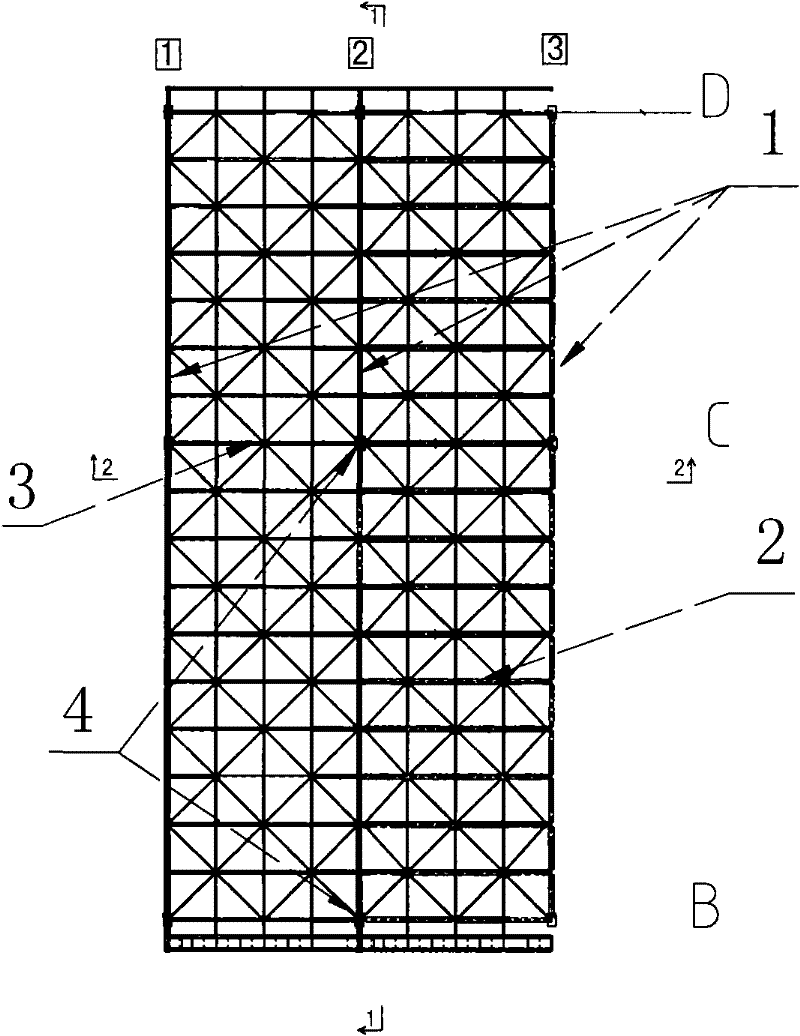

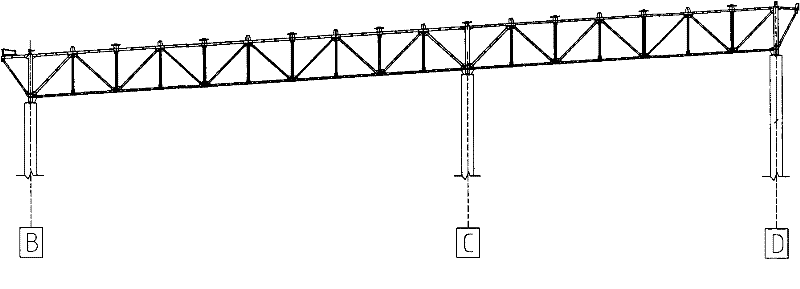

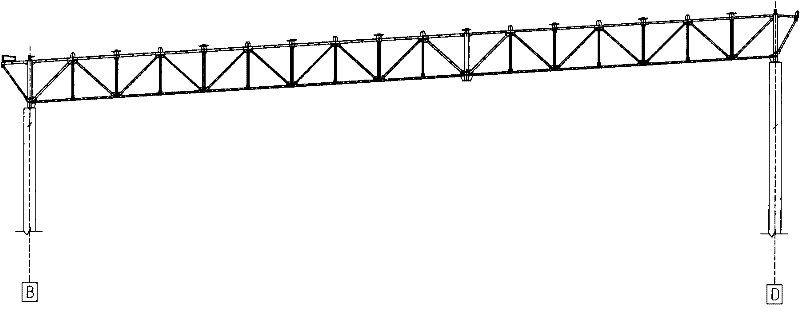

[0025] see now figure 1 , figure 2 and Figure 4 , figure 1 It is a schematic diagram of the roof steel structure system of an industrial plant, figure 2 before removing the pillar figure 1 1-1 view in and Figure 4 before removing the pillar figure 1 2-2 view in. As shown in the figure, the continuous casting workshop of a large steel factory needs to remove the reinforced concrete column (4) with a small steel column connected to the joist at the top of the column to expand the horizontal column and The project needs to change the column spacing of the original plant from 12m to 24m to add a 6-strand continuous casting machine facility.

[0026] Adopting the method for extracting columns and expanding distance after changing the beam at the high vacancy of the industrial factory building of the present invention, the following steps are specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com