Device and method for extracting sticky down by deeply processing down

A technology of threading down and deep processing, which is applied in the direction of heating/cooling fabrics, textiles and papermaking, fiber processing, etc. It can solve the problems of poor economic returns, many down raw materials, and low output, so as to achieve light wearing and use, and improve the quality of life. The effect of high market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

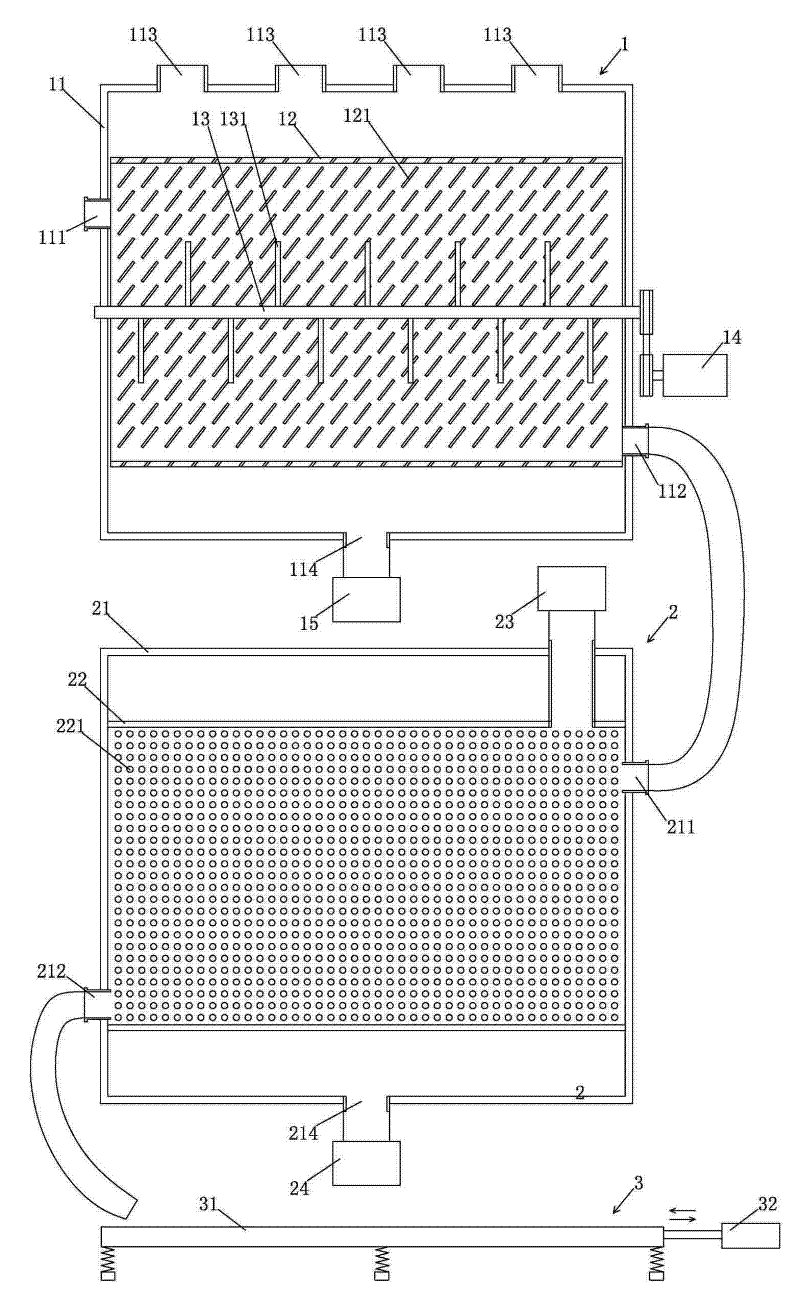

[0025] Such as figure 1 and figure 2 As shown, the eider down deep-processing extraction device of the present invention includes a flaked silk separation box 1, a neck hair silk separation box 2 and a velvet flying silk separation screen 3 connected in sequence.

[0026] Described flake yarn separation box 1 is made up of box body 11, the cylindrical sieve cylinder 12 and rotating shaft 13 that are horizontally placed in box body 11, driving motor 14, exhaust fan 15. The two ends of the screen drum 12 cooperate with the inner surfaces of the two ends of the casing 11 to prevent down from leaking between the screen drum and the casing. The rotating shaft 13 is arranged in the screen cylinder 12, and the rotating shaft 13 is provided with several radial struts 131, and one end of the rotating shaft 13 is connected with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com