Method for processing collagen peptide by using fish leftovers

A technology of collagen peptides and fish scraps, which is applied in the field of aquatic product processing and can solve problems such as limitations in the preparation of collagen peptides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

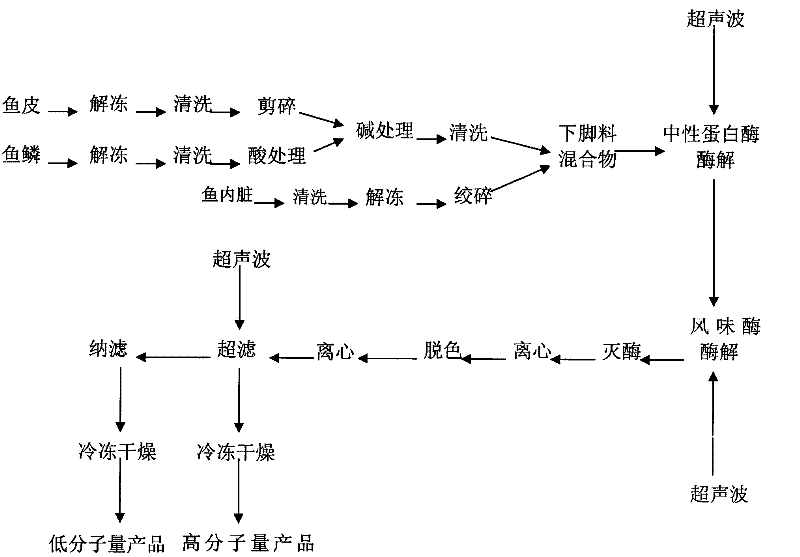

[0021] 1. Preparation of the fish waste mixture Firstly, the fish skin, fish scales, and fish viscera are processed separately to remove miscellaneous proteins and facilitate the dissolution of collagen. The fish skin is thawed, cleaned, shredded, soaked in 0.1mol / L NaOH 20 times its mass for 2 hours, and cleaned for later use; the fish scales are thawed, cleaned, soaked in 0.4mol / L HCL 20 times its mass for 2 hours, and its mass 20 times its mass 0.1mol / L NaOH soaked in 0.1mol / L NaOH for 2 hours, washed for later use; fish viscera were thawed, washed, and minced for later use; then the separately processed fish scraps were mixed to obtain a mixture of fish scraps for later use.

[0022] 2. Ultrasound promotes enzymatic hydrolysis of neutral protease. Weigh 20 g of the treated fish waste mixture and add 40 mL of deionized water. The ultrasonic frequency is 40kHz, the power is 200W, the initial pH value is adjusted to 7.0, the amount of enzyme added is 0.05%, the enzymolysis te...

example 2

[0032]1. Preparation of the fish waste mixture Firstly, the fish skin, fish scales, and fish viscera are processed separately to remove miscellaneous proteins and facilitate the dissolution of collagen. The fish skin is thawed, cleaned, shredded, soaked in 0.1mol / L NaOH 20 times its mass for 2 hours, and cleaned for later use; the fish scales are thawed, cleaned, soaked in 0.4mol / L HCL 20 times its mass for 2 hours, and its mass 20 times its mass 0.1mol / L NaOH soaked in 0.1mol / L NaOH for 2 hours, washed for later use; fish viscera were thawed, washed, and minced for later use; then the separately processed fish scraps were mixed to obtain a mixture of fish scraps for later use.

[0033] 2. Ultrasound promotes enzymatic hydrolysis with neutral protease. Weigh 20 g of the treated fish waste mixture and add 40 ml of deionized water. The ultrasonic frequency is 40kHz, the power is 400W, the initial pH value is adjusted to 7.0, the amount of enzyme added is 0.1%, the enzymolysis te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com