Preparation method of reversible agglomeration and re-dispersion latex based on amidine compound

A technology of redispersing glue and amidine compounds, which is applied in the field of reversible coagulation and redispersing latex preparation, can solve the problems of unreported coagulation of polymer particles and difficulties, and achieve the effect of easy control and process reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

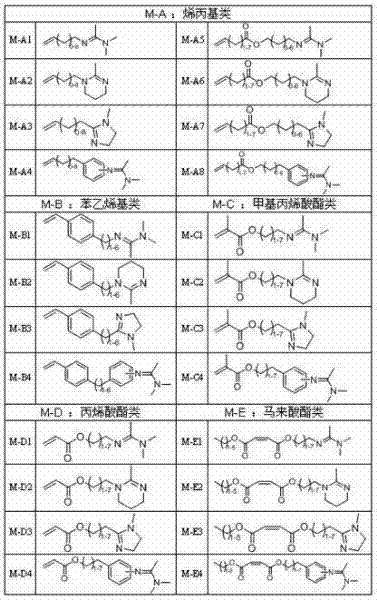

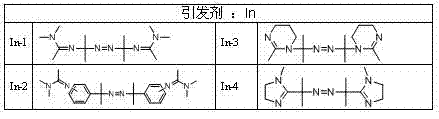

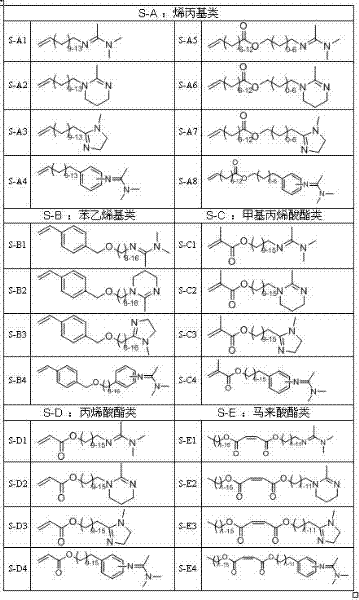

Method used

Image

Examples

Embodiment 1

[0048] (1) Add 0.125 parts of amidine-containing compound M-B2 (n=1) as a comonomer and 19 parts of deionized water into a 50ml three-necked bottle, and stir mechanically;

[0049] (2) Add 5 parts of monomeric styrene to the solution in step (1), pass nitrogen to remove oxygen for 15 minutes, and pass carbon dioxide gas;

[0050] (3) Weigh 0.094 parts of azodiisopropylimidazoline hydrochloride (V-50), dissolve it in 1 part of deionized water and add it to the monomer emulsion to initiate polymerization;

[0051] (4) React at 70°C for 8 hours and stop the reaction;

[0052] (5) Adjust the pH of the obtained polymer latex to 9~10 with a small amount of 0.1M sodium hydroxide aqueous solution, so that the latex particles can be coagulated, and the latex particles can be redispersed by carbon dioxide gas and ultrasonic to obtain a stable polymer latex.

[0053] The conversion rate of the final styrene monomer in the polymerization system was 94.3%, and the conversion rate of the c...

Embodiment 2

[0055] (1) Add 0.25 parts of amidine-containing compound S-A5 (n=8, m=0) as a reactive surfactant, 19 parts of deionized water into a 50ml three-necked bottle, and stir mechanically;

[0056] (2) Add 5 parts of monomeric styrene to the solution in step (1), pass nitrogen to remove oxygen for 15 minutes, and pass carbon dioxide gas;

[0057] (3) Weigh 0.094 parts of azodiisopropylimidazoline hydrochloride (V-50), dissolve it in 1 part of deionized water and add it to the monomer emulsion to initiate polymerization;

[0058] (4) React at 65°C for 5 hours and stop the reaction;

[0059] (5) The obtained polymer latex was subjected to nitrogen gas flow at 70°C for 0.5 hours to agglomerate the latex particles, and carbon dioxide gas and ultrasound to redisperse the latex particles to obtain a stable polymer latex.

[0060] The final conversion rate of styrene monomer in the polymerization system was 97.6%. Gel permeation chromatography (GPC) was used to measure the molecular weig...

Embodiment 3

[0062] (1) Add 0.125 parts of amidine-containing compound M-B2 (n=1) as a comonomer, 0.125 parts of dodecylamine hydrochloride as a surfactant, and 19 parts of deionized water in a 50ml three-necked bottle. stir;

[0063] (2) Add 5 parts of monomeric styrene to the solution in step (1), pass nitrogen to remove oxygen for 15 minutes, and pass carbon dioxide gas;

[0064] (3) Weigh 0.047 parts of azodiisopropylimidazoline hydrochloride (V-50), dissolve it in 1 part of deionized water and add it to the monomer emulsion to initiate polymerization;

[0065] (4) React at 70°C for 8 hours and stop the reaction;

[0066] (5) The obtained polymer latex can be coagulated with a small amount of 0.1M sodium hydroxide aqueous solution, and the latex particles can be redispersed by passing carbon dioxide gas and ultrasonic to obtain a stable polymer latex.

[0067] The conversion rate of the final styrene monomer in the polymerization system was 99.9%, and the conversion rate of the comon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com