Device and method for moulding and forming micro-turbine

A technology of micro-turbine and compression molding, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of unsuitable mass production, low material utilization rate, high processing cost, etc., and achieve good comprehensive mechanical properties and material utilization rate High, high processing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

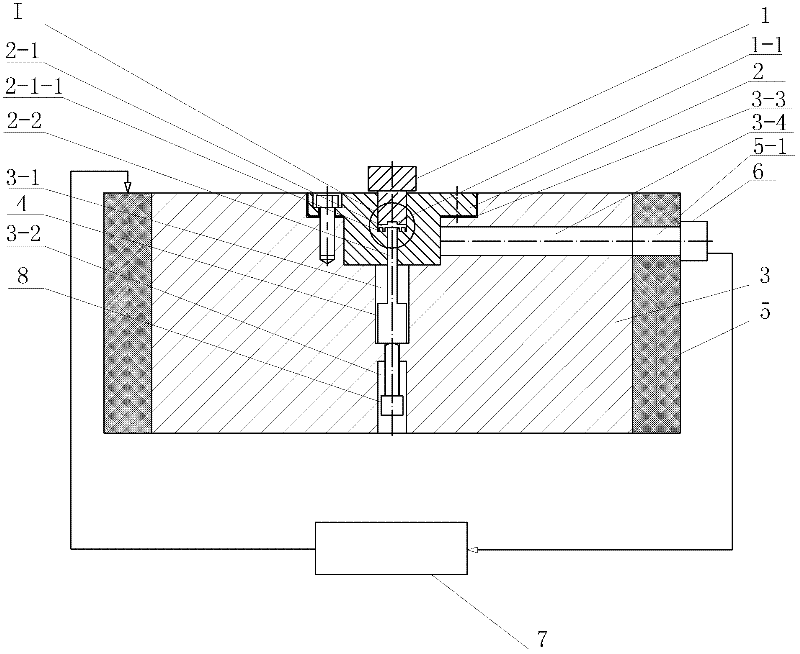

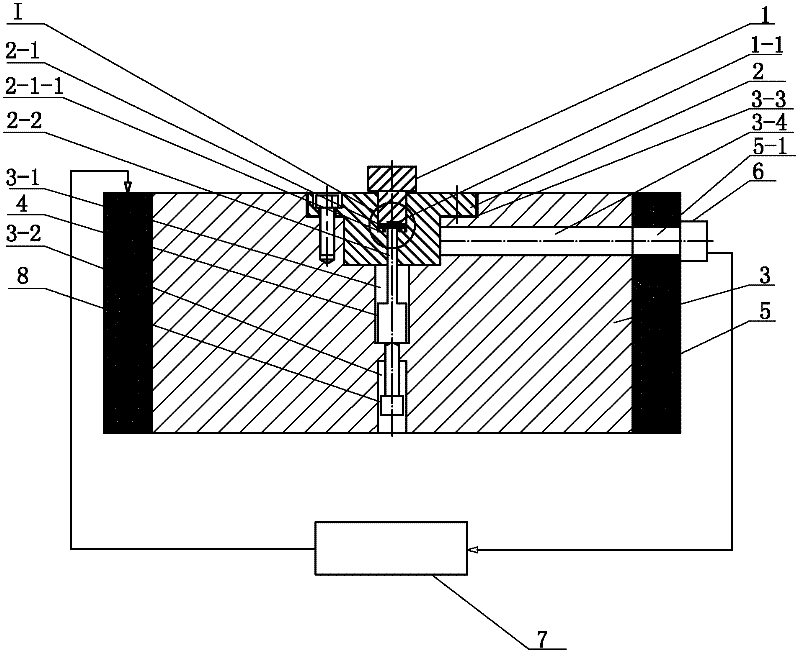

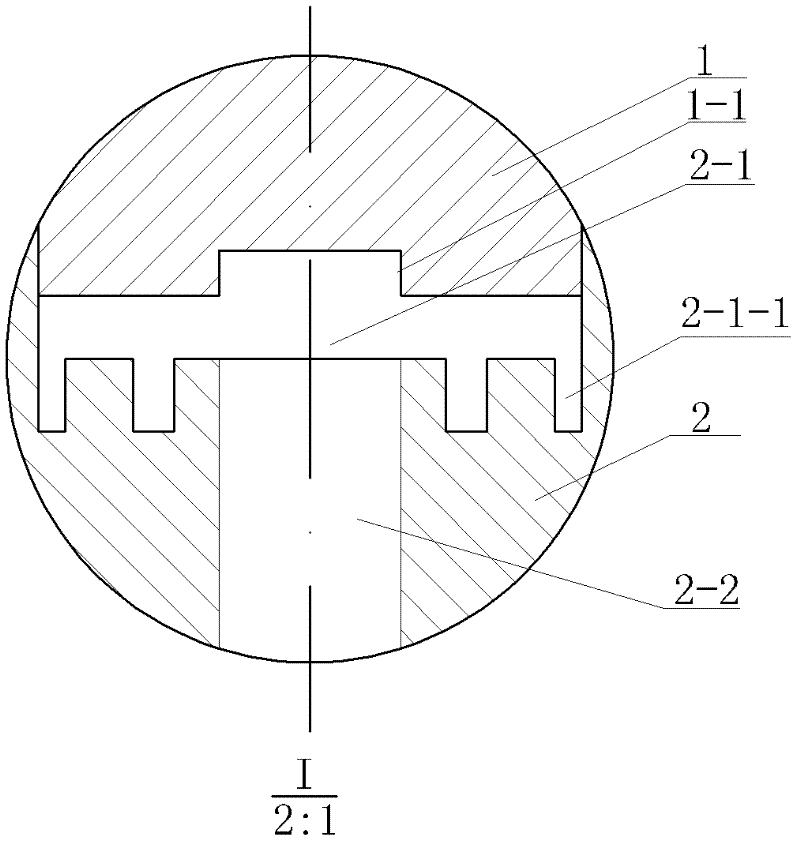

[0015] Specific implementation mode one: combine figure 1 and image 3 Describe this embodiment, the micro-turbine molding device of this embodiment includes a punch 1, a die 2, a die base 3, a push rod 4, an electric heating element 5, a temperature sensor 6, a temperature controller 7 and a first screw 8 The middle part of the upper end surface of the die base 3 is provided with a first groove 3-3, the die 2 is placed in the first groove 3-3 of the die base 3, and the die 2 and the die base 3 are detachably connected The middle part of the lower end surface of the die base 3 is provided with a third hole 3-2, and the die base 3 is provided with a second hole communicating with the two between the first groove 3-3 and the third hole 3-2. Hole 3-1, a fourth hole 3-4 communicated with the first groove 3-3 is provided radially on the side wall of the die holder 3, and a forming groove 2-1 is provided in the middle of the upper end surface of the die 2 , the middle part of the ...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination figure 1 The present embodiment will be described. The materials of the punch 1 , the die 2 , the die holder 3 and the ejector pin 4 of the present embodiment are all 5CrNiMo. With such settings, the material performance is reliable and meets the design requirements. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 1 Describe this embodiment, the die 2 and the die base 3 of this embodiment are detachably connected by at least four second screws. In this way, the die is fixed on the die base with the second screw, which is convenient for installation and disassembly, and the die will not be removed from the die base due to the friction between the part and the inner wall of the die during the ejection process after the molded part is formed. Out, and has a uniform force, not easy to cause damage or deformation of parts. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com