Electronic heating module

An electronic and heating body technology, applied in circuits, electric light sources, electrical components, etc., can solve the problems of high manufacturing cost and difficult control of manufacturing quality, and achieve the effects of low cost, simple structure and good heat dissipation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

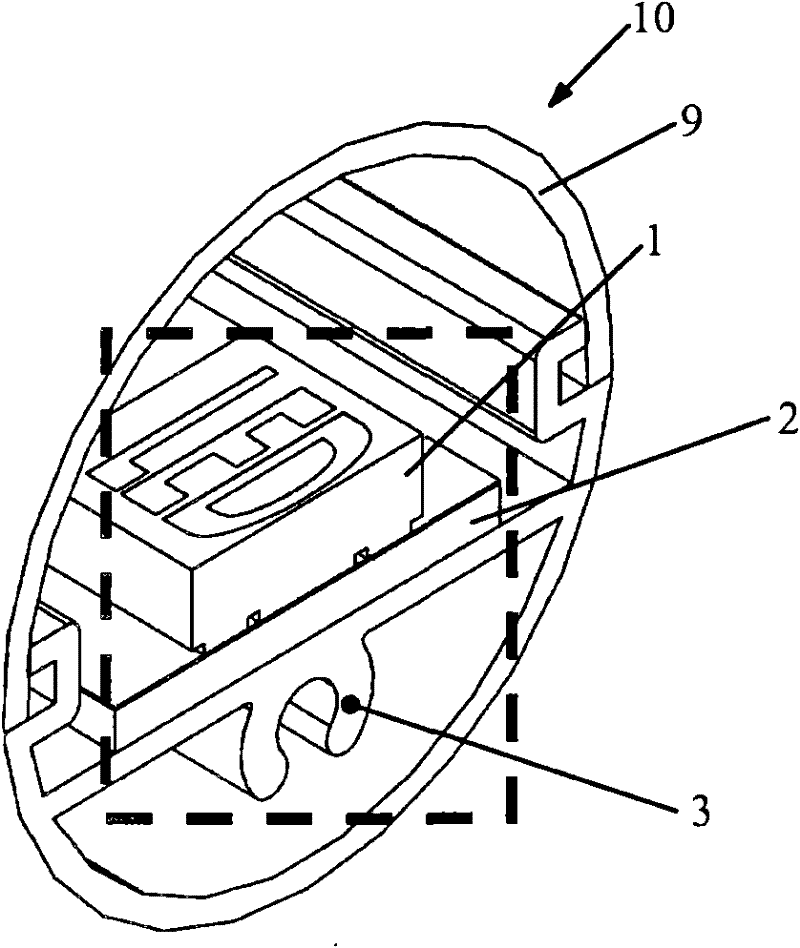

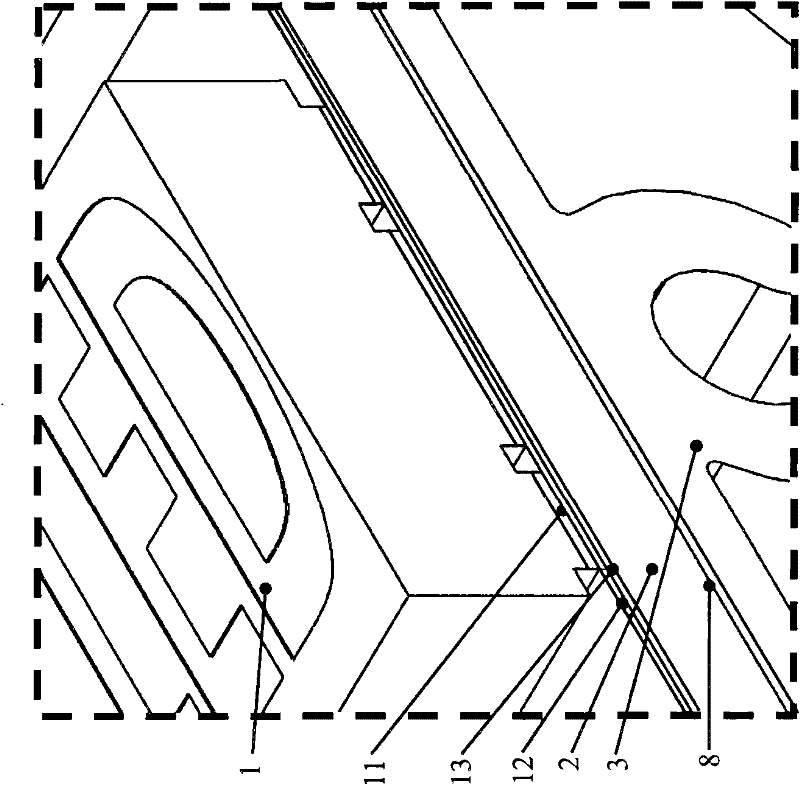

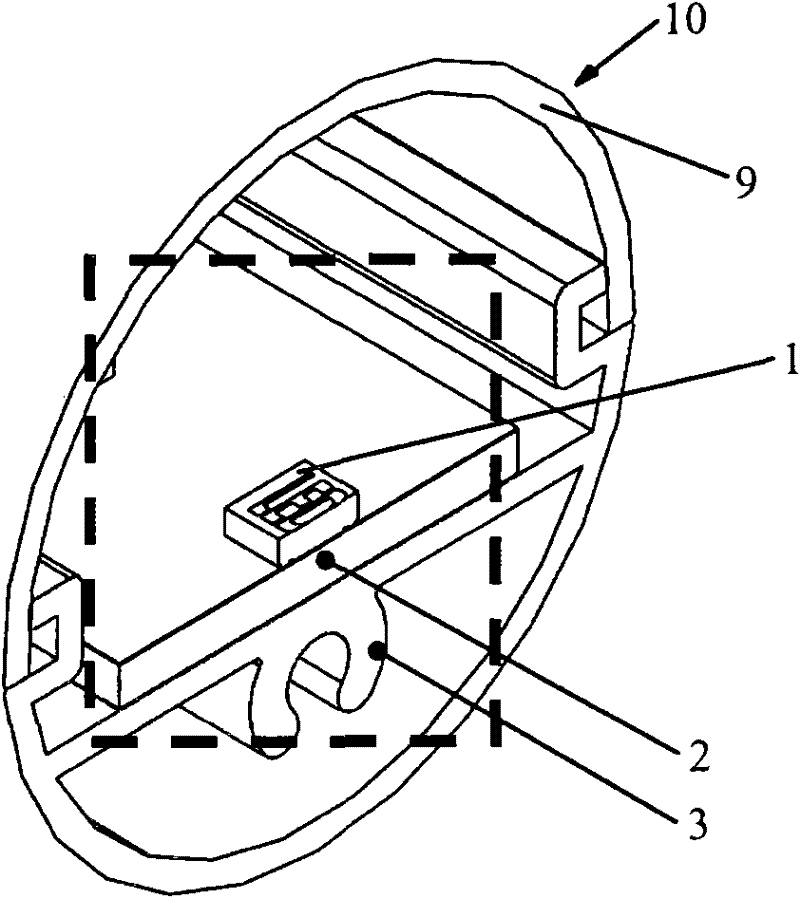

[0021] Figure 3a , 3b respectively show a schematic diagram of an electronic heating module designed as an LED module according to the first embodiment of the present invention and Figure 3a Enlarged view at the dotted line. It should be pointed out that although an LED module is used as an example here, the electronic heating module is not limited to a light emitting module, and it can be any electronic module that generates heat to achieve other functions. The light emitting module is not limited to the LED module, and it can be any module capable of emitting light.

[0022] From Figure 3a , 3b, it can be seen that the LED module includes a light cover 9 and at least one LED 1 , a substrate 2 and a heat sink 3 disposed in the light cover 9 . Here, the substrate 2 may be a substrate with poor thermal conductivity, such as an FR-4 substrate.

[0023] Different from the prior art, a through hole 4 penetrating through the thickness of the substrate 2 in the vertical direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com