Reel and transformer utilizing same

A transformer and winding frame technology, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve problems such as pin displacement, welding inconvenience, winding frame melting loss, etc., so as to solve the problem of pin displacement and reduce theoretical Line man-hours, improve the effect of tin overflow or tin hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Some typical embodiments embodying the features and advantages of the present invention will be described in detail in the description in the following paragraphs. It should be understood that the present invention can have various changes in different embodiments, but none of them departs from the scope of the present invention, and the description and drawings therein are used as illustrations in nature, not to limit the present invention. invention.

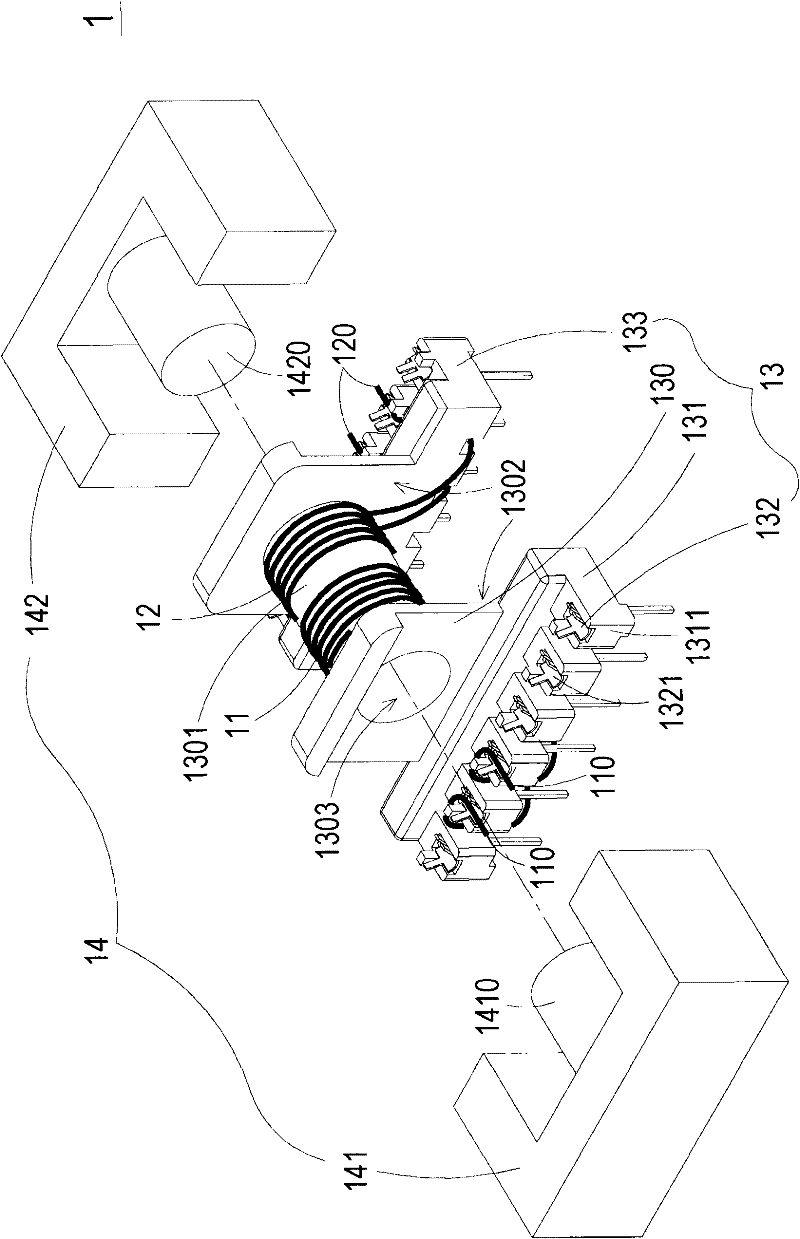

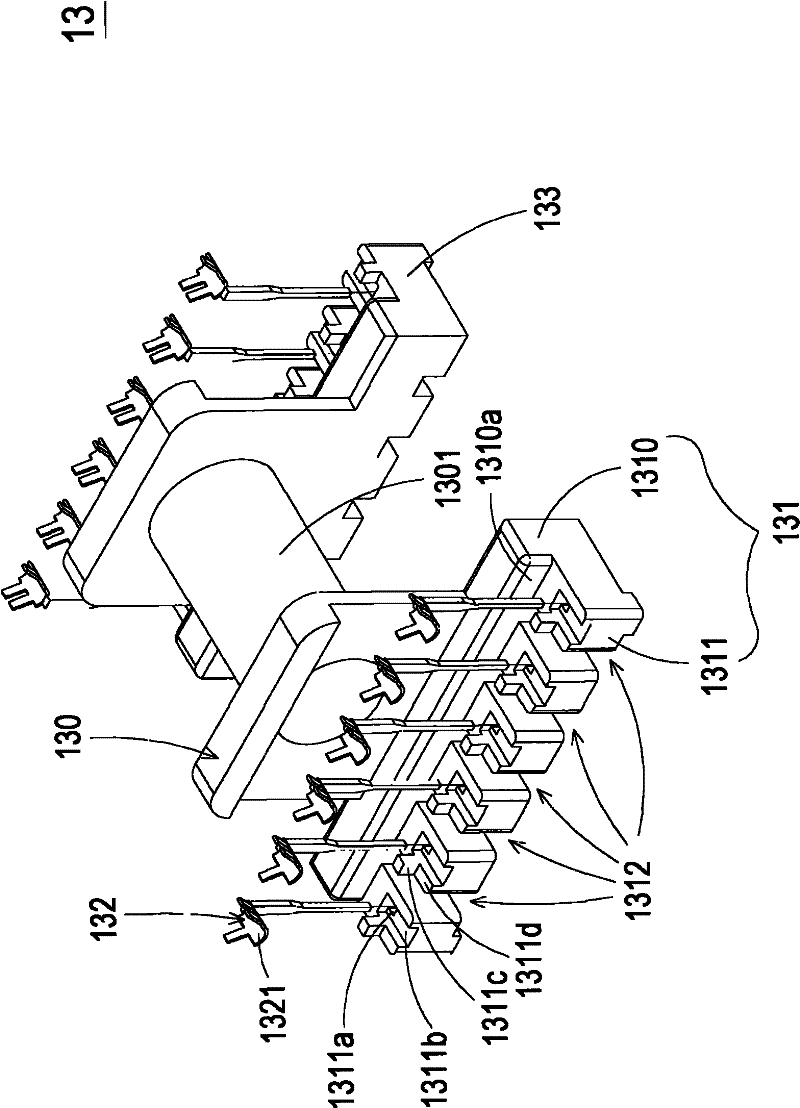

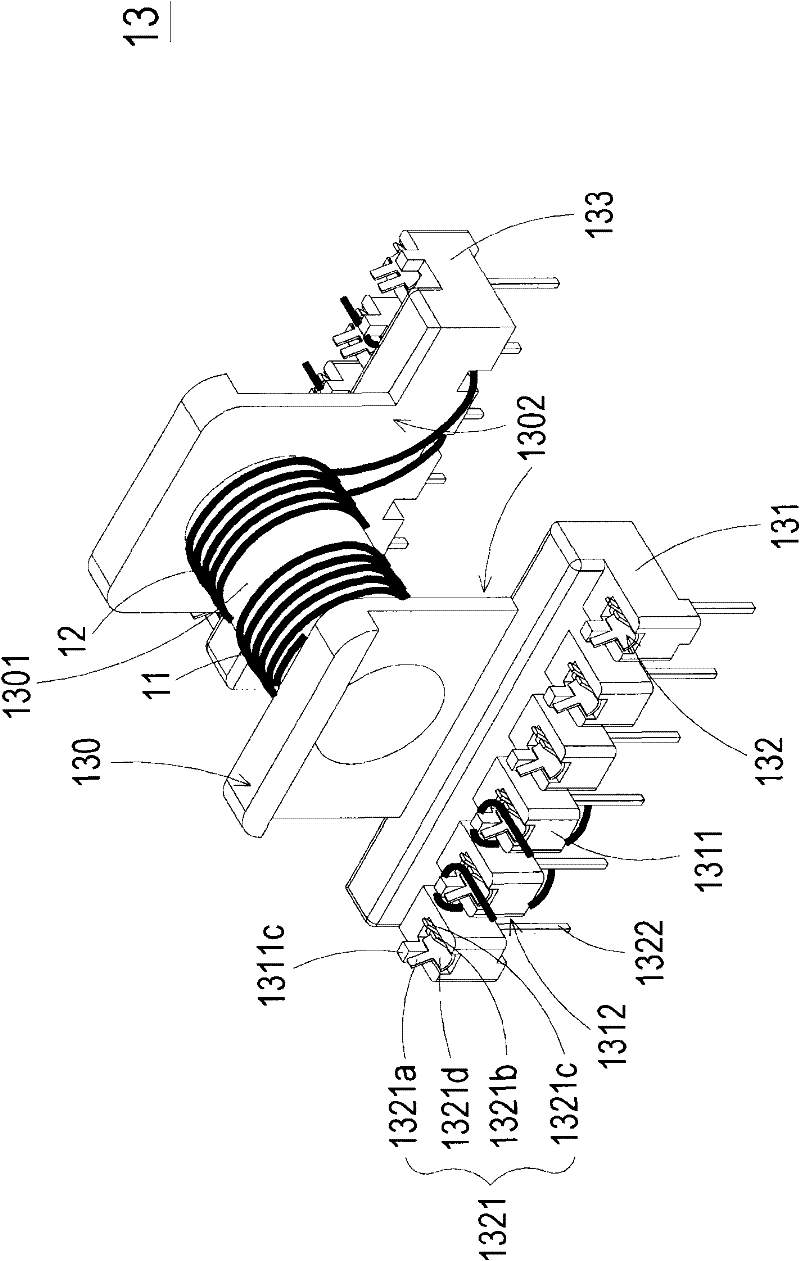

[0037] see figure 1 , which is a schematic diagram of a transformer structure in a preferred embodiment of the present invention. like figure 1 As shown, the transformer 1 of the present invention at least includes a primary winding 11, a secondary winding 12, a winding frame 13 and a magnetic core set 14, wherein the winding frame 13 includes a body 130, a first socket 131 and a plurality of clips Pin 132 is fixed. In this embodiment, the primary winding 11 and the secondary winding 12 can be a single core wire or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com