Thin-walled steel fiber concrete pipe

A steel fiber concrete and thin-walled technology, which is applied to pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of ordinary concrete pipes that are difficult to meet the requirements, the welding workload is large, and the time is long, so as to achieve good joints Water-tightness, high production efficiency, and the effect of reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

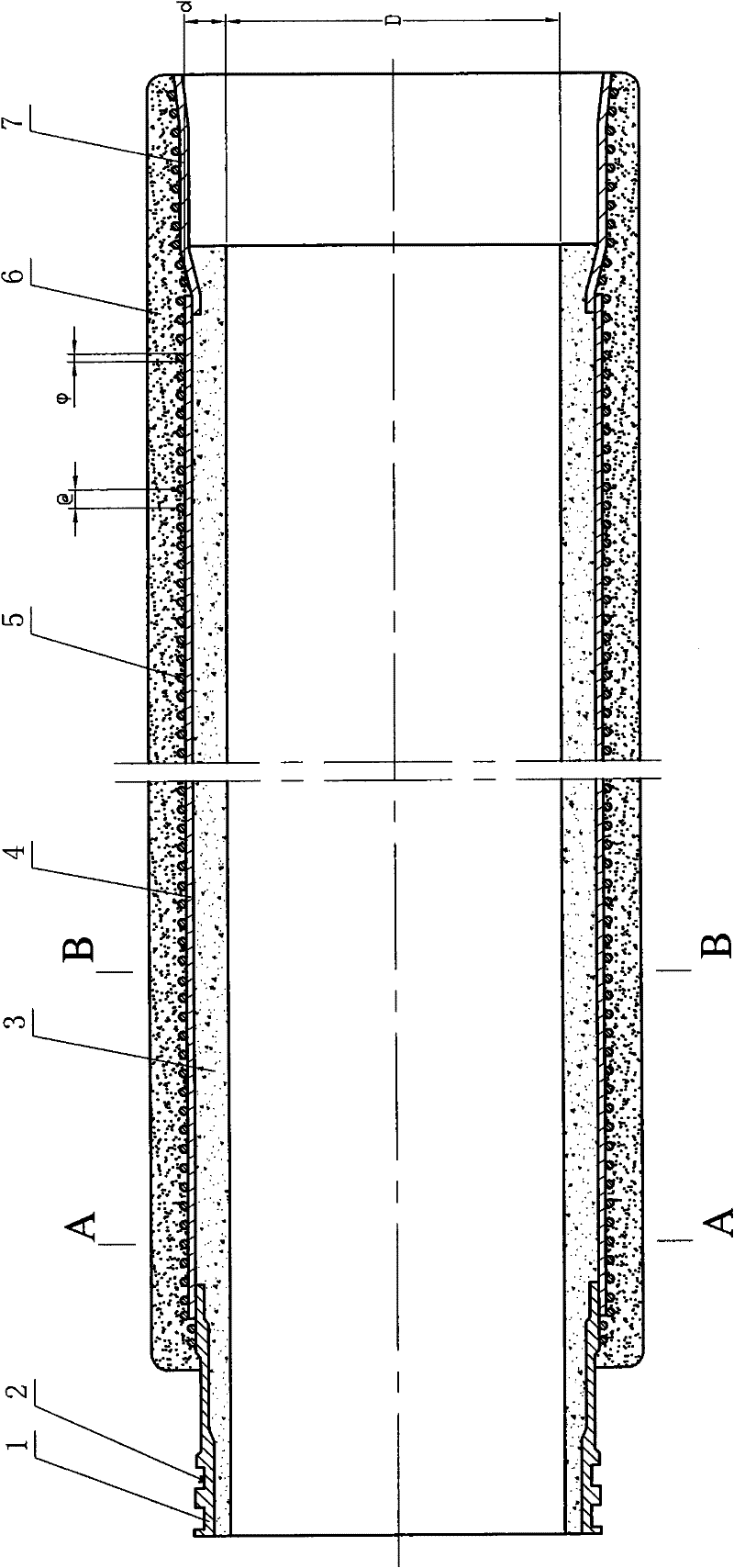

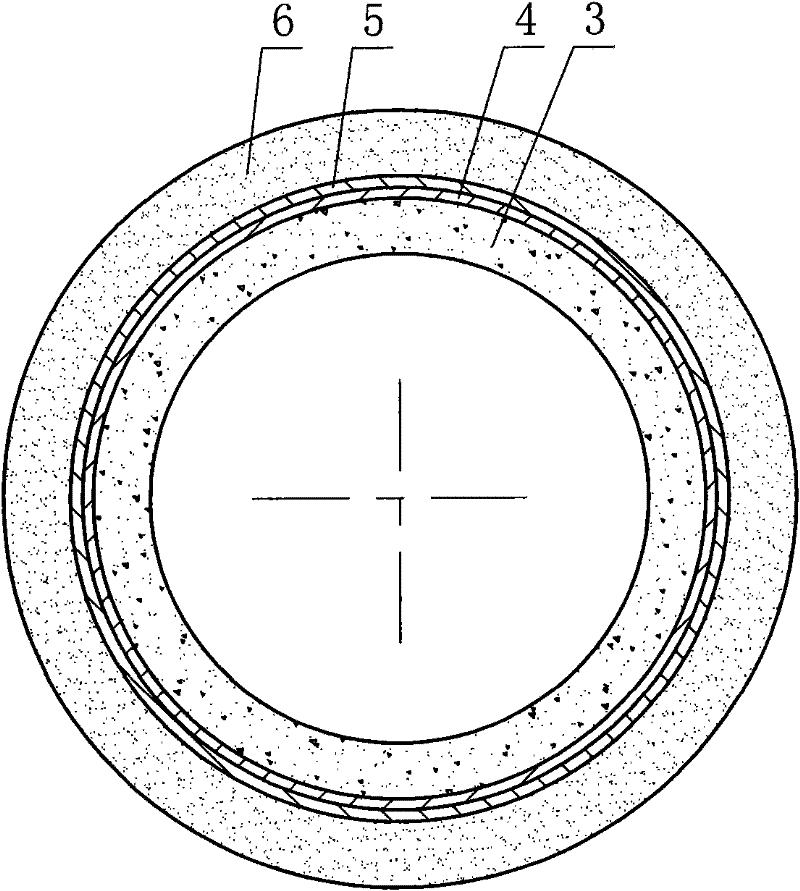

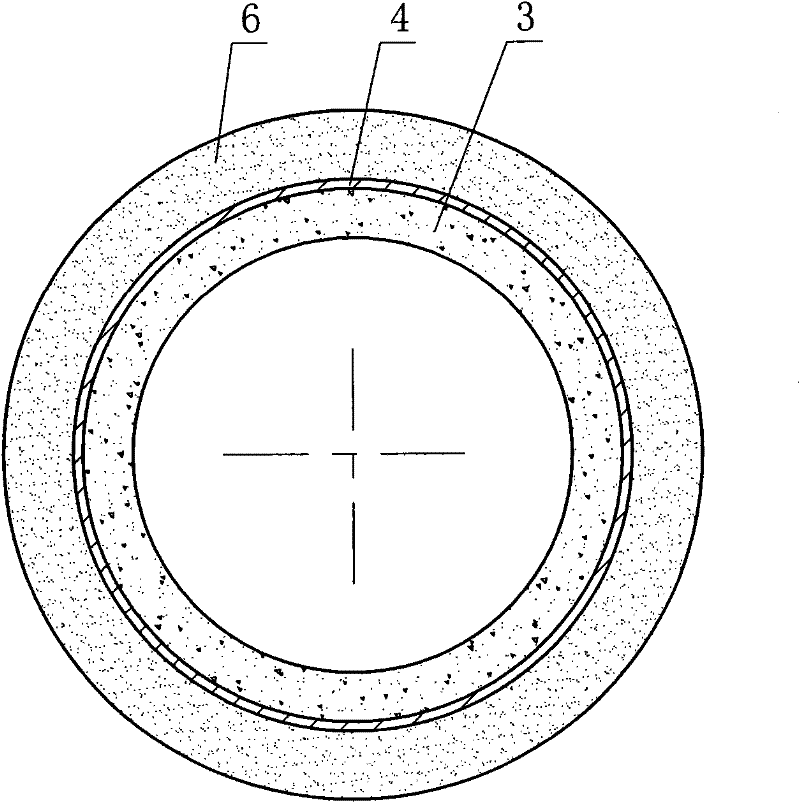

[0023] 1. Thin-walled steel fiber concrete pipe, pipe inner diameter D: 1400mm, pipe core wall thickness d: 47mm, prestressed steel wire diameter φ: 5mm, prestressed steel wire pitch: 10mm.

[0024] 2. Thin-walled steel fiber concrete pipe, pipe inner diameter D: 2000mm, pipe core wall thickness d: 80mm, prestressed steel wire diameter φ: 6mm, prestressed steel wire pitch: 14mm.

[0025] 3. Thin-walled steel fiber concrete pipe, pipe inner diameter D: 2600mm, pipe core wall thickness d: 130mm, prestressed steel wire diameter φ: 7mm, prestressed steel wire pitch: 18mm.

[0026] 4. Thin-walled steel fiber concrete pipe, pipe inner diameter D: 3600mm, pipe core wall thickness d: 200mm, prestressed steel wire diameter φ: 8mm, prestressed steel wire pitch: 28mm.

[0027] The steel fiber concrete pipe core of the present invention is formed by one-time casting, and the pitch of the prestressed steel wire wound on the outer wall of the steel cylinder is relatively dense, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com