Technology for producing methyl chloride by gas-liquid phase non-catalytic method

A non-catalytic, methyl chloride technology, applied in chemical instruments and methods, organic chemistry, preparation of halogenated hydrocarbons, etc., can solve problems such as high cost, poor product quality, complex production technology, etc., and achieve high selectivity and reasonable design , the effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

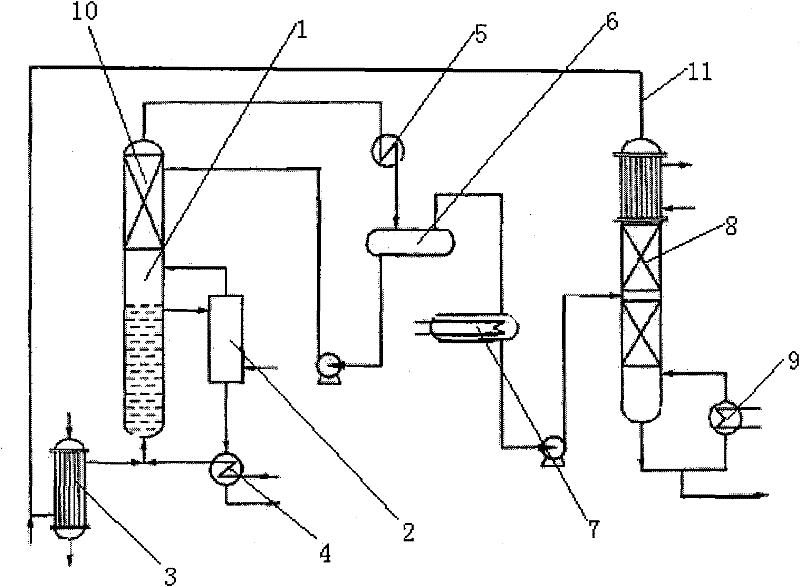

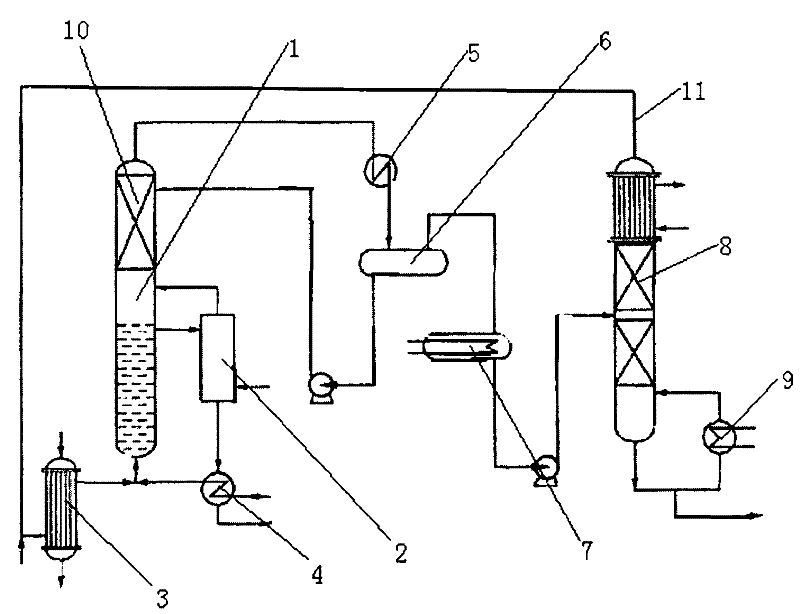

[0012] refer to figure 1 , reactor (1), stripper (2), left heat exchanger (3), right heat exchanger (4), condensation tower (5), reflux tank (6), condenser (7), hydrogen chloride separation The tower (8), reboiler (9), and distillation tower (10) are assembled into one body through connecting pipelines (11) according to their system functions.

[0013] Under pressure, liquid methanol and hydrogen chloride are reacted to synthesize methyl chloride. Since the one-way reaction of methanol and hydrogen chloride cannot be completed, further reaction is performed after separation.

[0014] Methanol and excess 10% hydrogen chloride enter the reactor (1) from the lower part of the reactor (1) after heat exchange, the reaction temperature is 120° C., and the pressure is 1.06 MPa. On the reactor (1) is a distillation column (10), the reflux ratio of distillation is controlled at 1-2, and the methyl chloride saturated by hydrogen chloride is separated. Unreacted methanol and generated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com