Method for controlling setting time and early hydration speed of magnesium potassium phosphate cement

A technology of potassium magnesium phosphate cement and setting time, which is applied in the field of early-strength and rapid-hardening cement cementitious materials, can solve the problems of inconspicuous retarding effect, difficult control, and influence on the fluidity and early strength of the hardened body of magnesium phosphate cement, and achieve Solve the effect of limited retarding effect and poor operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

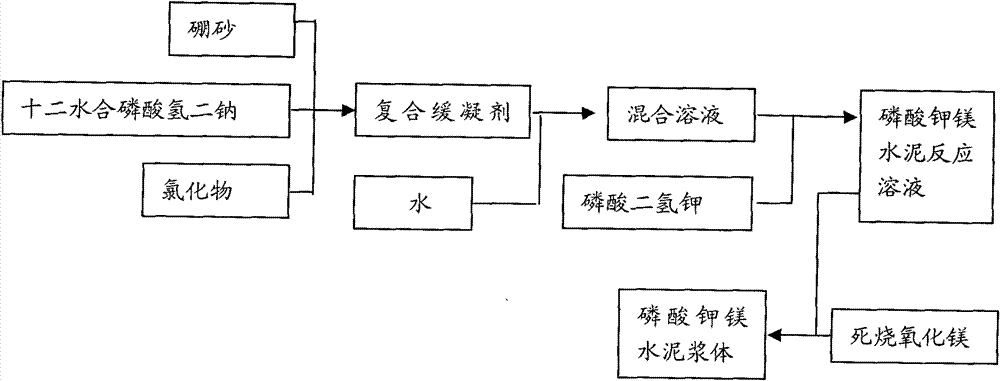

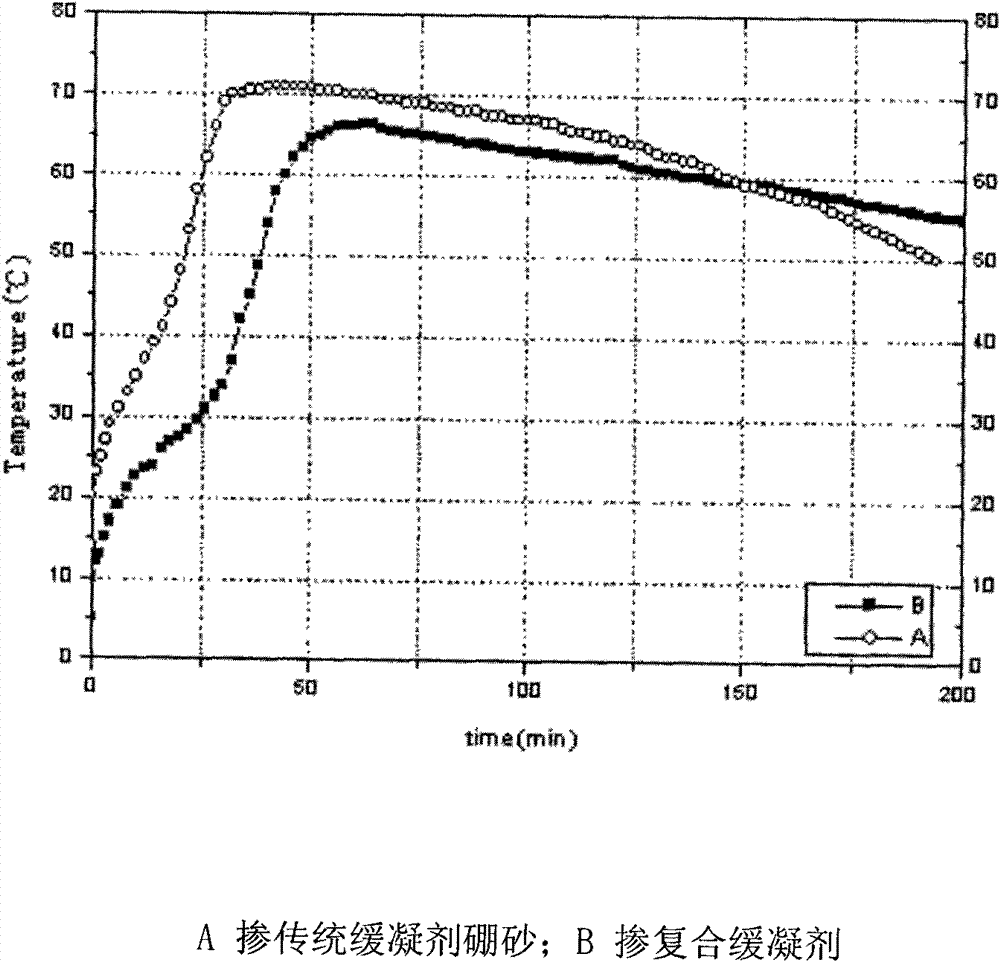

[0036] The traditional retarder borax, which accounts for 10% of the cement mass, is mixed into the potassium magnesium phosphate cement. First, the borax and potassium dihydrogen phosphate are added to the water. Procedure, first take the slow speed stirring for 1-2 minutes, then adjust to the fast rotating gear and stir for 1-2 minutes to obtain the potassium magnesium phosphate cement reaction solution, continue to adjust to the slow speed stirring gear, slowly put in dead-burned magnesium oxide, and wait for it to be put in After completion, adjust to rapid stirring for 1 to 2 minutes to obtain potassium magnesium phosphate cement slurry (A).

[0037]The same proportion of potassium magnesium phosphate cement is mixed with a composite retarder that accounts for 10% of the cement mass, and the composite retarder is added to the water. , stir at a slow speed for 1 minute, add potassium dihydrogen phosphate, continue to stir at a slow speed for 1 to 2 minutes, then adjust to ...

Embodiment 2

[0042] Add compound retarder into potassium magnesium phosphate cement, adjust the content of chloride in compound retarder, add compound retarder with different chloride content into water, use SJ-160 double shaft speed at room temperature The manual control program of the cement slurry mixer is to stir at a slow speed for 1 minute, add potassium dihydrogen phosphate, continue to stir at a slow speed for 1 to 2 minutes, and then adjust to the fast rotation gear and stir for 1 to 2 minutes to obtain a potassium magnesium phosphate cement reaction solution. Continue to adjust to the slow speed stirring gear, slowly put in the dead-burned magnesium oxide, and after the addition is completed, adjust to the fast stirring speed for 3 to 5 minutes to obtain potassium magnesium phosphate cement slurry.

[0043] The setting time of the slurry was tested with a Vicat instrument at an ambient temperature of 20° C., and the compressive strength of the hardened body was tested with a cylin...

Embodiment 3

[0047] Mix the composite retarder into potassium magnesium phosphate cement, adjust the content of disodium hydrogen phosphate dodecahydrate in the composite retarder, add the composite retarder with different content of disodium hydrogen phosphate dodecahydrate into water, Use the manual control program of the SJ-160 double-shaft speed cement slurry mixer at room temperature, stir at a slow speed for 1 minute, add potassium dihydrogen phosphate, continue to stir at a slow speed for 1 to 2 minutes, and then adjust to the fast rotation gear and stir for 1 to 2 minutes to obtain the potassium magnesium phosphate cement reaction solution, continue to adjust to the slow speed stirring gear, slowly put in dead-burned magnesium oxide, and after the addition is completed, adjust to rapid stirring for 3 to 5 minutes to obtain potassium magnesium phosphate cement slurry.

[0048] The setting time of the slurry was tested with a Vicat instrument at an ambient temperature of 20° C., and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com