Composite retarder for controlling setting time and hydration heat release characteristic of potassium magnesium phosphate cement paste and control method of composite retarder

A technology of potassium magnesium phosphate cement and composite retarder, which is applied in the field of composite retarder and its control, which can solve the problem of corrosion of steel, high calcining temperature of dead-burned magnesium oxide powder, and inability to change the hydration of magnesium phosphate cement slurry Concentrated release of heat and other issues to achieve the effect of avoiding corrosion and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for controlling the coagulation time and hydration of the potassium phosphate magnesium cement slurry, the specific steps are as follows:

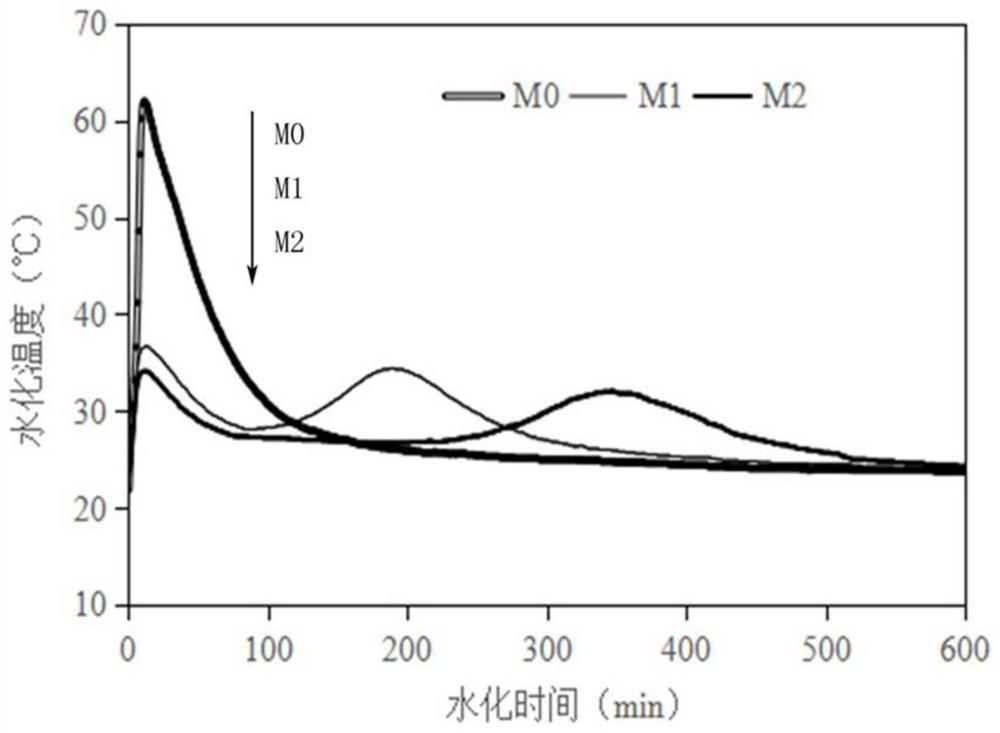

[0034] (1) Nitrite, zinc oxide, boroni and duodenate sodium hydrogen phosphate are mixed in a certain proportion, and form a composite loose agent (specifically shown in Table 1). In this embodiment, the composition of the three composite roller is selected, and the specific is as follows:

[0035] M0 group: The composite suspension is 1 parts by mass of boron sand and 1 parts by mass of die sodium hydrogen phosphate.

[0036] M1 group: Compound suspension is 1 parts by mass of boron sand, 1 parts by mass of sodium hydrogen sodium hydrogen phosphate, 0.36 parts by mass of nitrite and 0.04 parts by mass of zinc oxide.

[0037] M2 group: Compound suspension is 1 parts by mass of boron sand, 1 parts by mass of die sodium hydrogen sodium hydrogen phosphate, 0.76 parts by mass of nitrite and 0.04 parts by mass of zinc oxide.

[0038...

Embodiment 2

[0052] A method for controlling the coagulation time and hydration of the potassium phosphate magnesium cement slurry, the specific steps are as follows:

[0053] (1) Nitrite, zinc oxide, boron sand and dodeca sodium hydrogen phosphate are mixed in a certain proportion of mixing, and formulating a composite loose agent (specifically, as shown in Table 2). In this embodiment, the composition structure of the two composite roller is selected, and the specific is as follows:

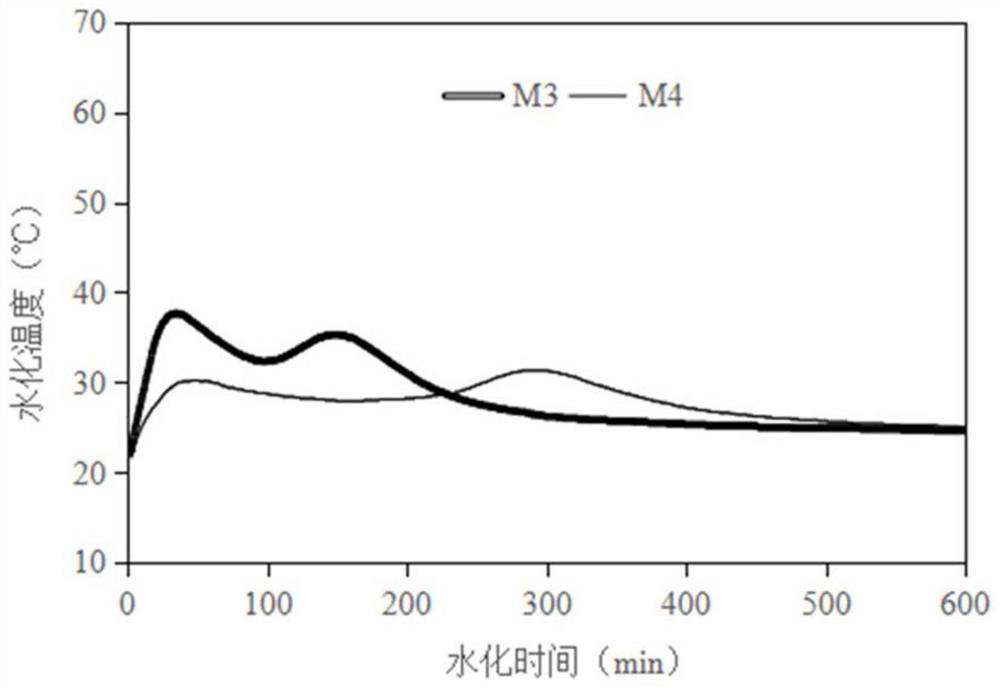

[0054] M2 group: Compound suspension is 1 parts by mass of boron sand, 1 parts by mass of die sodium hydrogen sodium hydrogen phosphate, 0.76 parts by mass of nitrite and 0.04 parts by mass of zinc oxide.

[0055] M3 group: Compound suspension is 1 parts by mass of boroni, 1 parts by mass of die sodium hydrogen phosphate, 0.4 parts by mass of nitrite and 0.4 parts by mass of zinc oxide.

[0056] (2) Add the composite cyusion agent to quantitative water, stir well, resulting in a homogeneous mixed solution.

[0...

Embodiment 3

[0068] A method for controlling the coagulation time and hydration of the potassium phosphate magnesium cement slurry, the specific steps are as follows:

[0069] (1) Nitrite, zinc oxide, boron sand and dodecini sodium hydrogen hydrogen phosphate are mixed in a certain proportion, forming a composite loose agent (as shown in Table 3). In this embodiment, the composition structure of the two composite roller is selected, and the specific is as follows:

[0070] M3 group: Compound suspension is 1 parts by mass of boroni, 1 part of die sodium hydrogen sodium hydrogen sodium hydrogen, 0.76 parts by mass of nitrite and 0.04 parts by mass of zinc oxide.

[0071] M4 group: Compound suspension is 1 parts by mass of boroni, 1 mass of die sodium hydrogen sodium hydrogen sodium hydrogen, 0.6 parts by mass of nitrite and 0.6 parts by mass of zinc oxide.

[0072] (2) Add the composite cyusion agent to quantitative water, stir well, resulting in a homogeneous mixed solution.

[0073] M3 group: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com