High color rendering light emitting diode and manufacture method thereof

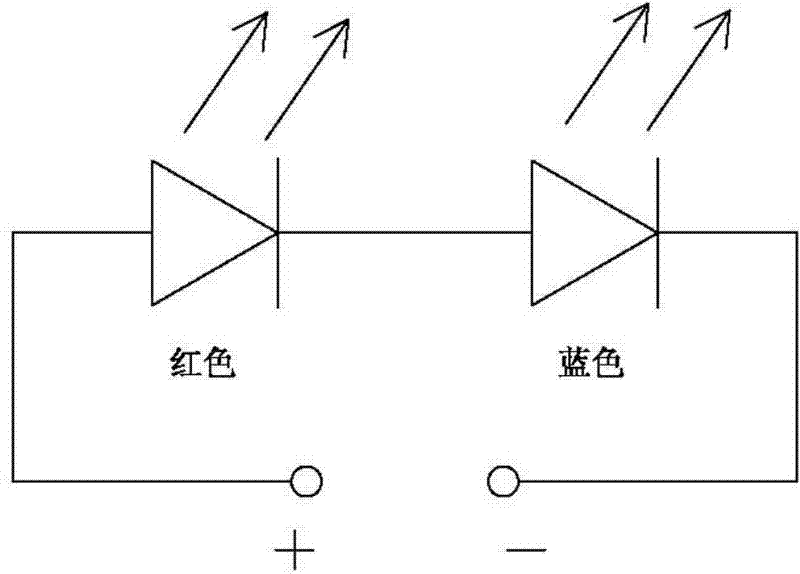

A technology of light-emitting diodes and high color rendering, applied in electrical components, electric solid-state devices, circuits, etc., can solve the problems of ordinary white light lacking deep red spectrum, small spectral width, discontinuity, etc., to improve low test index, luminous Uniform color and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

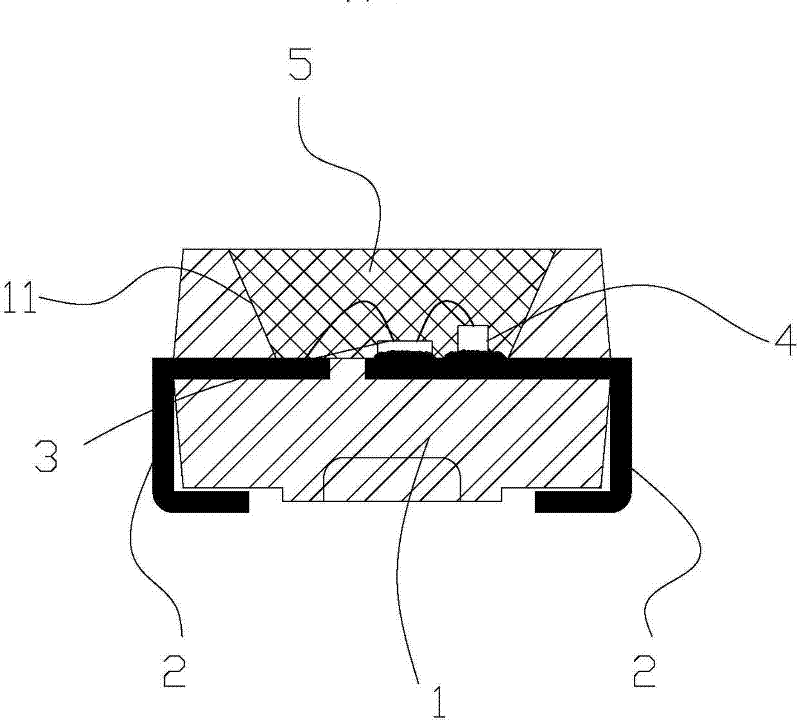

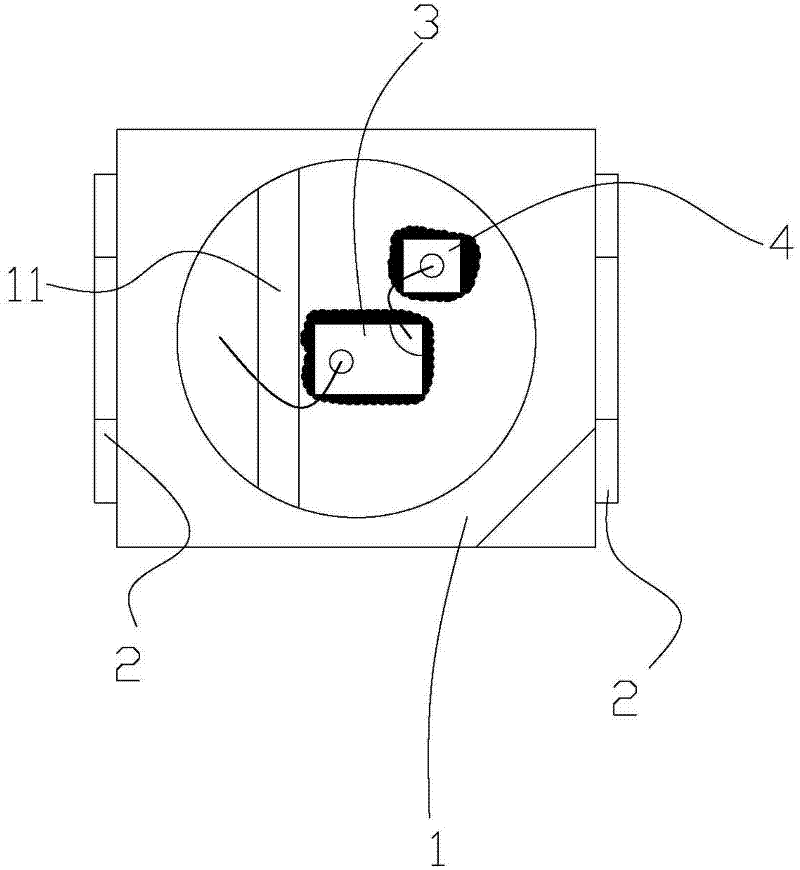

[0023] The chip setting of this method can adopt the structure that the blue LED chip 3 is arranged horizontally in the cup chamber 11 with the two poles, and the red LED chip 4 is vertically arranged in the cup chamber 11 with the two poles. For the patch-type support 1, A bracket pin 2 is directly introduced into the bottom of the cup chamber 11, and the lower pole of the red LED chip 4 can be directly fixed with the bracket pin 2 to form a connection relationship, while the upper pole is connected to the blue LED chip by a metal wire. 3, the blue LED chip 3 is also connected to another bracket pin 2 by a metal wire, so as to lead out the two poles of the whole series structure; 2. Therefore, one pole below the red LED chip 4 is directly fixedly connected to the lid cup chamber 11, and the other connections are the same; since the blue LED chip 1 and the red LED chip 2 need to ensure the same polarity orientation, there are generally two connection methods One is the positiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com