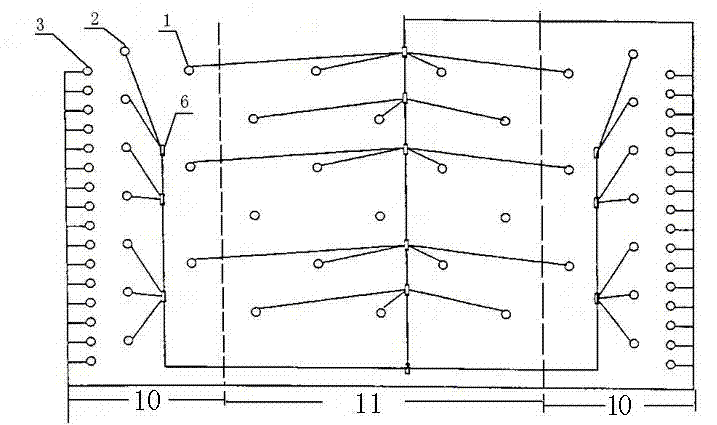

Multi-row micro-differential roadbed deep hole blasting construction method

A technology of deep hole blasting and construction method, which is applied in blasting and other directions, and can solve problems such as inability to accurately control blasting rock particle size, embankment slope smooth surface effect and stability, steep terrain, complex landform, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] This embodiment is a further illustration of the present invention, rather than a limitation of the present invention.

[0061] The process of blasting the subgrade in this embodiment is as follows:

[0062] 1. Calculation of blasting parameters

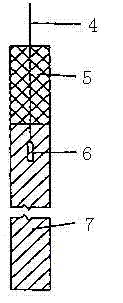

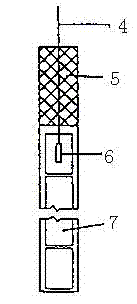

[0063] For areas with large excavation depths, the degree of weathering of rocks varies with the excavation depth. The greater the excavation depth, the harder the rocks, the greater the difficulty of blasting, the easier it is to leave roots, and the rate of large blocks also increases. For medium and deep hole blasting, its parameters should be accurately grasped to avoid unnecessary losses. For medium and deep hole blasting, the blasting parameters mainly include the blasting parameters of the intermediate body, namely the blasting parameters of the groove and the blasting parameters of the slope.

[0064] 1. Grooving blasting parameters:

[0065] Unit consumption (2# rock explosive): due to the low degree of weathe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com