A zero-fill black cotton soil subgrade treatment method

A technology of zero-filling black cotton and soil subgrades, which is applied in roads, roads, buildings, etc., can solve the problems of poor water stability of subgrades and reduce environmental pressure, and achieve the effects of reducing environmental pressure, saving engineering costs, and maintaining water and soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

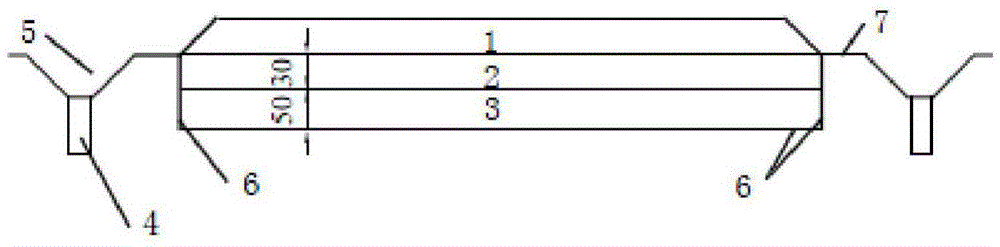

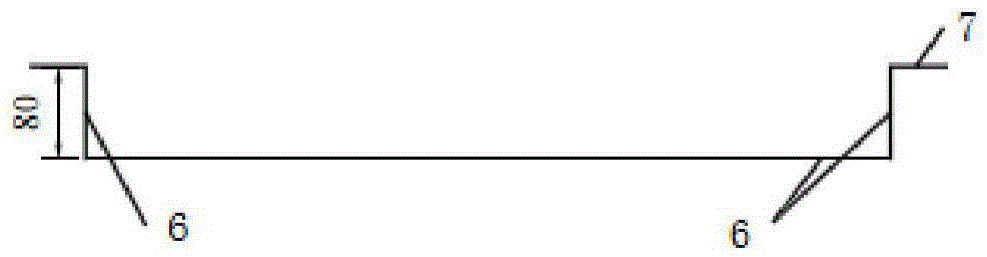

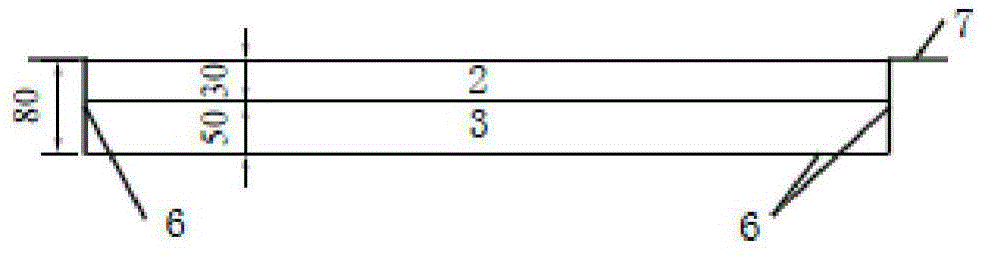

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but they are not intended to limit the present invention, but are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

[0023] The treatment method of zero-filled black cotton soil subgrade provided by the invention comprises the steps of: spraying sodium dodecylbenzene sulfonate dissolved in lime water on the bottom and sides after excavating 80 cm of the subgrade, and filling the dodecylbenzene sulfonate in layers Sodium alkylbenzene sulfonate treats 50cm of black cotton soil and 30cm of gravel soil, then paves the pavement structure, and sets gravel blind ditch under the side ditch.

[0024] The present invention also provides a treatment method for zero-filled black cotton soil subgrade, which method comprises the following steps in sequence:

[0025] Step 1: Subgra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com