Preparation and application of molybdenum blue micro-tube based on Keggin type silicotungstate

A technology of silicotungstate and micron tubes, which is applied in the directions of crystal growth, solution from liquid solvent at room temperature, single crystal growth, etc., can solve the problem of oxidation, substituted heteropoly blue micron tubes which have not been reported, and heteropoly blue micron tubes. Problems such as difficulty in using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

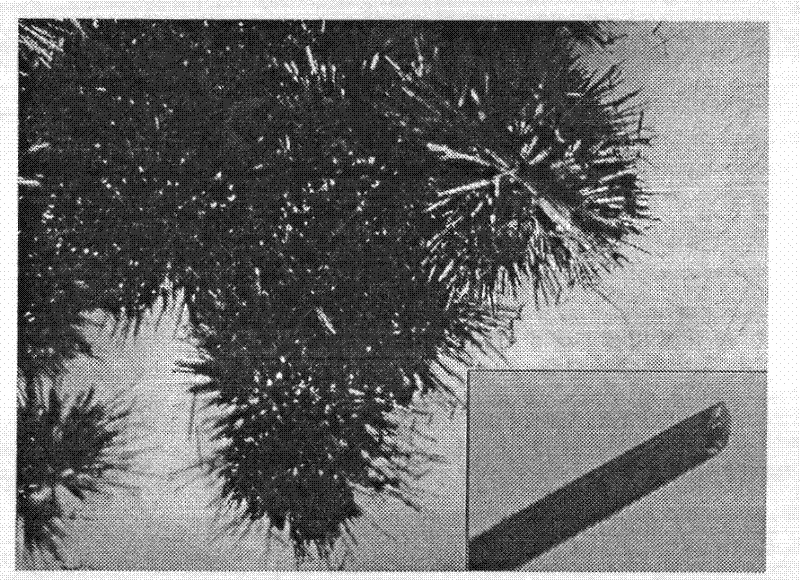

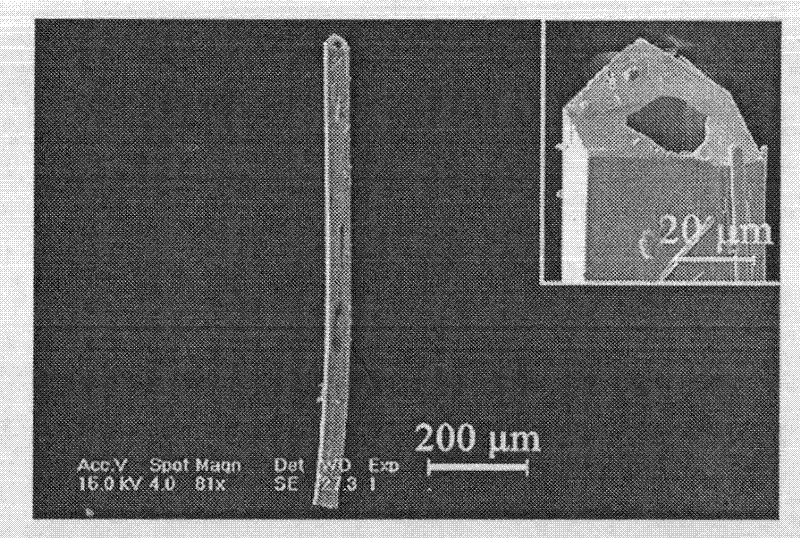

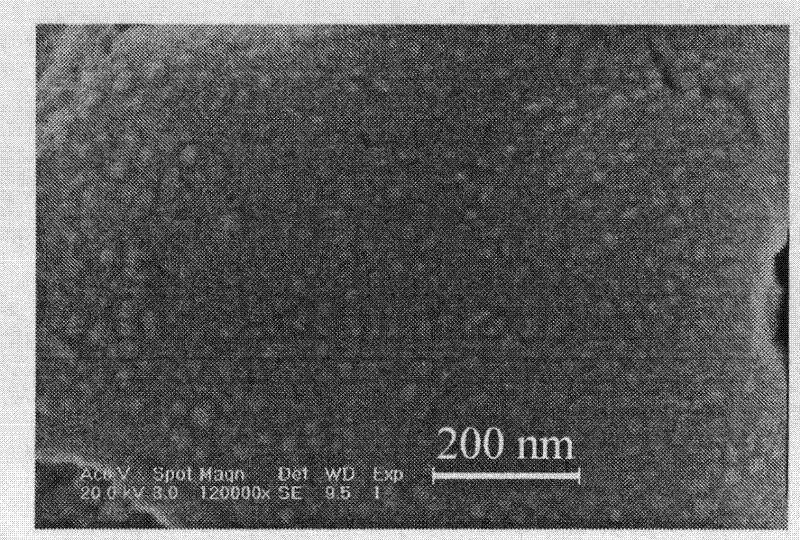

[0020] 3g of α-potassium silicotungstate (α-K 8 SiW 11 o 39 ) and 0.1g sodium molybdate (Na 2 MoO 4 )(K 8 SiW 11 o 39 and Na 2 MoO 4 The mass ratio is 30:1), dissolved in 10mL of water, adjusted to pH=1 with hydrochloric acid (HCl), the solution was placed in a 70°C water bath and heated, and 0.3g of ascorbic acid (ascorbic acid and K 8 SiW 11 o 39 The mass ratio is 1:10) for reduction, and after cooling to room temperature, a molybdenum blue microtube based on Keggin type silicotungstate is obtained.

Embodiment 2

[0022] 3g of α-potassium silicotungstate (α-K 8 SiW 11 o 39 ) and 0.15g sodium molybdate (Na 2 MoO 4 )(K 8 SiW 11 o 39 and Na 2 MoO 4 The mass ratio is 20:1), dissolved in 10mL water, with phosphoric acid (H 3 PO 4 ) to adjust the pH=1.5, place the solution in an 80°C water bath and heat, add 0.6g ascorbic acid (ascorbic acid and K 8 SiW 11 o 39 The mass ratio is 2:10) for reduction, and after cooling to room temperature, a molybdenum blue microtube based on Keggin type silicotungstate is obtained.

Embodiment 3

[0024] 3g of α-potassium silicotungstate (α-K 8 SiW 11 o 39 ) and 0.2g sodium molybdate (Na 2 MoO 4 )(K 8 SiW 11 o 39 and Na 2 MoO 4The mass ratio is 15:1), dissolved in 10mL of water, adjusted to pH=2 with hydrochloric acid (HCl), the solution was heated in a water bath at 90°C, and 0.9g of ascorbic acid (ascorbic acid and K 8 SiW 11 o 39 The mass ratio is 3:10) for reduction, and after cooling to room temperature, a molybdenum blue microtube based on Keggin type silicotungstate is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com