Piston four-way reversing valve for refrigerating system

A four-way reversing valve, refrigeration system technology, applied in valve details, valve device, valve operation/release device, etc., can solve problems such as oil film piston stuck, avoid dry friction and increase service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

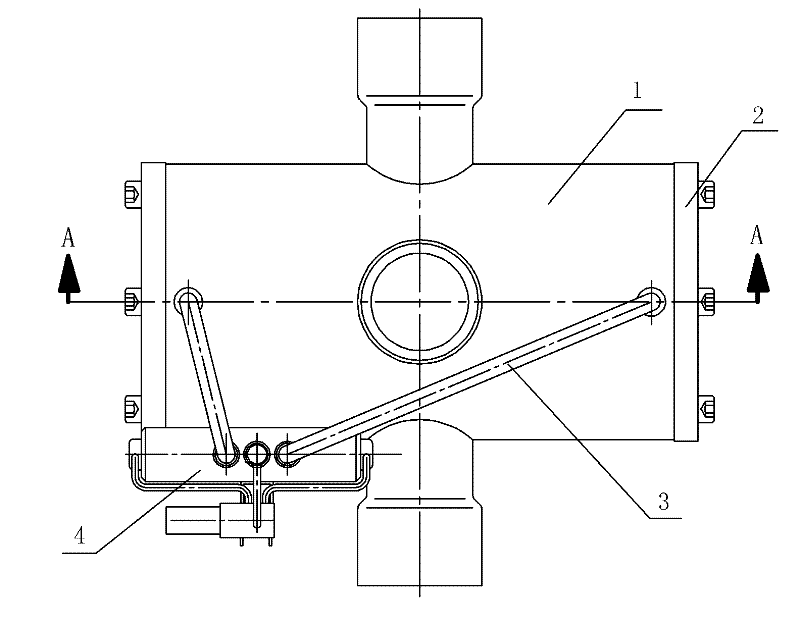

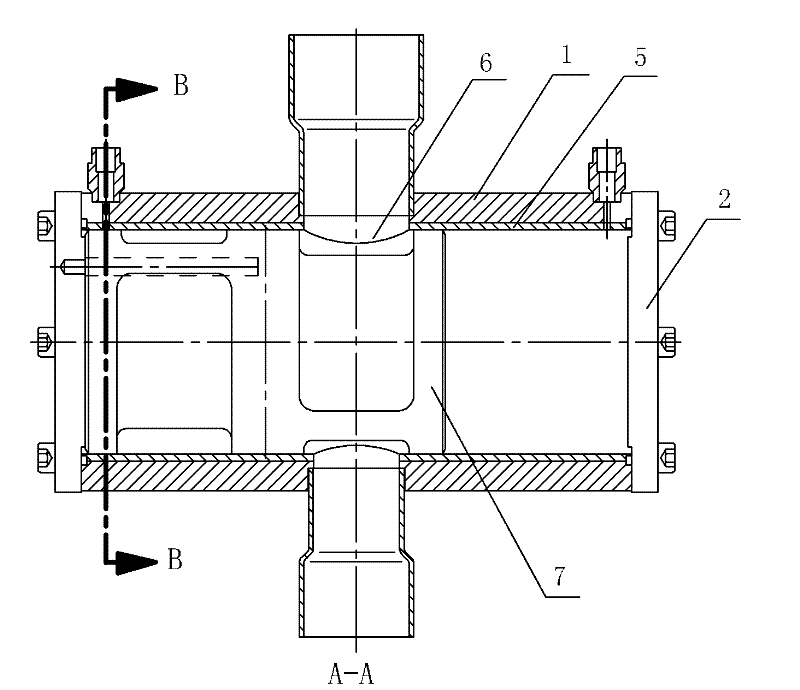

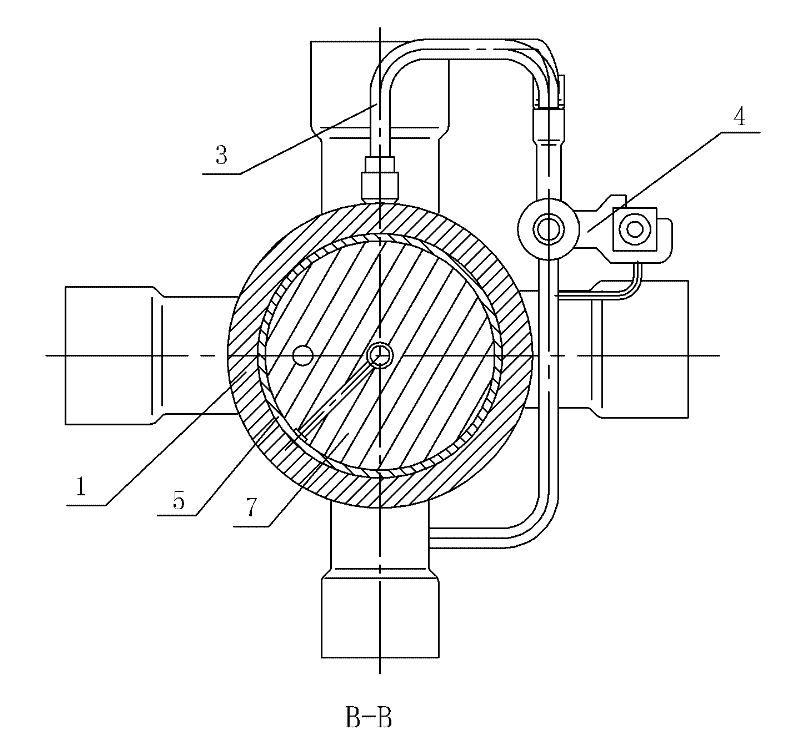

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] Such as Figure 1 to Figure 5 As shown, the present invention is mainly composed of a main valve and a pilot valve 4. The pilot valve 4 communicates with the cavity of the main valve through the air guide tube 3. The main valve includes a valve body 1, a piston 7 arranged in the valve body, and a piston 7 arranged on both sides of the valve body. Two end caps 2 at the end, four valve ports 6 are set on the valve body 1, and the piston 7 is composed of two I-shaped components rotated and staggered by 90 degrees to form a whole. The lubricating sleeve 5 is fixedly connected with the valve body 1. The lubricating sleeve 5 is provided with a through hole 9 corresponding to and communicating with the valve port 6. The lubricating sleeve 5 is divided into three layers from the outside to the inside in the radial direction. The first layer is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com