Method for machining joint with deep and narrow groove complicated structure

A technology with complex structures and processing methods, applied in metal processing equipment, manufacturing tools, milling machine equipment details, etc., can solve problems such as milled parts, lug thickness or groove width out of tolerance, easy to produce chattering tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

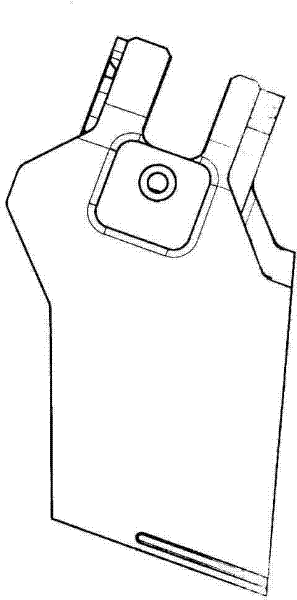

Image

Examples

Embodiment Construction

[0026] A method for processing joints with complex structures of deep and narrow grooves, characterized by comprising the following steps:

[0027] 1) In the design, the joint web is extended, and a positioning hole is set on the extended web, and the hole is used as the origin of the process for processing, and each processing process is based on the origin of the process, which reduces the difficulty of clamping and makes The tooling is simplified, the processing process is clear, and the processing origin is unified during the processing of each surface, which reduces the impact of multiple positioning on the quality of the parts;

[0028] 2) Processing of parts web:

[0029] 2.1) Roughly machine the shape and inner shape of the front of the part;

[0030] 2.2) The part is turned over, and the internal shape of the reverse side of the part is initially processed;

[0031] 2.2) The part is turned over, and the inner shape and shape of the front are finished;

[0032] 2.3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com