Evaporation concentration system combining vapor compressor and high-temperature heat pump

An evaporative concentration system and a vapor compressor technology, applied in evaporation, chemical instruments and methods, separation methods, etc., can solve the problems of heat waste, large size, and high investment in concentrated solutions and condensed water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The structure of the present invention will be further described below in conjunction with the accompanying drawings and through embodiments. It should be noted that this embodiment is illustrative rather than limiting.

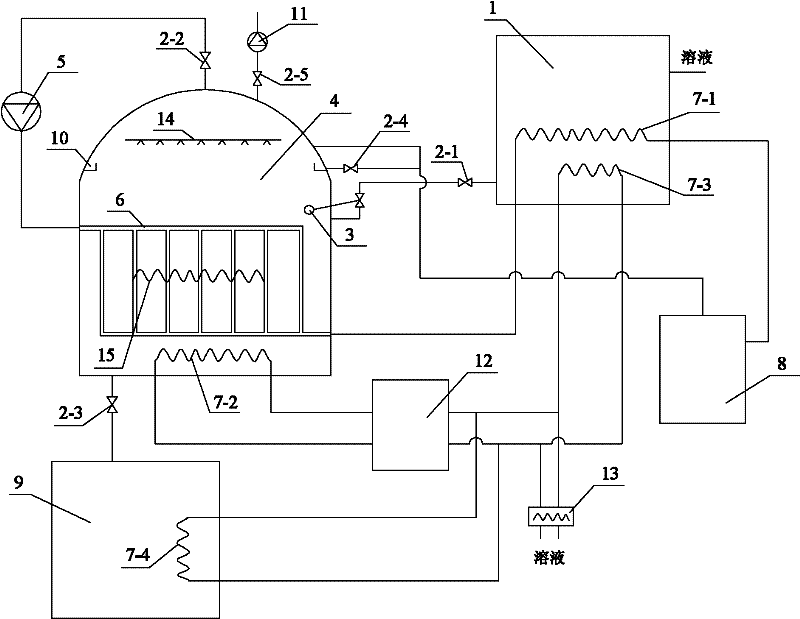

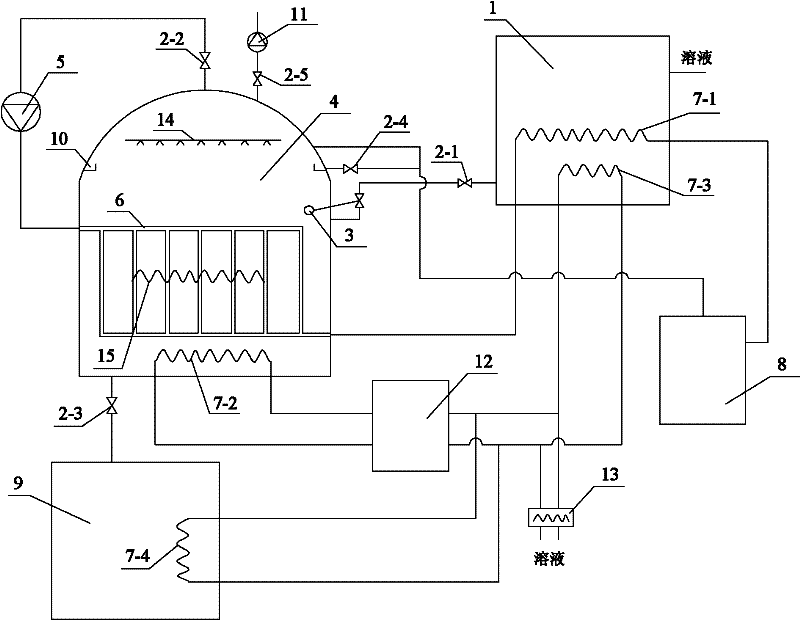

[0013] as the picture shows. The evaporation concentration system combined with steam compressor and high temperature heat pump, its structural composition is: the outlet of the liquid supply tank 1 is connected to the solution side inlet of the steam generator 4 through the first stop valve 2-1 and the float valve 3; the steam generator 4 The steam outlet of the steam outlet is connected to the steam compressor 5 and the inlet of the evaporation condenser 6 in the steam generator 4 in turn through the second stop valve 2-2, and the outlet of the evaporation condenser 6 is connected in series to the first in the liquid supply tank 1 through the pipeline. A coil heat exchanger 7-1 and fresh water tank 8. The liquid outlet of the steam generator 4 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com