Application of cold-adapted protease MCP-01 for tenderizing meat

A technology of MCP-01 and cold-adapted protease, which is applied in application, food preparation, food science, etc., can solve problems such as no mention effect, achieve good fresh color and water holding capacity, good application potential, maintain fresh color and long-lasting water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The method for preparing the cryogenic protease MCP-01 from the deep-sea psychic bacterium Pseudoalteromonas strain SM9913, the steps are as follows:

[0042] 1. Preparation of Liquid Seeds

[0043] 1 part of peptone, 0.5 parts of yeast powder, 1.5 parts of agar, 100 parts of artificial seawater, pH 7.0-7.2 (all parts by weight) were used to prepare a solid medium. After the culture medium was sterilized and cooled, the deep-sea psychrotroph Pseudoalteromonas strain (Pseudoalteromonas) SM9913 was inoculated by streaking on the inclined surface of the test tube, and cultured at 12-15° C. for 48-70 hours. Inoculate above-mentioned bacterial classification in the 500ml Erlenmeyer flask that 150ml liquid culture medium is housed (formula is the same as solid culture medium, do not add agar), 12~15 ℃, 200 revs shaking culture 24 hours, use as liquid seed.

[0044] 2. Preparation of cold-adapted protease preparation by liquid submerged fermentation

[0045] 3.5-4.0 parts of b...

Embodiment 2

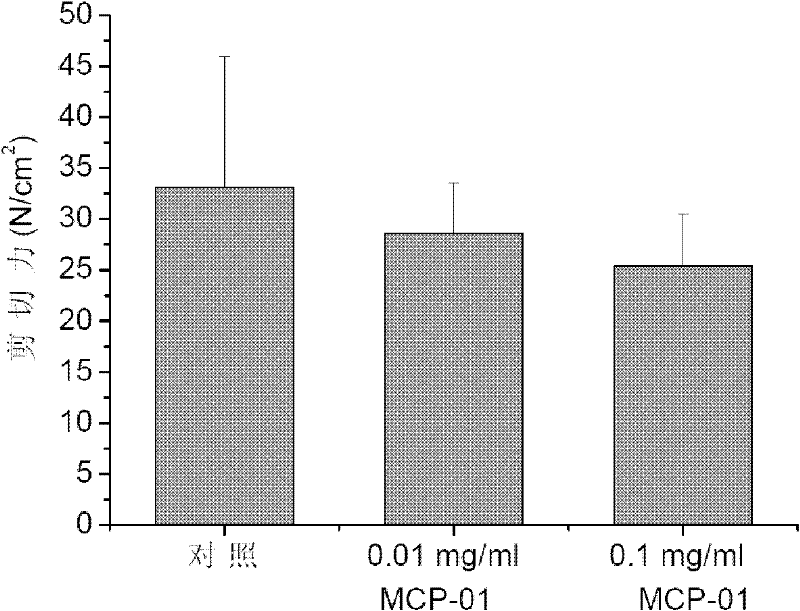

[0060] The application of cold-adapted protease MCP-01 in the tenderization of meat products, the steps are as follows:

[0061] (1) the cold-adapted protease MCP-01 that step 3 is prepared is mixed with the cold-adapted protease MCP-01 solution that concentration is 10 μ g / ml and 100 μ g / ml;

[0062] (II) After the bovine breast muscle is washed, it is immersed in the cold-adapted protease MCP-01 solution prepared in step (I), and stored at 4° C. for 20 hours.

[0063] The results showed that the shear force of bovine breast muscle decreased significantly after adding cold-adaptive protease MCP-01 at 4°C for 20 hours, while the shear force of bovine breast muscle in the control group without cold-adaptive protease did not decrease significantly. (Such as image 3 ).

[0064] The bovine breast muscle was treated with the same concentration of bromelain and papain at 4°C for 20 hours, and then the water loss rate was measured. Define the water loss rate as:

[0065]

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com