Fully-automatic board feeding optical image detecting device for PCB (printed circuit board)

A technology of PCB circuit board and optical image, which is applied in the field of automatic optical image detection device of PCB circuit board, can solve the problems of complex structure, low degree of automation and high manufacturing cost of the detection device, and achieves compact structure, high degree of automation and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

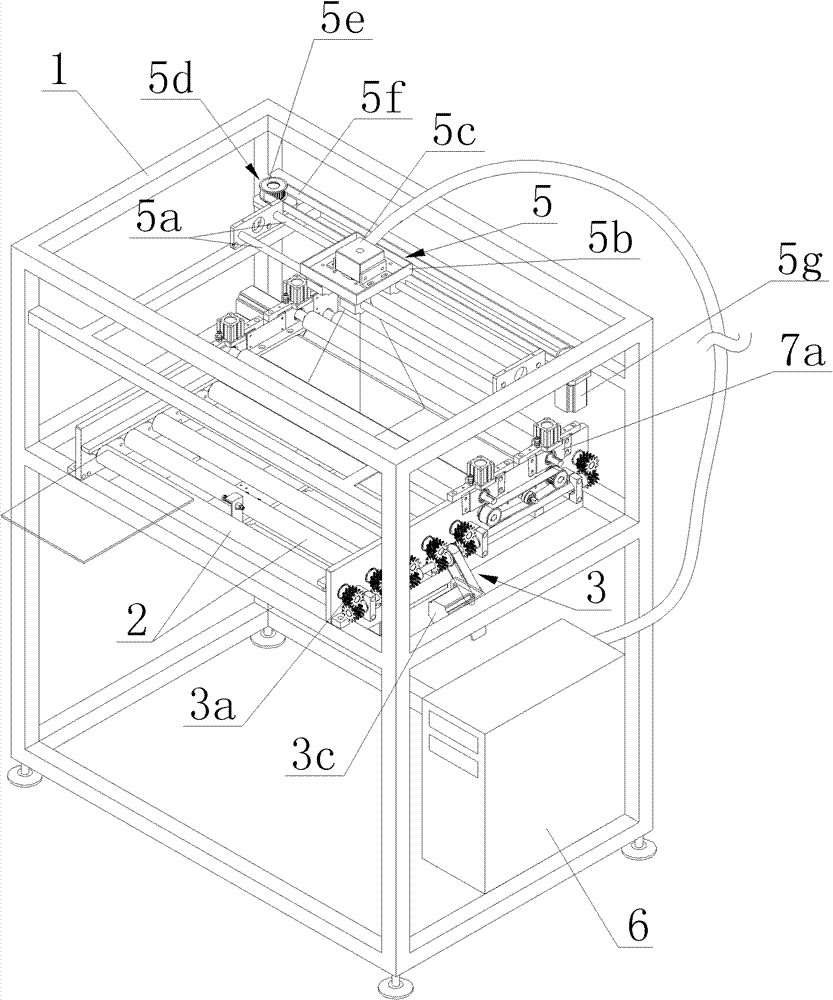

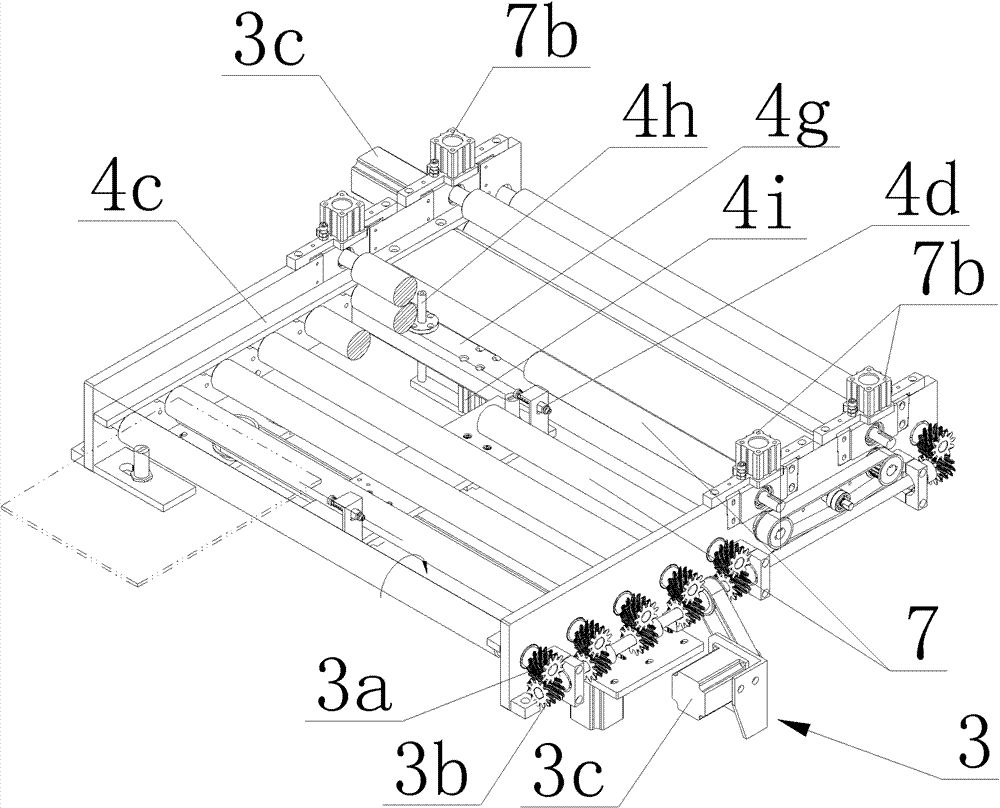

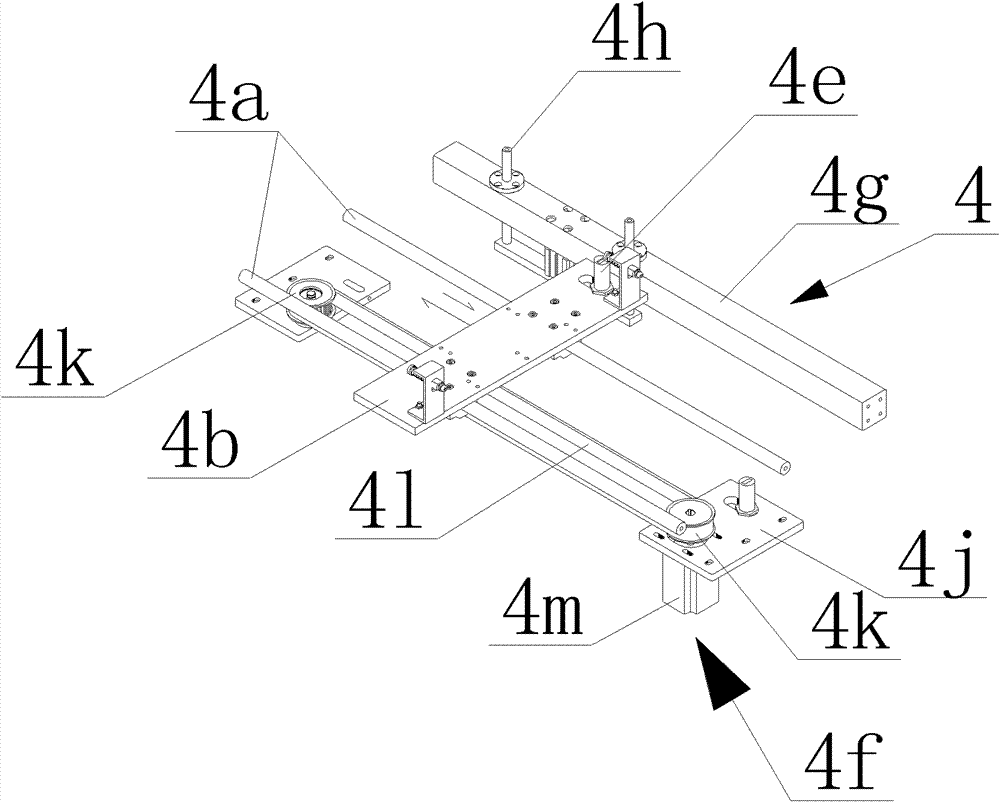

[0020] refer to Figure 1 to Figure 4 As shown, a kind of PCB circuit board automatic board-feeding optical image detection device of the present invention comprises a frame 1, on the frame 1 is provided with a plurality of horizontally parallelly arranged board-feeding rollers 2, and the board-feeding rollers 2 adopt friction coefficient Made of larger rigid material, the plate feeding roller 2 is connected with a rolling drive device 3, and the rolling driving device 3 consists of a driven helical gear 3a arranged at one end of each plate feeding roller 2, and a corresponding driven helical gear 3a. The driving helical gear 3b and the driving device 3c connected with the driving helical gear 3b are formed, the driving helical gear 3b is connected through a fulcrum, and the driving device 3c is linked with the fulcrum through a transmission belt; the driving device 3c is a stepping motor or Any one of the servo motors, the present embodiment adopts a stepper motor as the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com