Drying device for EVA (Ethylene Vinyl Acetute) sample crosslinking degree test

A technology of drying device and cross-linking degree, which is applied in the direction of drying solid materials, method combination to dry solid materials, drying, etc., which can solve the problems of harming operators, poisoning, and operator injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

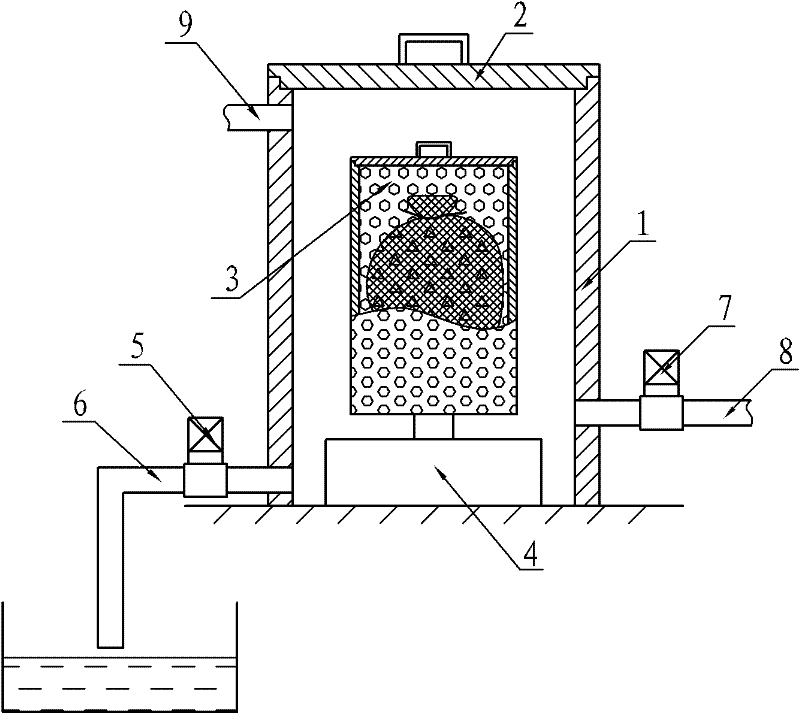

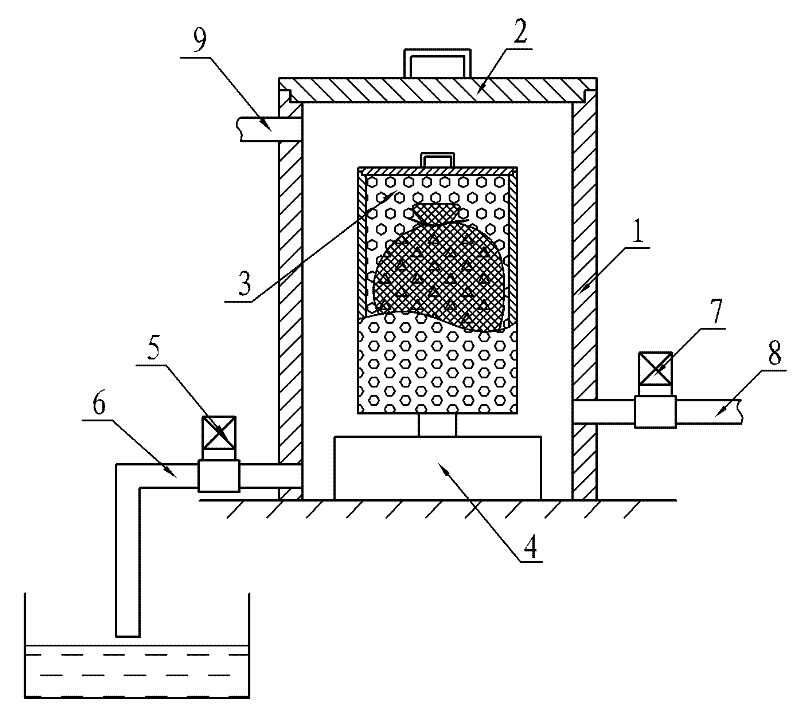

[0013] A kind of drying device for EVA sample cross-linking degree test, such as figure 1 As shown, it includes a heat preservation oven 1, a box cover 2, a liquid removal bucket 3, a motor 4, a liquid discharge electromagnetic reversing valve 5, a liquid discharge pipe 6, an air transmission electromagnetic reversing valve 7, a hot air intake pipe 8 and a hot air exhaust The pipe 9 is provided with a dehydration barrel 3 in the airtight heat preservation oven 1, and the liquid dehydration barrel 3 is driven by a motor 4. The bottom of the airtight heat preservation oven 1 is equipped with a liquid discharge pipe 6 and a hot air inlet pipe 8, and the liquid discharge pipe 6 and the hot air inlet The location requirements of the air pipe 8 are: the liquid discharge pipe 6 is located below the hot air intake pipe 8 in the height direction, the liquid discharge pipe 6 communicates with the inner cavity of the airtight heat preservation oven 1 through the liquid discharge electroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com