Foam metal composite sand prevention structure and liquid extracting pipe

A foam metal and sand control technology, which is applied in the fields of production fluids, wellbore/well components, earthwork drilling, etc., can solve the problems of poor filter layer permeability and poor diversion effect, and achieve good sand control effect and improve sand control. Effect and production efficiency, the effect of strong sand holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

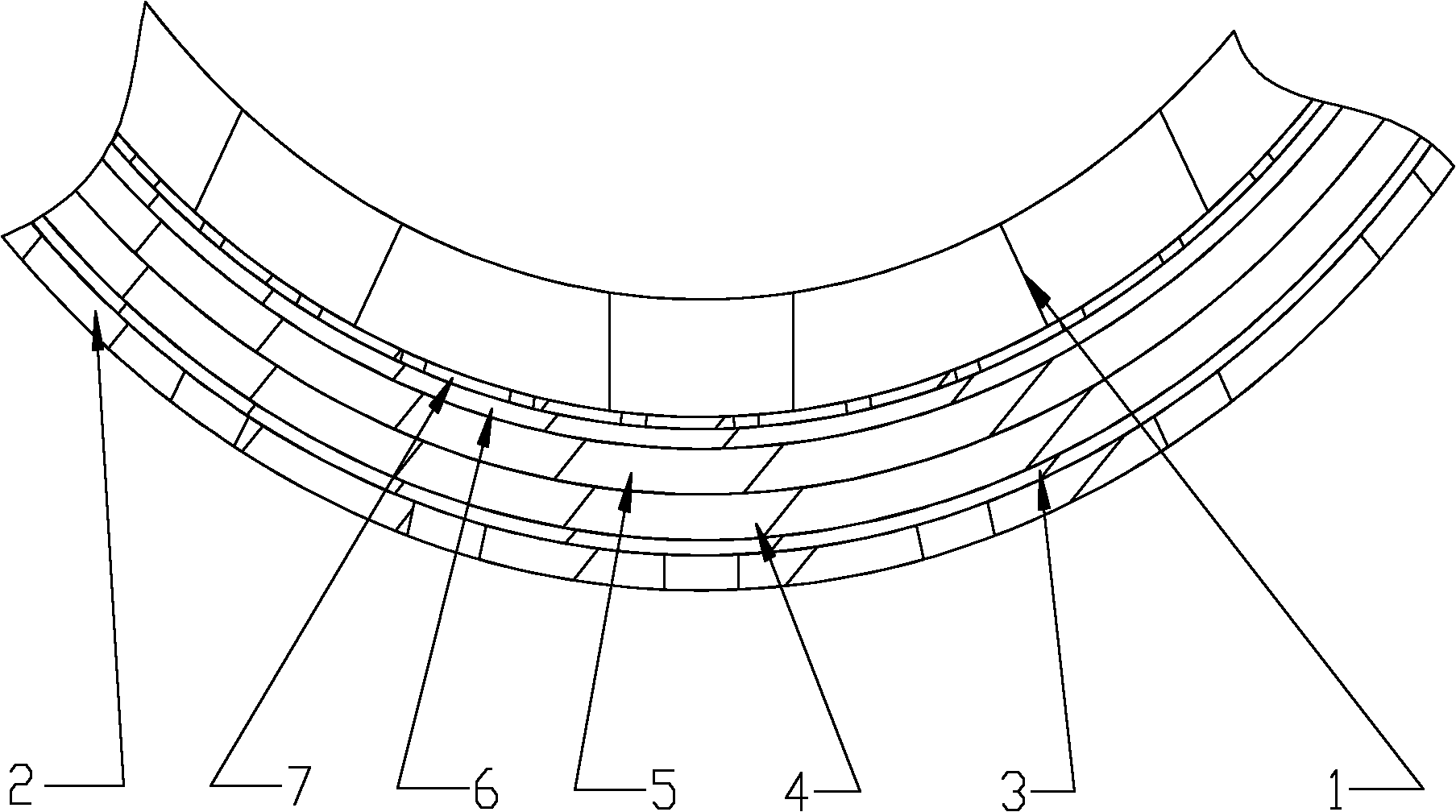

[0034] like figure 2 and image 3 As shown, the present invention proposes a metal foam composite sand control structure. The metal foam composite sand control structure is sleeved outside the base pipe 1. The metal foam composite sand control structure at least includes: a metal foam sand control layer made of metal foam.

[0035] The manufacturing process of the metal foam sand control layer includes: conductively treating polyurethane sponges with different porosities, depositing metal on the sponges through electrodeposition, sintering at high temperature to strengthen the electroplating layer and burning the sponges. The manufacturing process of metal foam is already a prior art, and will not be repeated here. The metal f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com