Detachable natural gas hydrate simulation sand production and sand prevention test reaction device and method

A reaction device and hydrate technology, applied in chemical instruments and methods, soil material testing, material inspection products, etc., can solve problems such as complex devices, difficulty in making experimental design schemes, and insufficient flexibility of simulation devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

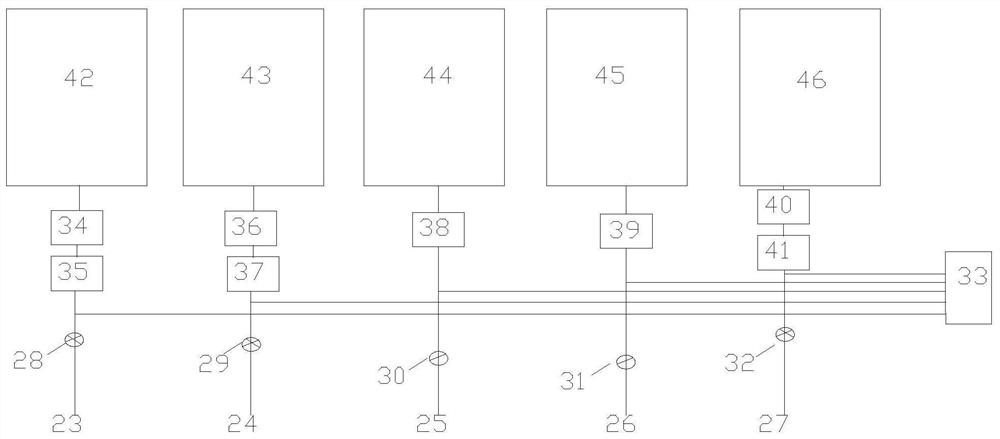

[0071]In this embodiment, in order to more clearly explain the combination characteristics of the reactor system of the present invention, the first reactor assembly, the second reactor assembly, and the third reactor assembly can be referred to as the left and right reactors, the second left and right reactors, and the central reactor respectively. Reactor, the reactor system can be referred to simply as the reactor. The production method can choose decompression production or heat injection production according to the needs. Among them, depressurization production is one of the main natural gas hydrate production methods at present. The lower phase equalizes the pressure, so that the hydrate decomposes from the solid to the phase transition to produce methane gas. The well design of decompression method is similar to that of conventional oil and gas production, and the pressure in hydrate reservoirs with better permeability spreads quickly. Therefore, depressurization method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com