Device for growing semiconductor crystals

A technology of a support device and a crystal growth furnace, which is applied in the field of III-V, can solve the problems of not being able to provide accurate and controlled heating of seed crystal wells, being lossy, and unable to solve the requirements of temperature gradient control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

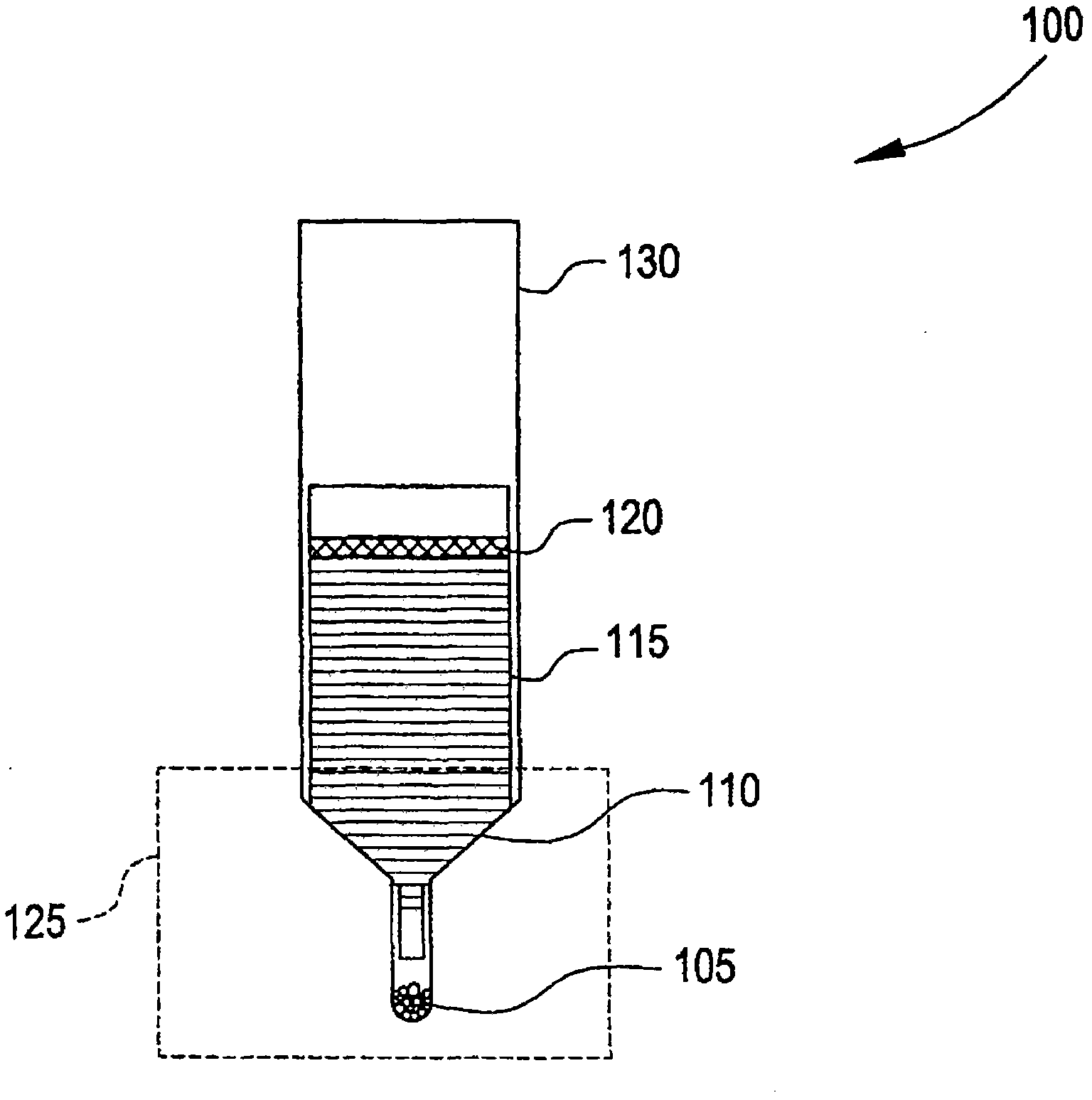

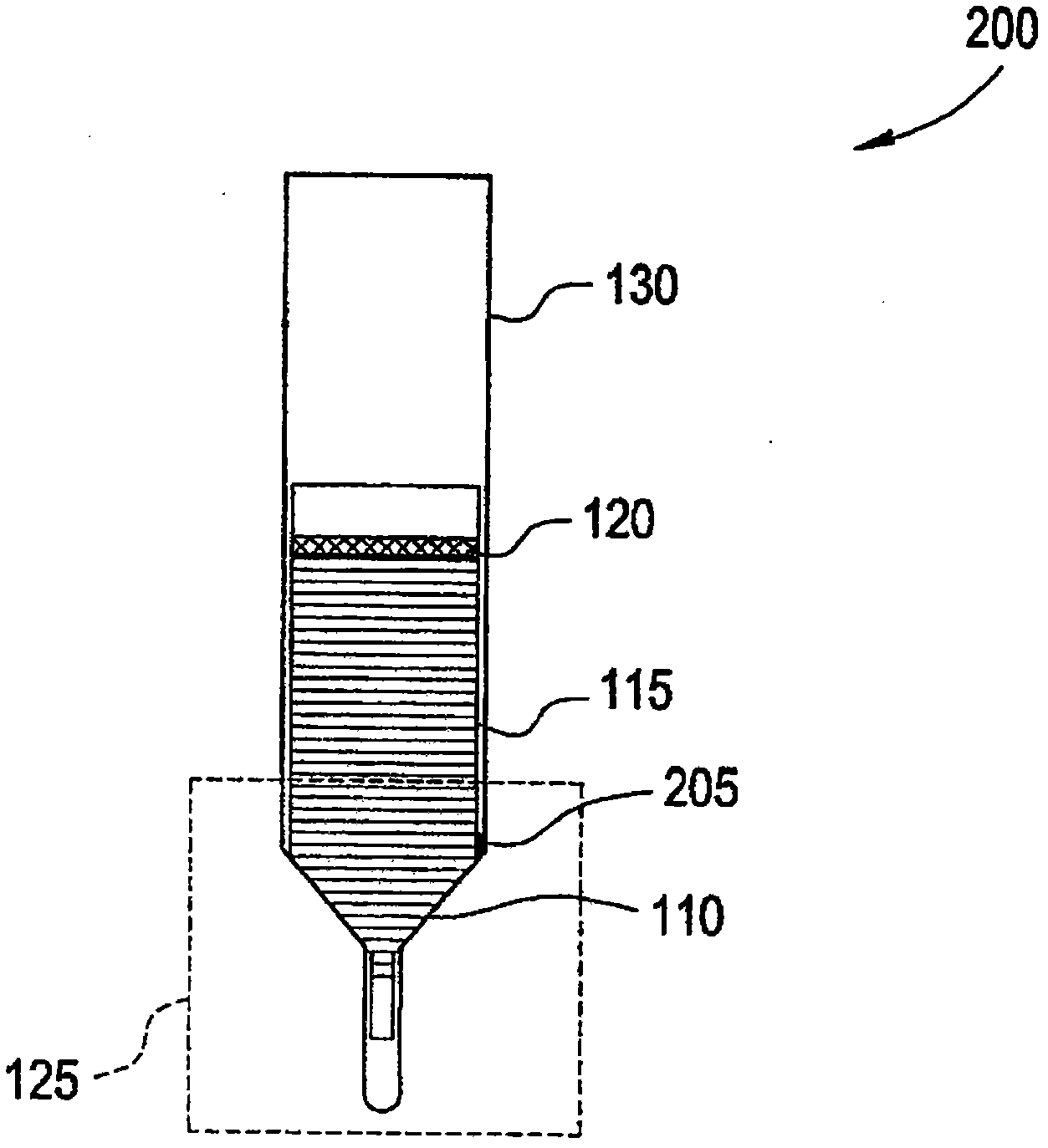

[0022] Exemplary embodiments of the invention generally relate to the growth of group III-V, II-VI, and related single crystal compounds under conditions with robust supports, doping and resistivity control, and temperature gradients. Using VGF growth of GaAs as an illustrative example, an embodiment of a method of carbon doping and resistivity control during a VGF growth process, and an embodiment of a method of setting a crucible holder in a VGF growth furnace are described below.

[0023] VGF involves crystal growth techniques, devices and process technologies for growing large single crystal ingots with very high structural uniformity and low defect density. In one embodiment, the boule is substantially cylindrical, having a diameter greater than 4 inches and a length greater than 6 inches. The substantially cylindrical crystals grow in a direction perpendicular to the seed crystal, which is under the polycrystalline feedstock.

[0024] In one embodiment, control of resis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com